Fire cover

A fire cover and cover plate technology, applied in the direction of burner ignition device, gas fuel burner, combustion method, etc., can solve the problem of not being able to change the size of the maximum adjustable firepower range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

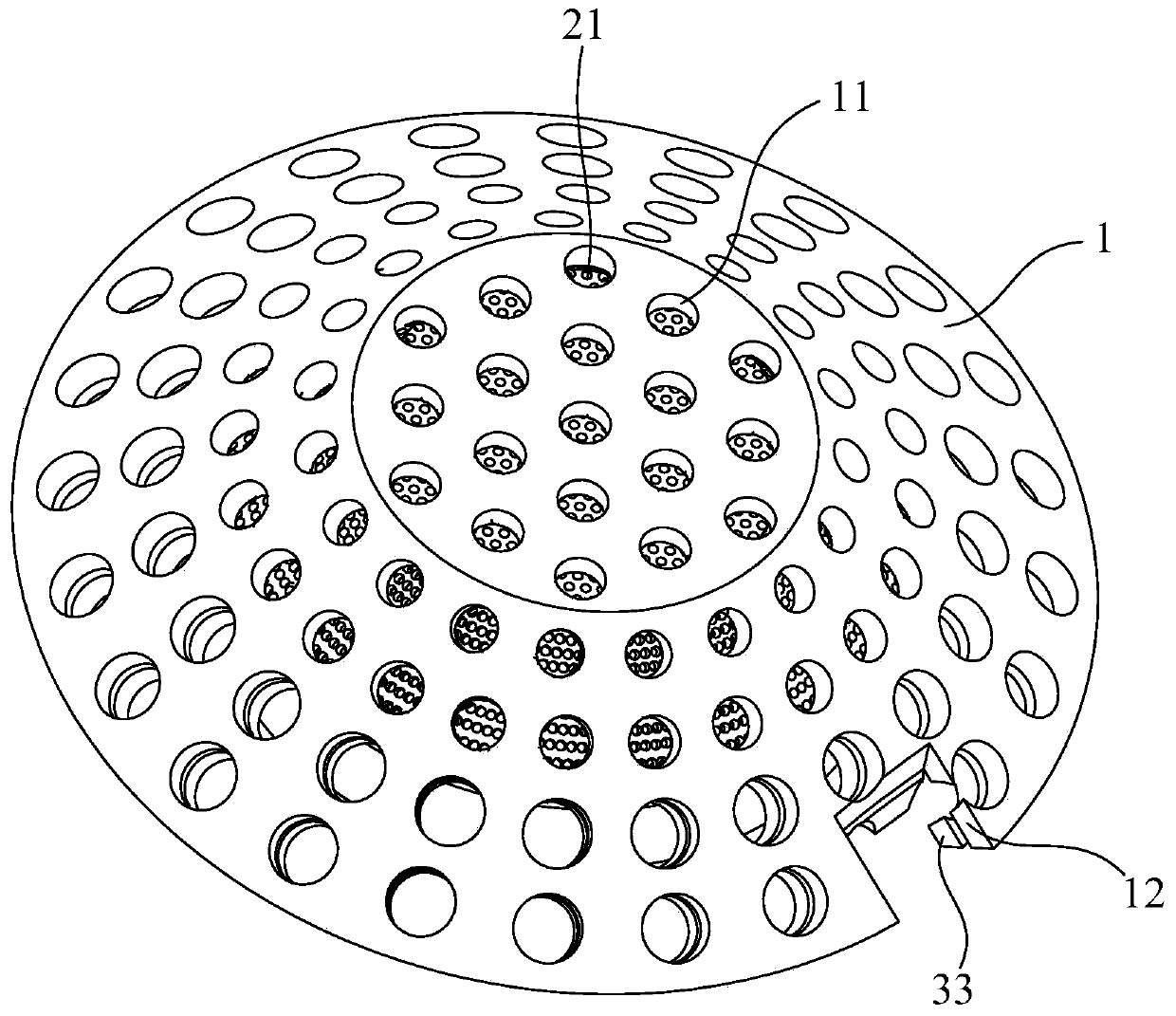

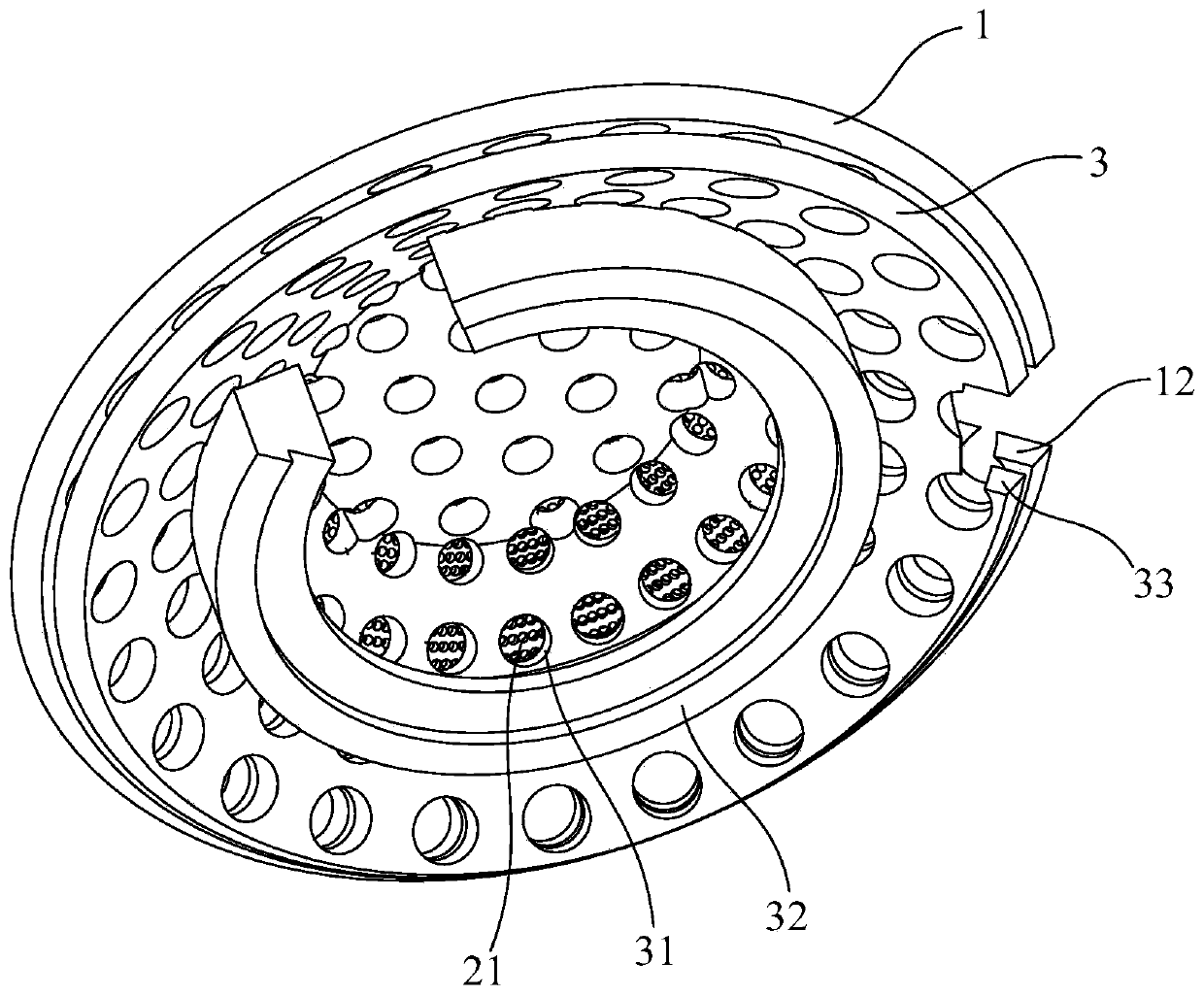

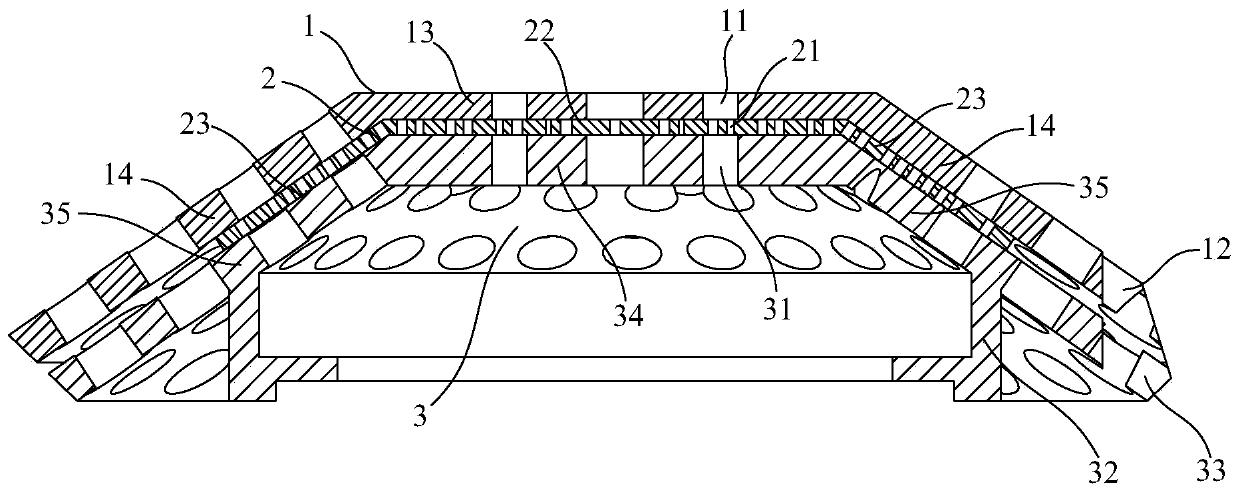

[0049] Figure 1 to Figure 6 Shown is Embodiment 1 of the fire cap of the present invention. The fire cover comprises a first cover plate 1 and a second cover plate 2, the first cover plate 1 is provided with some first fire holes 11; the second cover plate 2 is provided with some second fire holes 21, and the first cover plate 1 is covered on the second cover plate 2, the diameter of the second fire hole 21 is smaller than the diameter of the first fire hole 11, and multiple second fire holes 21 correspond to a single first fire hole 11.

[0050] When the fire cover is in the low fire state, the gas burns through the relatively large number of second fire holes 21 with relatively small diameters. The flowing gas generates a flame separation relative to the second fire hole 21, and gathers to burn at the first fire hole 11 with higher fire hole strength, so that the flames of multiple second fire holes 21 converge into one first fire hole 11, The firepower of the flame of the ...

Embodiment 2

[0069] Figure 7 Shown is Embodiment 2 of the fire cap of the present invention. Most of the structure of the fire cover of embodiment 2 is the same as that of embodiment 1, except that: the edge of the second cover plate 2 forms a recessed notch 24, and the notch 24 is arranged near the ignition pin (not shown in the figure) of the burner . By setting the gap 24 near the ignition needle, the air can enter the region where the ignition needle is located through the gap 24, so that the air flow near the ignition needle is better and the ignition efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com