Vibration signal calibration method, storage medium and electronic equipment

A vibration signal and calibration method technology, which is applied in the manufacture of motor generators, electric components, electromechanical devices, etc., can solve problems affecting tactile feedback and inconsistency of vibration feedback, and achieve the effect of enhancing tactile feedback and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

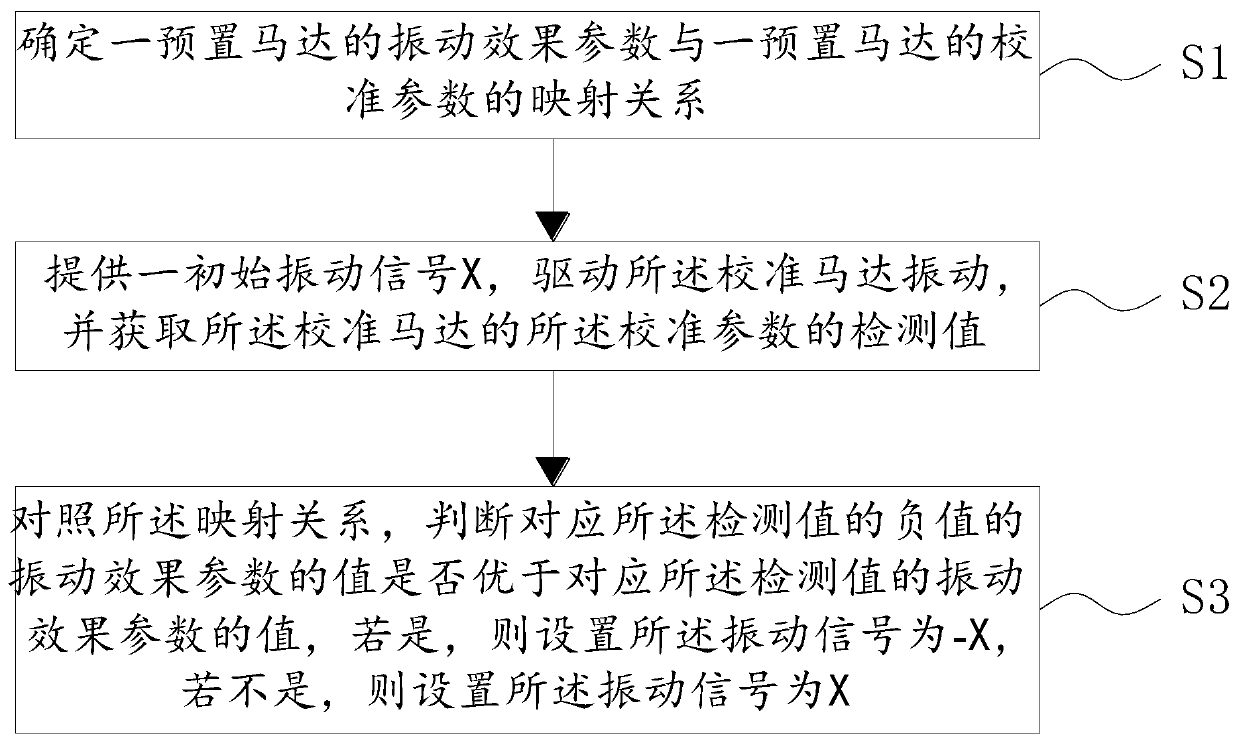

[0034] A method for calibrating a vibration signal proposed in this embodiment, the vibration signal is used to drive a calibration motor to vibrate, please refer to figure 1 , the adjustment method of the vibration signal includes:

[0035] S1. Determine a mapping relationship between a vibration effect parameter of a preset motor and a calibration parameter of a preset motor.

[0036] Specifically, the mapping relationship between the vibration effect parameters and the calibration parameters needs to be determined before subsequent calibration operations can be performed. Each parameter in the above step S1 is explained as follows:

[0037] The preset motor is a virtual motor model, which can be used to simulate an actual motor in some scenarios.

