CVD (Chemical Vapor Deposition) workbench rotating device and CVD device

A technology of rotating device and workbench, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., and can solve the problems of inconsistent coating thickness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

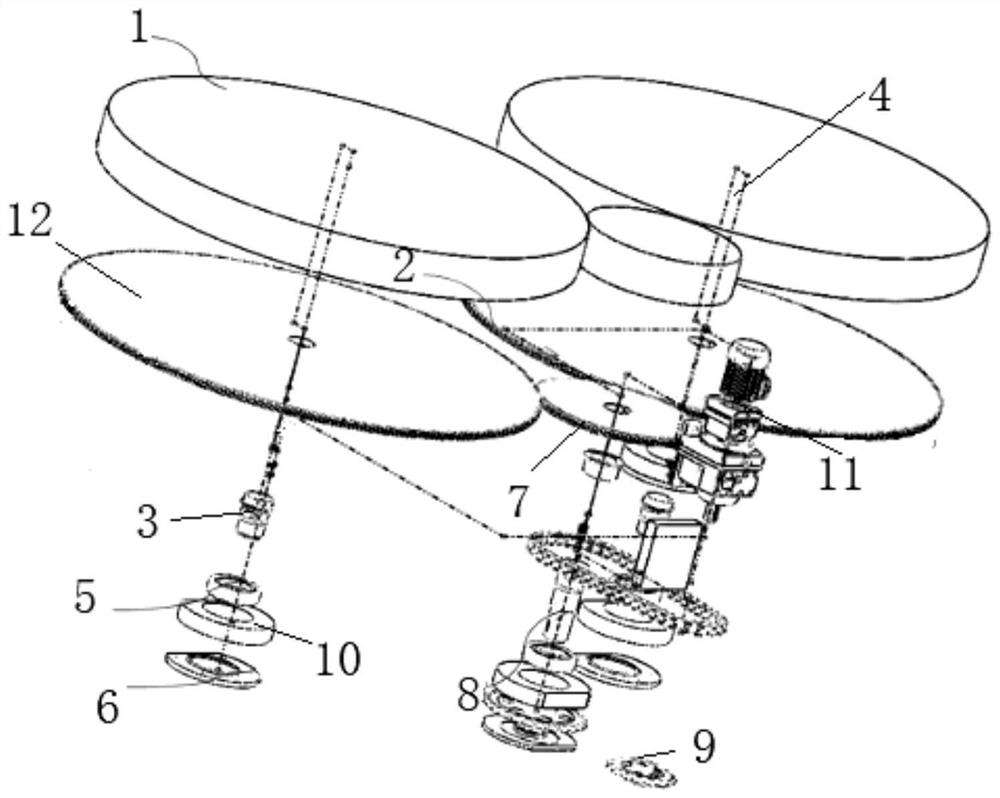

[0070] The embodiment of the present invention provides a CVD table rotating device, such as figure 1 shown, including:

[0071] The active rotating table 2 is rotatably connected to the furnace body through the main drive shaft 4; the above-mentioned active rotating table 2 is designed according to different furnace bodies. Optionally, for different product parts, it is also possible to change the installation position of the rotary table, for example, when facing long strips, the table can be installed on both sides of the furnace body to make two worktables work. The synchronous rotation of the table is used together to achieve the purpose of uniform coating on both sides of the workpiece at one time. Optionally, the whole rotary table can be raised and lowered by adding a screw nut.

[0072] One end of the sprocket drive shaft 8 extends into the furnace body and is connected to the main drive shaft 4, and the other end of the sprocket drive shaft 8 is located outside the ...

