Projection lens optical system

An optical system and projection lens technology, applied in the field of projection lens optical system, can solve the problems of high abrasive cost of aspherical lenses, affecting image quality, poor temperature stability, etc., and achieve excellent optical characteristics, improve imaging quality, and good consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

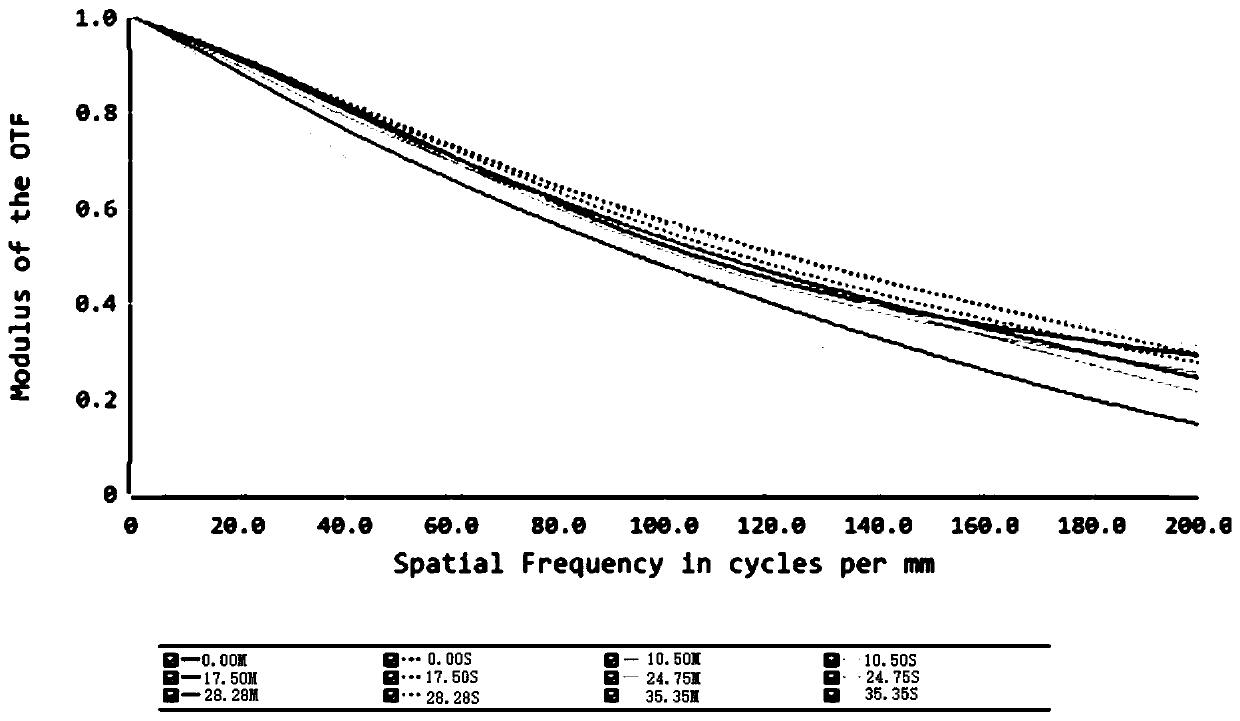

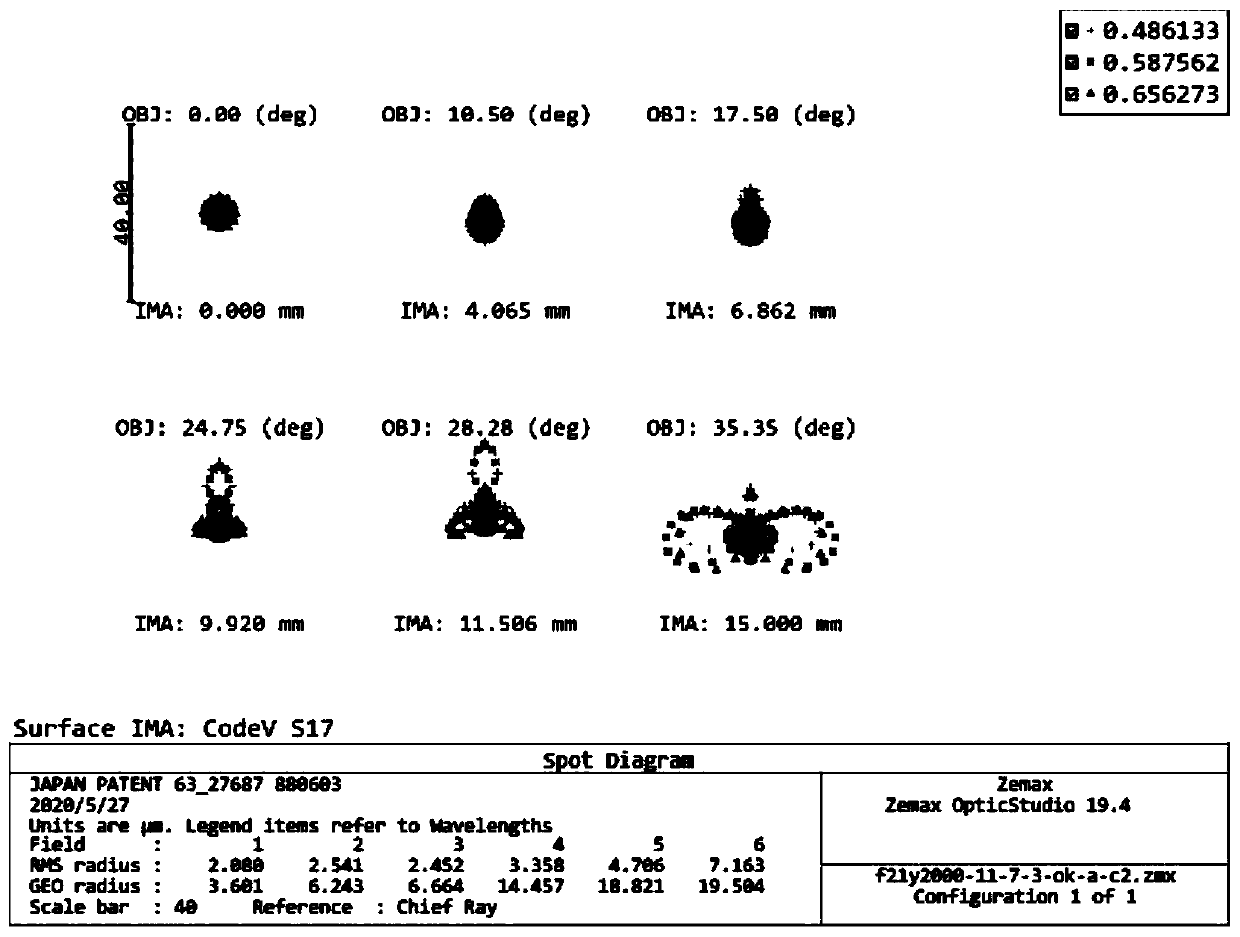

[0069] A projection lens optical system with a field angle of 70° belongs to a standard wide-angle lens. Through reasonable optical power distribution and material matching, various aberrations are compensated and corrected each other, so that when TV distortion is less than 2%, it still has high