Improved device for producing zinc selenide by PVD method and production method

A technology of zinc selenide and tube cover, which is applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of high cost, long cycle of zinc selenide, flammable gas, etc., to solve the problem of inconsistent thickness and improve Material utilization rate, the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

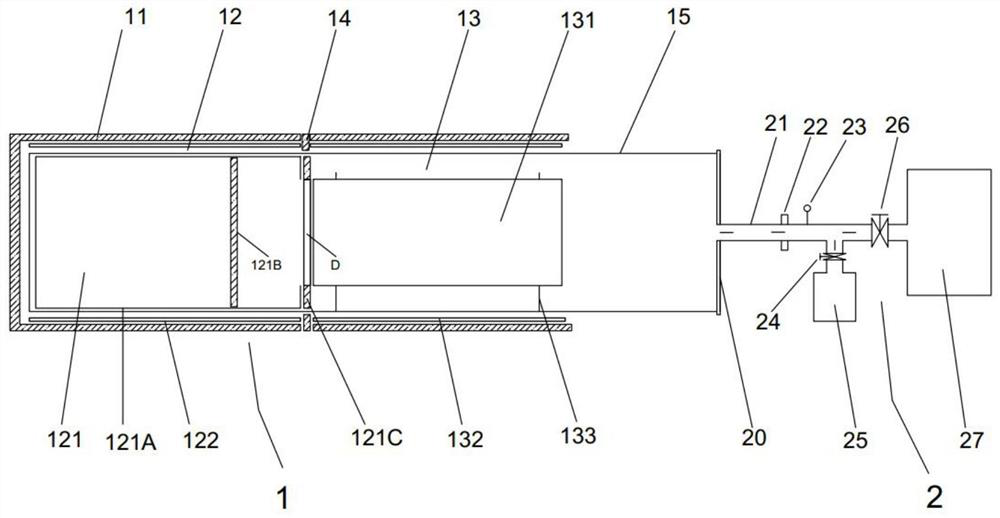

[0045] Such as figure 1 As shown, an improved device for producing zinc selenide by PVD method, including evaporation deposition system 1 and vacuum system 2;

[0046] The evaporative deposition system 1 includes a thermal insulation shell 11 and a quartz tube cover 15;

[0047] The inner side of the thermal insulation shell 11 is divided into an evaporation zone 12 and a deposition zone 13 along the axial direction;

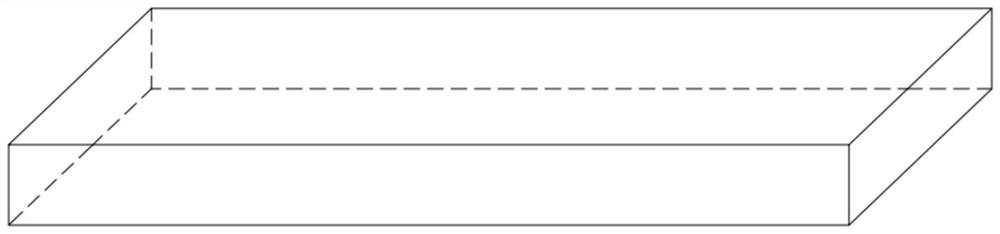

[0048] The quartz tube cover 15 is located inside the thermal insulation shell 11, and the inside of the quartz tube cover 15 located in the evaporation area 12 is provided with a material holding assembly 121. 121B divides the inner side of the material bottle 121A into two cavities, the inner cavity and the outer cavity respectively. The end of the outer cavity is provided with an opening, and the opening faces the deposition area 13. The setting of the filter pad 121B can reduce the evaporation and sublimation of the material bottle 121A. Dust and other imp...

Embodiment 2

[0051] On the basis of Embodiment 1, the following improvements are further made: the crucible 121A is a quartz glass bottle, and the filter pad 121B is made of ceramic fiber cotton. 2. The guide pipe 21 in the vacuum system 2 includes a three-way joint, one end of the three-way joint is connected to the vacuum gauge 23 , one end is connected to the pre-pumping valve 24 , and the other end is connected to the main pumping valve 26 . That is, a three-way interface is used to connect the pre-pump valve 24 and the main pump valve 26 after the vacuum gauge 23 .

Embodiment 3

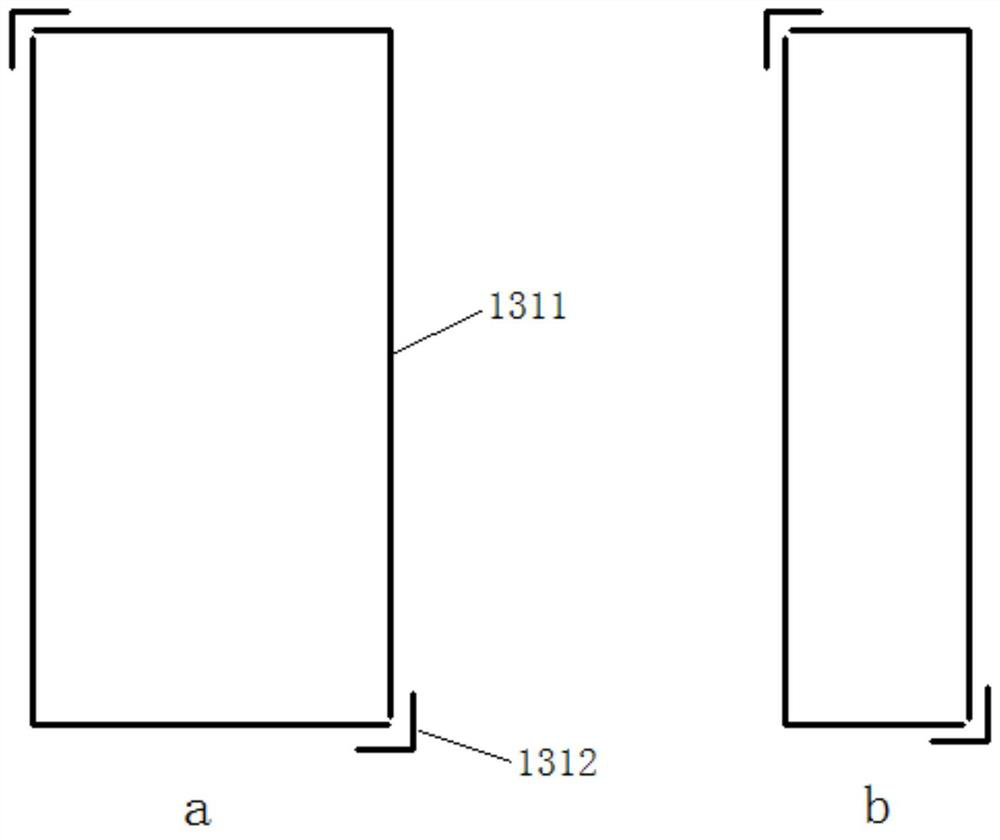

[0053] On the basis of Embodiment 2, the following improvements are further made: the deposition mold 131 is positioned in the quartz tube cover 15 through the positioning clip 133 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com