A kind of flexible unloading device

An unloading device and flexible technology, applied in the direction of pipe components, pipe supports, mechanical equipment, etc., can solve problems such as uneven unloading, damaged steel pipe bending, waste of resources, etc., and achieve the effects of avoiding waste, reducing vibration load, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

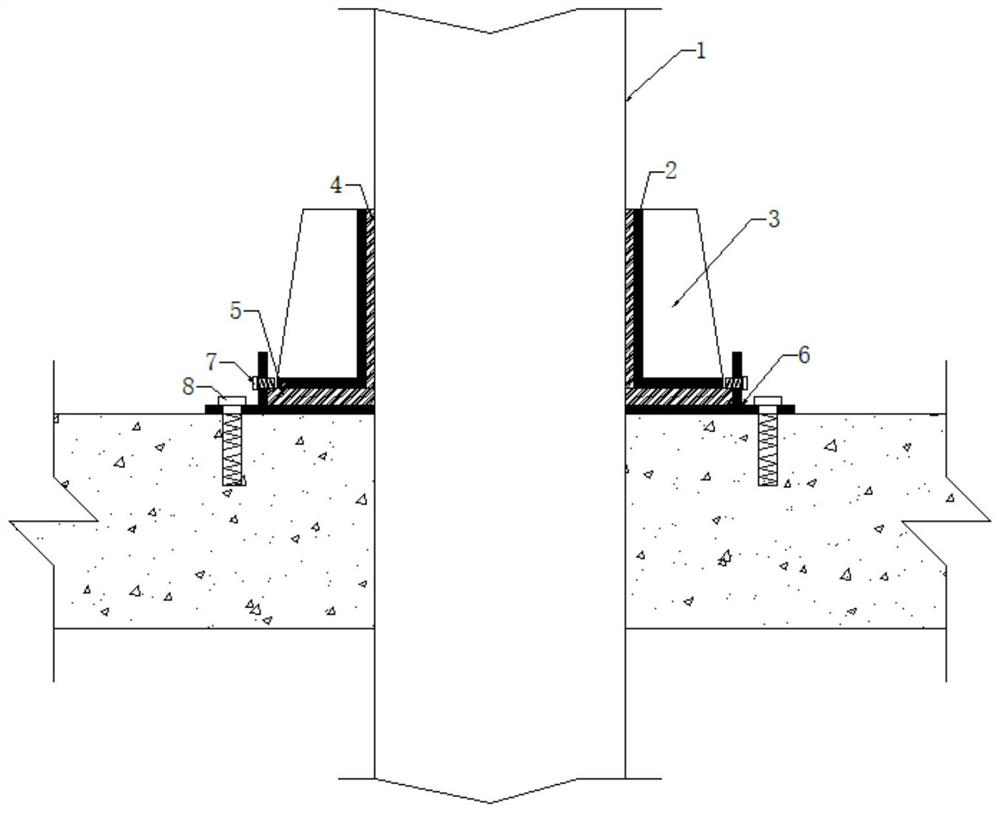

[0025] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] In this embodiment, the data used is the preferred solution, but is not intended to limit the present invention;

[0028] In this embodiment, taking the DN125 type high-pressure pump pipe as an example, the outer diameter of the pump pipe is 140mm, and the unloading device is designed;