resolution and relative illuminance, thereby improving the quality of perception. The specific solutions are as follows:

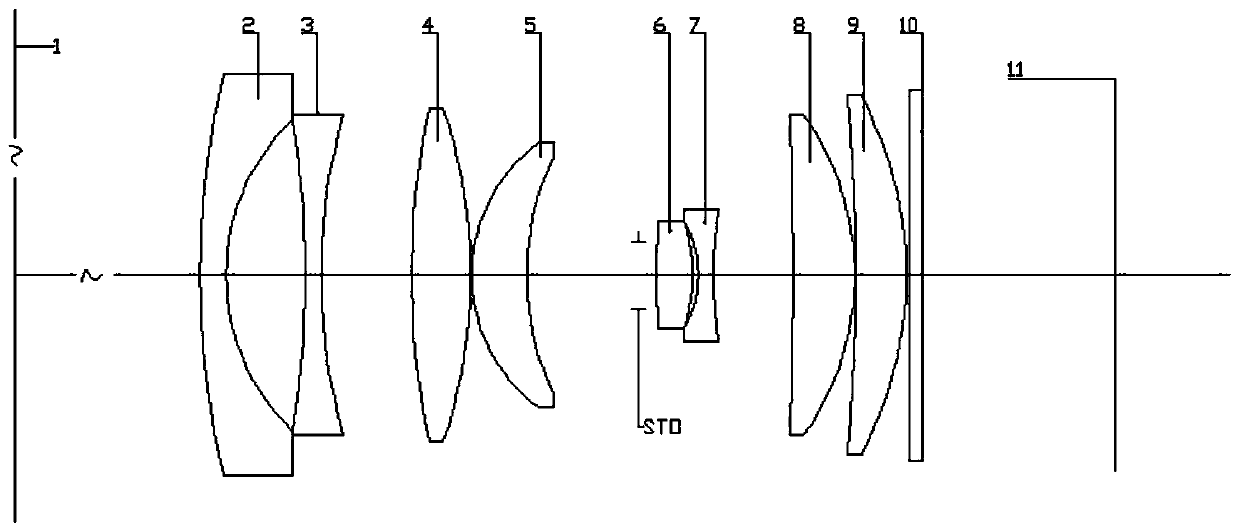

[0070] like figure 1 As shown, the optical system of the projection lens includes: wall 1, first lens 2, second lens 3, third lens 4, fifth lens 6, sixth lens 1, first lens 2, second lens 3, third lens 4, fifth lens 6, sixth The lens 7 , the seventh lens 8 , the eighth lens 9 , the protection panel 10 and the imaging target surface 11 . Preferably, the protective panel 10 is a protective lens made of glass with a thickness of 1 mm; the imaging target surface 11 is a slide; a diaphragm STO is provided between the fourth lens 5 and the fifth lens 6 .

[0071] For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com