Producing and machining process of high-speed rotor spindle

A high-speed rotor and processing technology, applied in the field of rotor shafts, can solve problems such as scrapping, resource and cost loss, and achieve the effects of quality assurance, less equipment consumption, and reduced scrapping probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

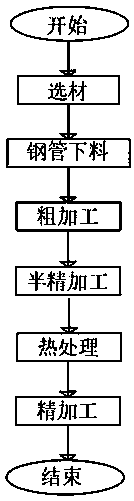

[0033] A production and processing technology of high-speed rotor shaft, such as figure 1 shown, including the following steps;

[0034] S1: material selection;

[0035] S2: round steel blanking;

[0036] S3: Rough machining;

[0037] S4: semi-finishing;

[0038] S5: heat treatment;

[0039] S6: Finishing;

[0040] S7: After the processing is completed, its appearance and performance are inspected.

[0041] The S1 selects No. 45 steel whose size is Φ180mm*2530mm round steel material.

[0042] In the above S3, most of the margin on the steel is removed, so that the shape and size of the steel are close to the finished parts, and a center hole is punched on the end face of the steel. The outer circle of the car is Φ176mm-Φ177mm, and the taper is required to be no more than 0.5 0.05.

[0043] In the above S4, the main surface has a certain finishing allowance, and the reserved amount at both ends of the rotor shaft is 5-10mm.

[0044] The heat treatment steps in the S5 a...

Embodiment 2

[0052] A production and processing technology of high-speed rotor shaft, such as figure 1 Shown: Include the following steps.

[0053] S1: material selection;

[0054] S2: round steel blanking;

[0055] S3: Rough machining;

[0056] S4: semi-finishing;

[0057] S5: heat treatment;

[0058] S6: Finishing;

[0059] S7: After the processing is completed, its appearance and performance are inspected.

[0060] The S1 selects No. 45 steel whose size is Φ180mm*2530mm round steel material.

[0061] In the above S3, most of the margin on the steel is removed, so that the shape and size of the steel are close to the finished parts, and a center hole is punched on the end face of the steel. The outer circle of the car is Φ176mm-Φ177mm, and the taper is required to be no more than 0.5 0.05.

[0062] In the above S4, the main surface has a certain finishing allowance, and the reserved amount at both ends of the rotor shaft is 5-10mm.

[0063] The heat treatment steps in the S5 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com