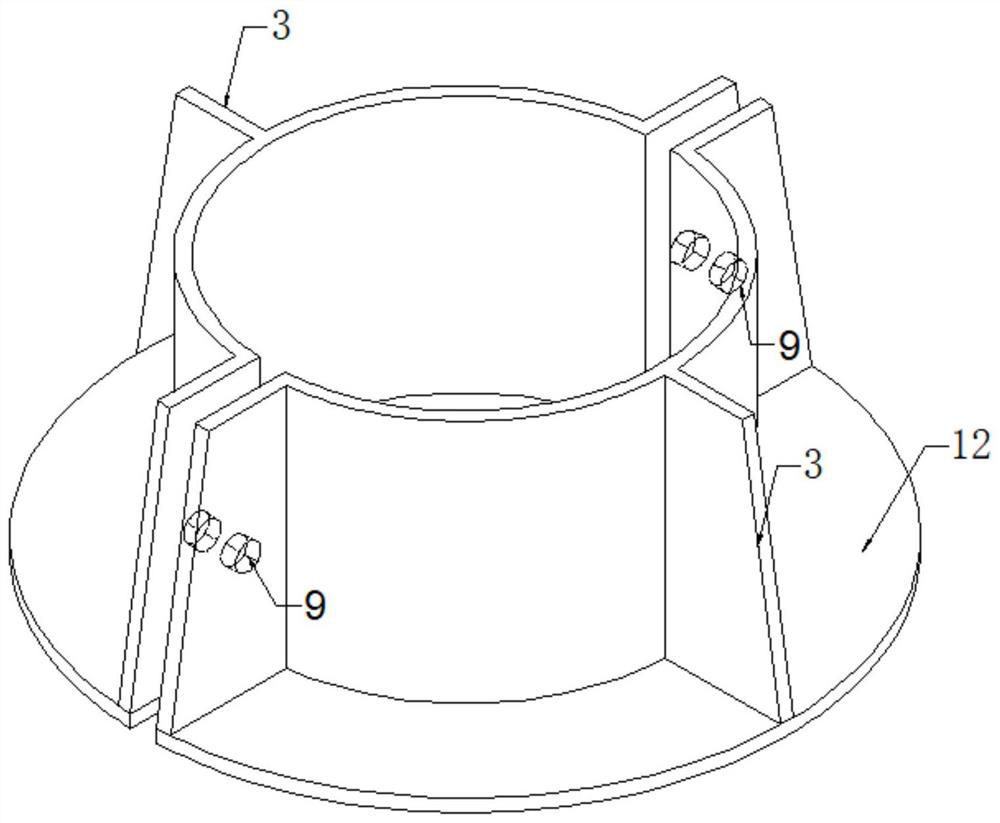

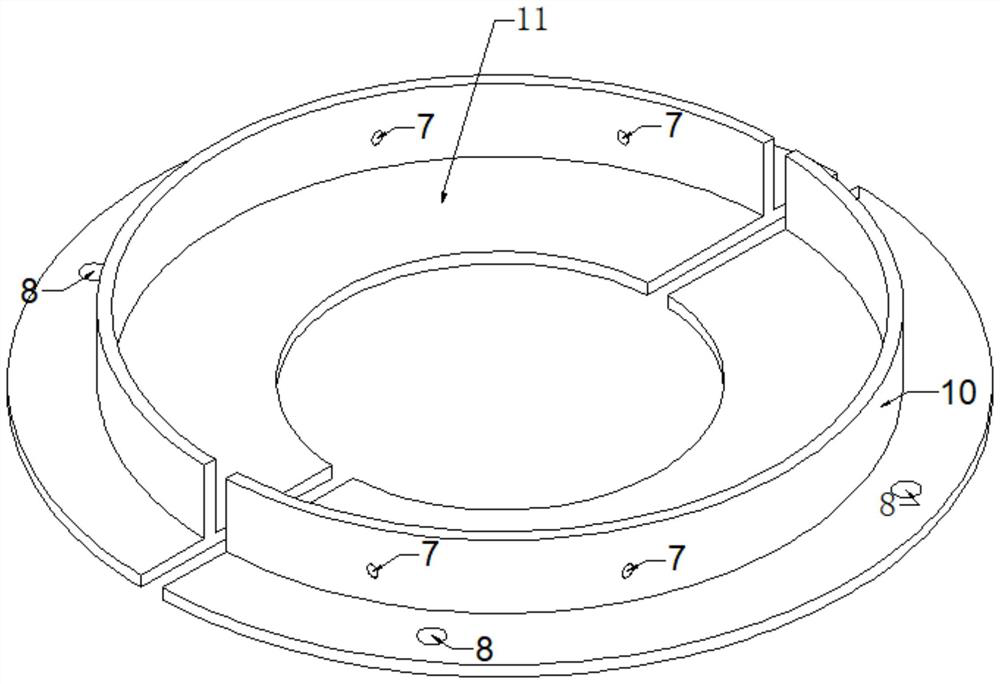

[0029] Such as Figure 1-5 as shown,

[0030] In this embodiment, the inner diameter of the rubber gasket is 140mm, the outer diameter is 150mm, and the height is 100mm, and the inner diameter of the joint surface of the force transmission device and the gasket is 150mm;

[0031] In this embodiment, the inner diameter of the rubber backing plate is 150 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com