Friction component of magnesium-aluminum alloy plate flattening and correcting device

一种镁铝合金、摩擦构件的技术,应用在合金加工领域,能够解决薄厚不均等问题,达到软化有效彻底、克服加热软化不均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0042] This embodiment is an embodiment of a flattening and straightening device for a magnesium-aluminum alloy plate.

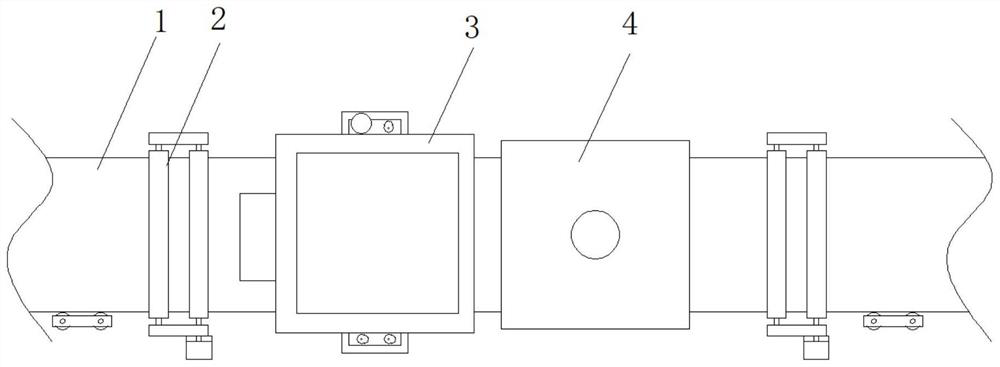

[0043] Such as figure 1 , 2 , 8, 9, 10, and 11, a magnesium-aluminum alloy plate flattening and straightening device disclosed in this embodiment includes a transmission member 2, a friction member 3, and a flattening member 4; the magnesium-aluminum alloy plate 1 can be Intermittent movement is carried out under the action of a plurality of transmission members 2, and friction members 3 and flattening members 4 are sequentially arranged along the moving direction of the magnesium-aluminum alloy plate 1, and the friction members 3 and flattening members 4 are symmetrically arranged on the magnesium-aluminum alloy plate 1. On both sides of the plate 1, and against the magnesium-aluminum alloy plate 1, the friction member 3 can adapt to the uneven surface of the magnesium-aluminum alloy plate 1, completely and thoroughly rub the uneven magnesium-aluminum allo...

specific Embodiment approach 2

[0049] This embodiment is an embodiment of a method for flattening and straightening a magnesium-aluminum alloy plate.

[0050] A method for flattening and straightening a magnesium-aluminum alloy plate disclosed in this embodiment includes the following steps:

[0051] Step a, parameter adjustment, according to the thickness of the magnesium-aluminum alloy plate 1 to be flattened and corrected, three parameters are set:

[0052] Parameter 1. The vibration time T of the exciter 3-10;

[0053] Parameter two, the rotational speed of pushing motor 4-9;

[0054] Parameter 3, the intermittent transmission interval of transmission member 2 is T1;

[0055] Step b, install the plate, pass one end of the strip-shaped magnesium-aluminum alloy plate 1 that needs to be flattened and corrected sequentially through the initial transmission member 2, the symmetrically arranged friction member 3, the symmetrically arranged flattened member 4 and the next transmission member 2, to complete ...

specific Embodiment approach 3

[0060] This embodiment is an embodiment of a friction member for flattening and correcting a magnesium-aluminum alloy plate.

[0061] It should be noted that the friction member for flattening and straightening of magnesium-aluminum alloy plates in this embodiment can be implemented alone, that is, as a part of a flattening and straightening device for magnesium-aluminum alloy plates, or it can be used in the embodiment A flattening and straightening device for a magnesium-aluminum alloy plate is further defined.

