Convenient fixing tubular product slotting machine

A technology for slotting machines and pipes, applied in clamping, positioning devices, metal processing machinery parts, etc., can solve the problems of troublesome clamping and positioning of pipe fittings, low slotting efficiency, affecting processing efficiency, etc., so as to facilitate batch processing, Improve efficiency and accuracy, and achieve the effect of batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

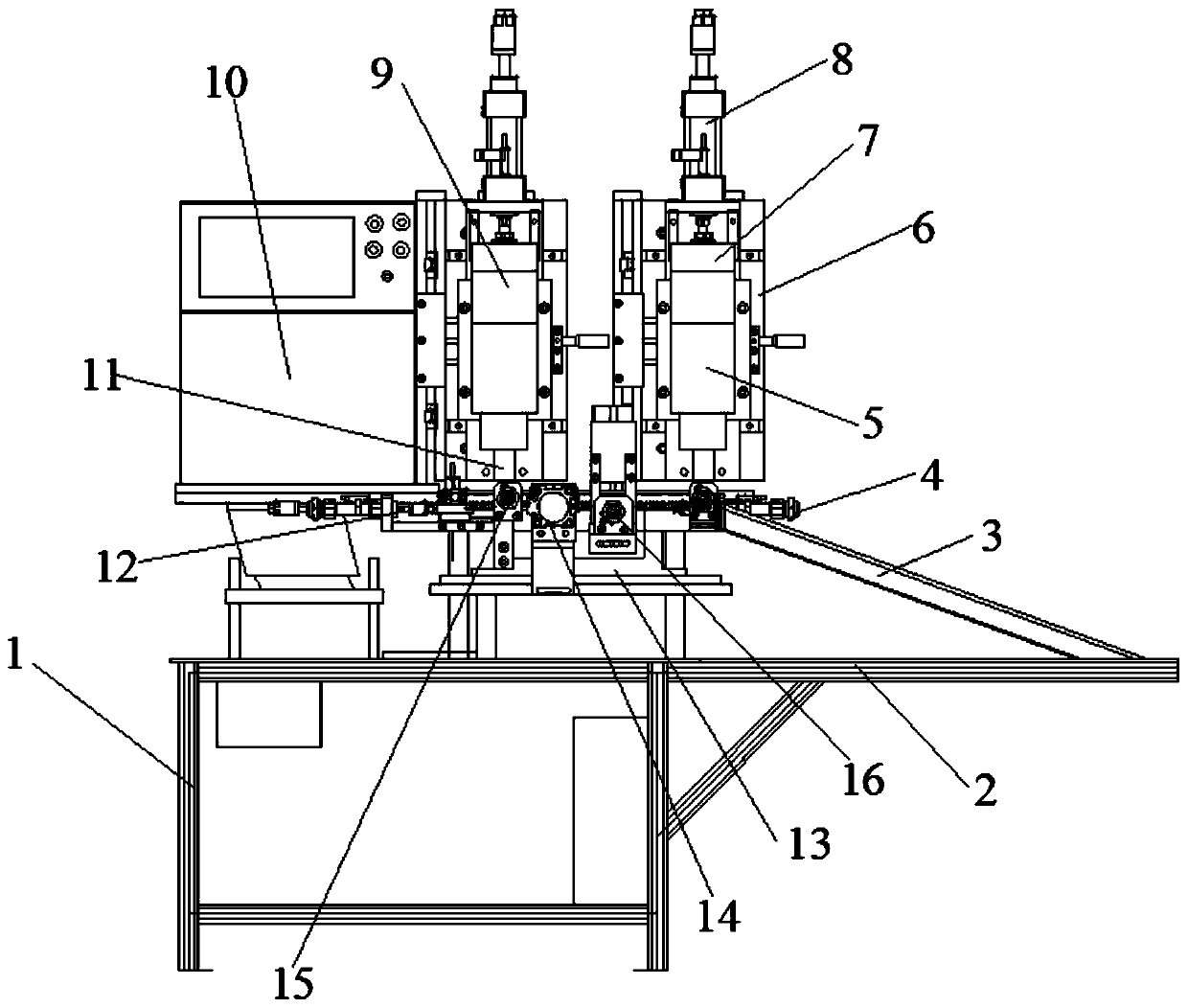

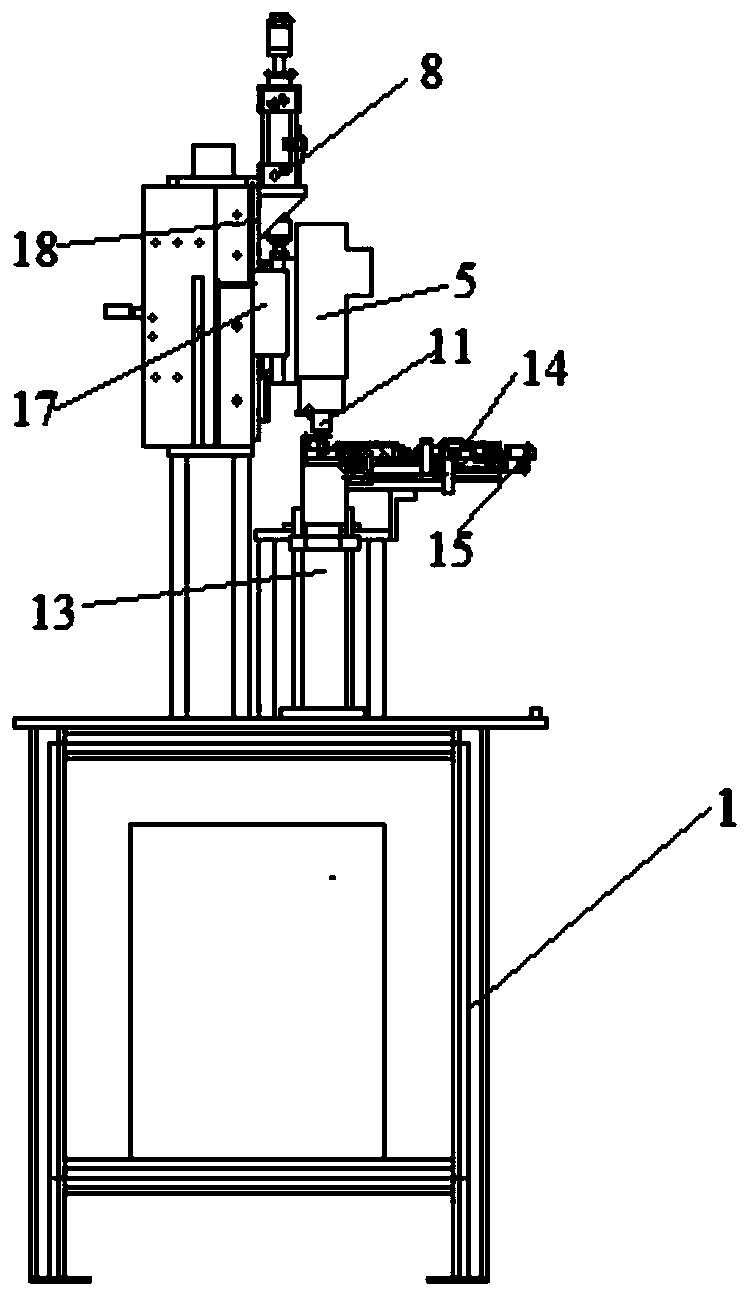

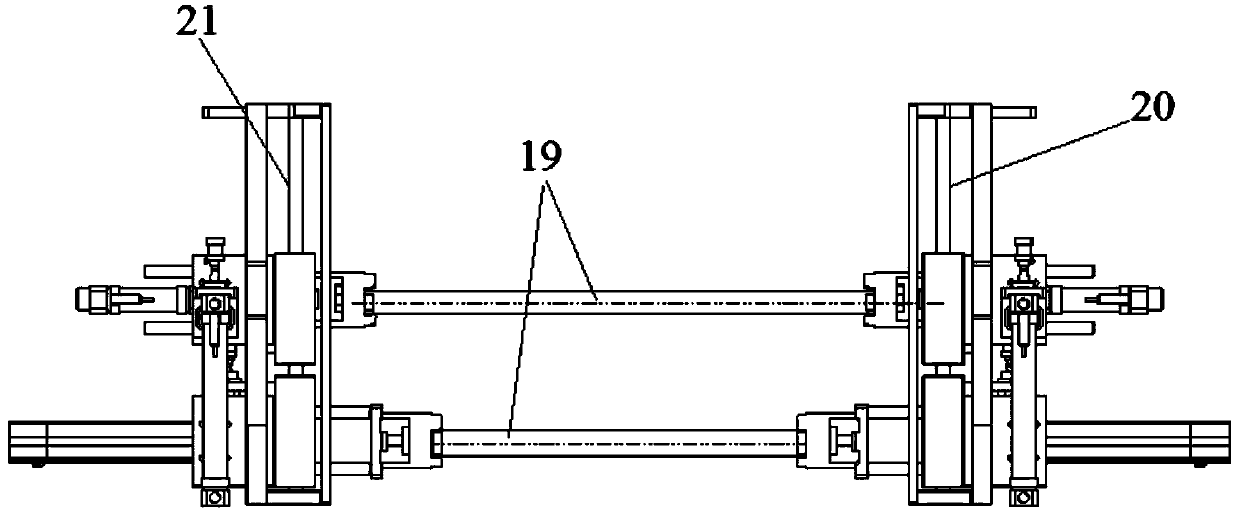

[0021] see Figures 1 to 4 , In the embodiment of the present invention, a convenient and fixed pipe slotting machine includes a machine base 1, an upper platen 2, a pipe feeding mechanism 3, a material receiving table, a first clamping mechanism 4, a second clamping mechanism 12, The main pushing material positioning mechanism 14, the first auxiliary material pushing material positioning mechanism 15 and the second auxiliary material pushing material positioning mechanism 16, wherein the top surface of the machine base is fixedly provided with the upper platen 2, and one side of the upper platen 2 is fixedly disposed There is the pipe feeding mechanism 3, the middle position of the upper platen is fixed and supported by a bracket 13, and the material receiving table is provided. The slotting machine 7 and the second slotting machine 9 are provided with a first clamping mechanism 4 and a second clamping mechanism 12 arranged side by side on the receiving table. The first clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com