Anti-discharging burner

A burner and anti-overflow technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problem of liquid entering the burner from the fire hole of the inner ring fire cover, blocking the fire hole, affecting the normal operation of the gas chamber, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

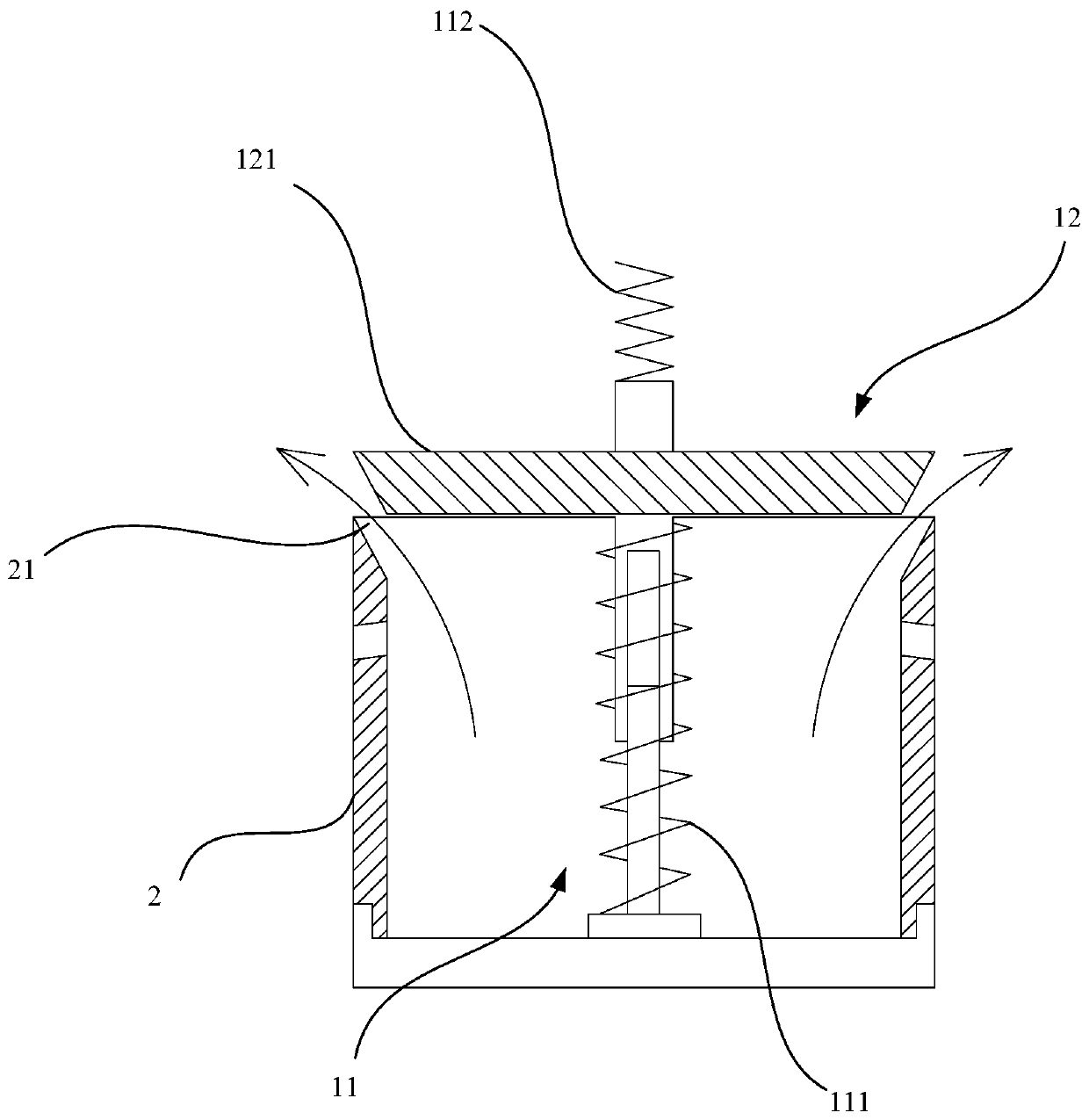

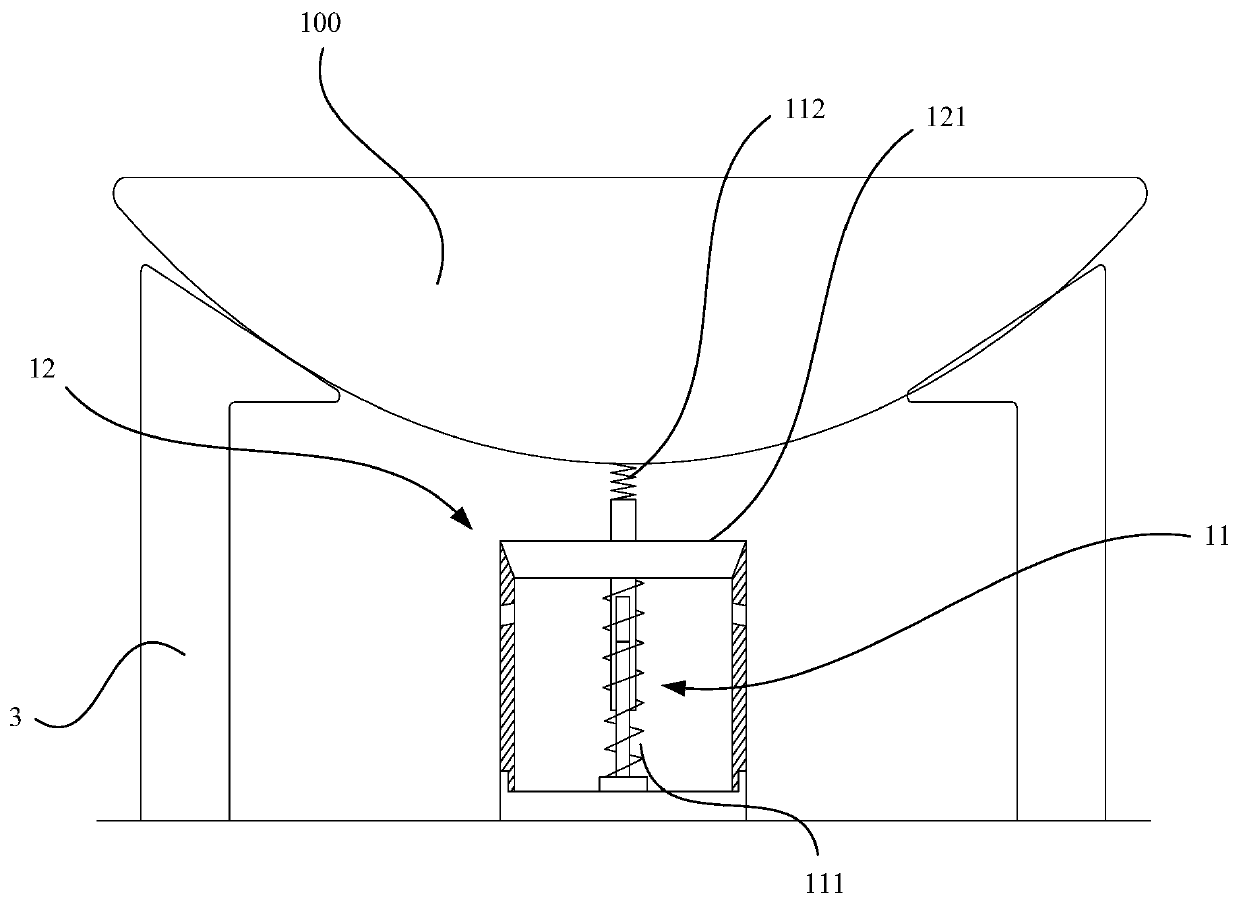

[0046] The invention provides an anti-spill burner, which includes an inner ring fire cover 2, a liquid-proof mechanism 1 and a pot support 3. Among them, the liquid-proof mechanism 1 is arranged on the inner ring fire cover 2, and the pot support 3 is arranged around the outside of the inner ring fire cover 2. When the pointed bottom pot 100 is placed on the anti-spill burner, the pointed bottom pot 100 is covered by the pot Supported by the bracket 3, the anti-liquid mechanism 1 closes the top fire hole 21 of the inner ring fire cover 2 after judging that the pointed bottom pot 100 is placed on the anti-overflow burner, so as to prevent liquid from entering through the top fire hole 21 when overflow occurs , and accumulate in the gas chamber of the inner ring fire cover 2, causing problems such as the failure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com