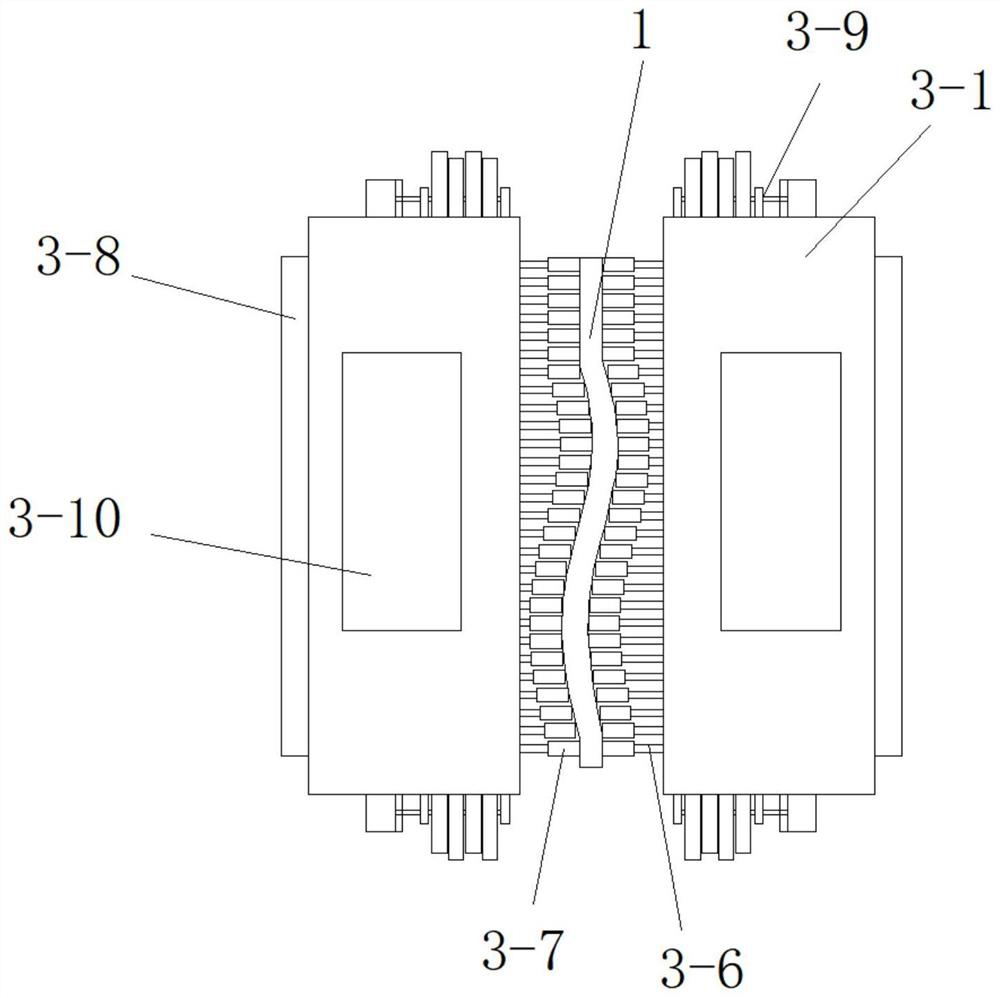

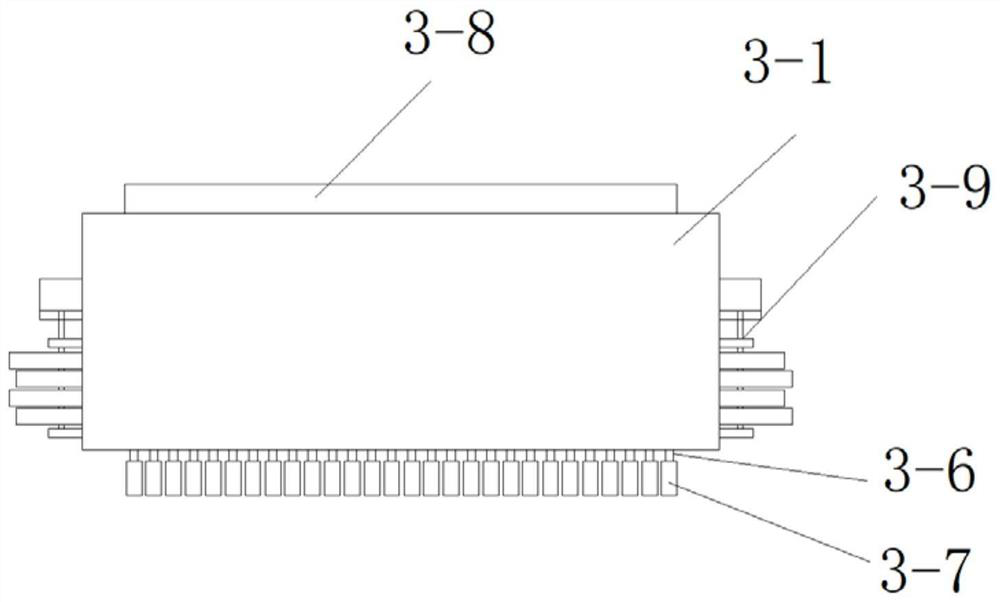

[0062] combine Figure 1-7 As shown, a friction member for flattening and correcting magnesium-aluminum alloy plates disclosed in this embodiment is characterized in that it includes a friction box 3-1, a limit plate 3-2, a splint 3-3, and a magnetic block 3-4 , positioning rod shaft 3-6, friction block 3-7, electromagnet disk 3-8, position adjustment group 3-9 and vibrator 3-10; the friction box 3-1 is provided with a limiting plate 3-2 , the friction box 3-1 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com