Embodiment 2

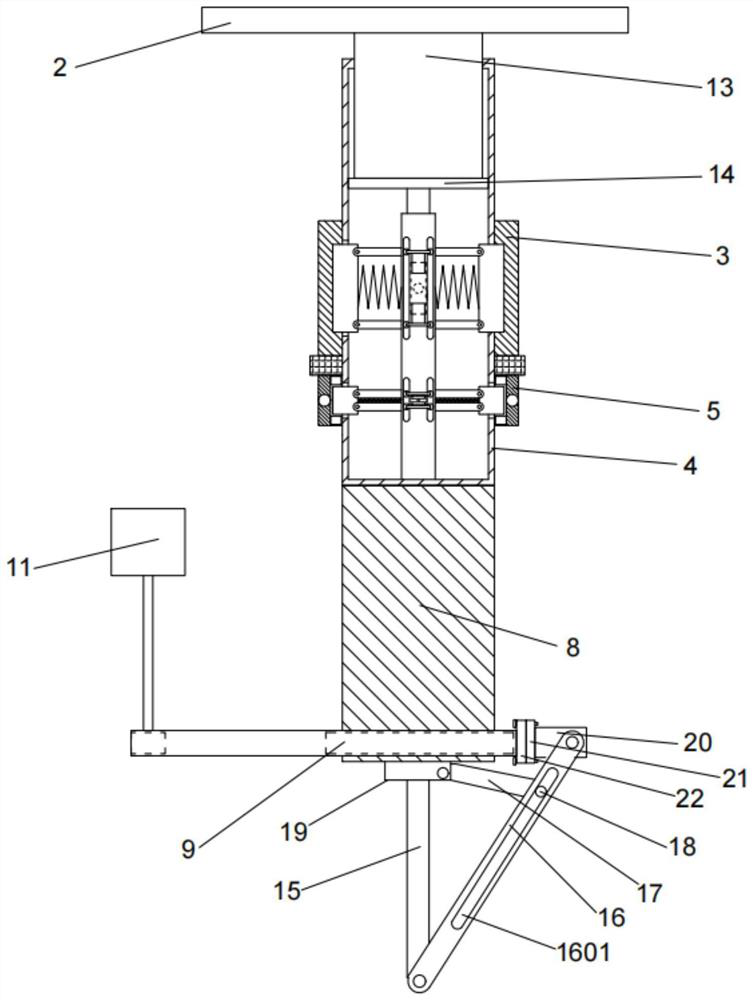

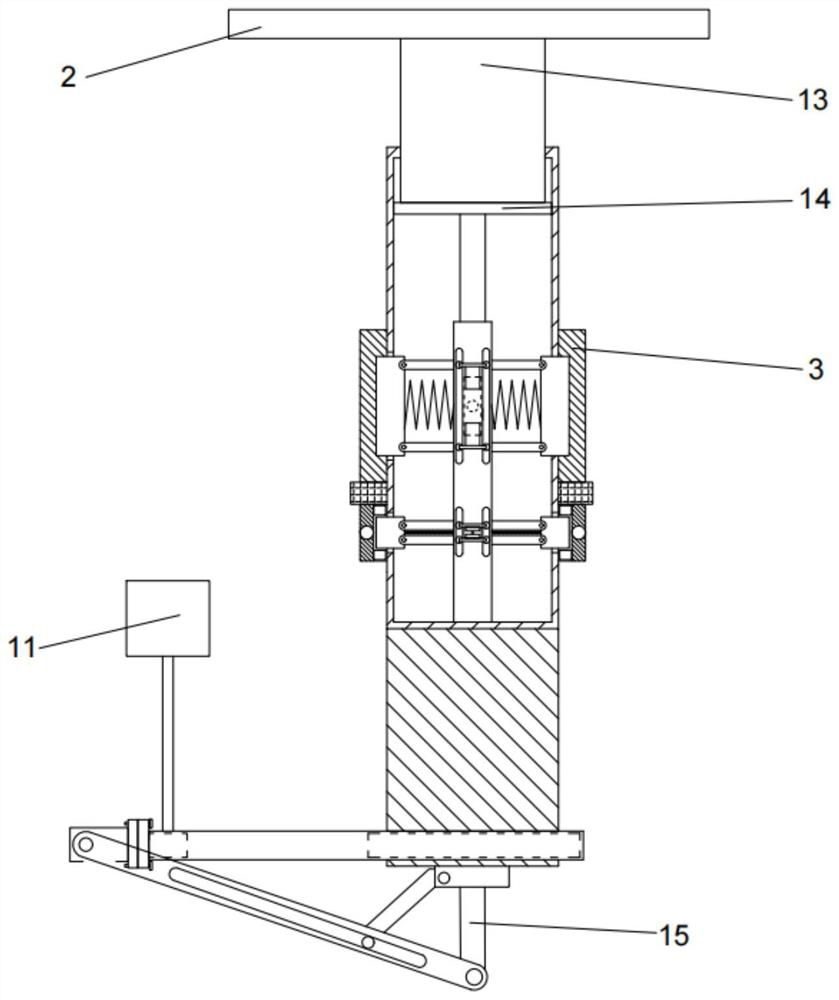

[0094] On the basis of Example 1, as figure 2 As shown in -5, the main drive shaft 4 is provided with an auxiliary mechanism, and the auxiliary mechanism includes:

[0095] Working cavity 401, the working cavity 401 is arranged inside the main drive shaft 4, the left and right ends of the working cavity 401 are symmetrically provided with a connecting hole 402, a connecting hole 2 403, and the connecting hole 2 403 and the connecting hole The first 402 is distributed up and down, and the working chamber 401 communicates with the outside world through the first connecting hole 402 and the second connecting hole 403;

[0096] The fixing block 23, the fixing block 23 is fixedly arranged in the middle of the lower end of the working chamber 401, the upper and lower sides of the fixing block 23 are respectively provided with a connecting assembly, the connecting assembly includes two chute-1 2301, the Two sliding grooves 1 2301 are symmetrically arranged on the left and right sid...

Embodiment 3

[0105] On the basis of embodiment 1 or 2, also include:

[0106] The gear sleeves inlaid on the outside of the active rotary table 2 and the driven rotary table 12 are exactly the same;

[0107] Load cell 1: A weighing layer is set on the upper end of the driven rotary table 12, and a weighing cell 1 is arranged inside the weighing layer, and the weighing sensor 1 is used to detect the upper end of the driven rotary table 12. the total weight of the connector;

[0108] Two weighing sensors: a weighing layer is arranged on the upper end of the active rotating table 2, and a second weighing sensor is arranged inside the weighing layer, and the second weighing sensor is used to detect the connection of the upper end of the active rotating table 2 the total weight of the piece;

[0109] Distance sensor 1: The distance sensor is arranged at the center of the upper end of the driven rotary table 12, and is used to detect the distance between the connecting piece on the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com