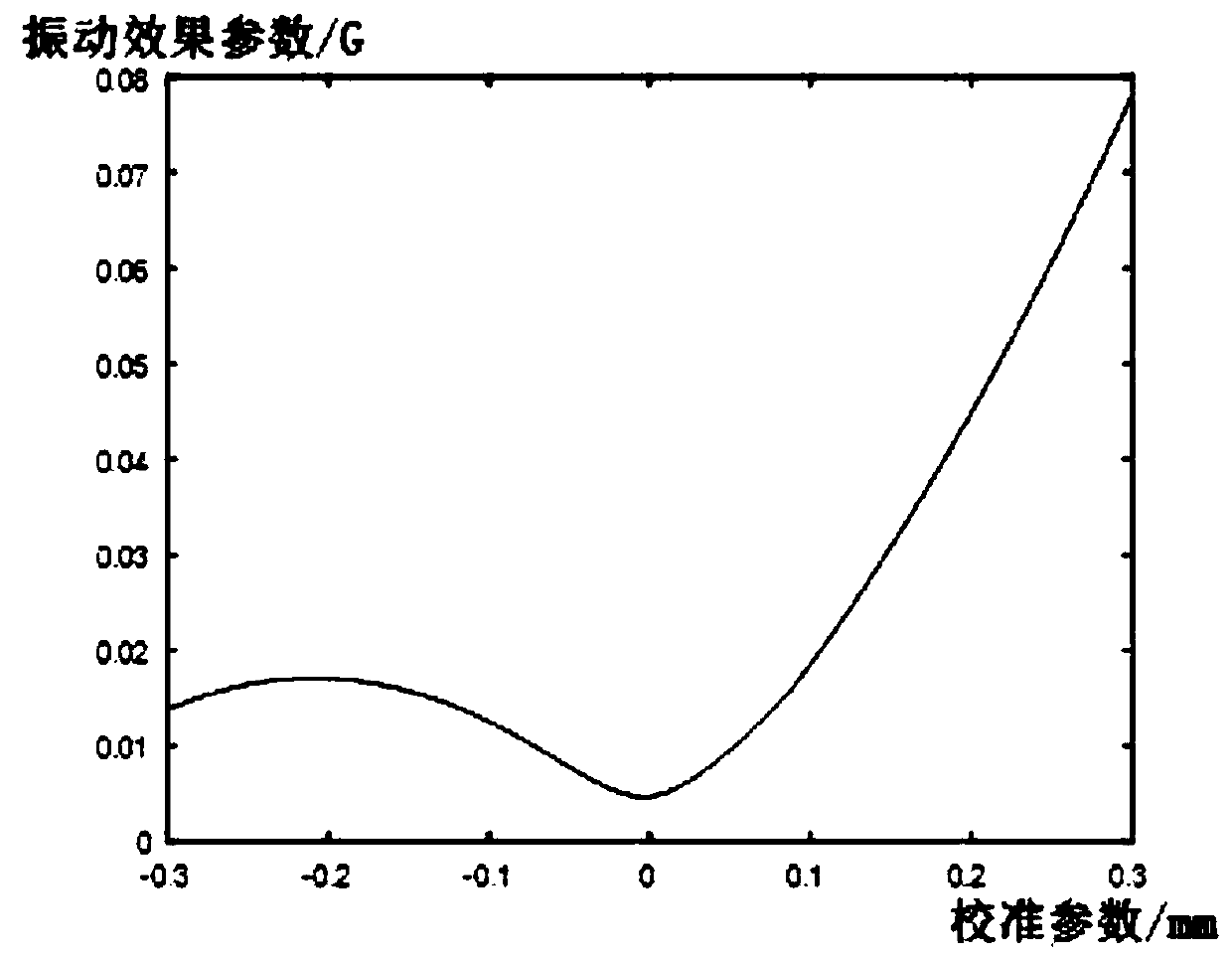

[0038] The vibration effect parameter is a parameter that reflects the vibration effect of the motor. More specifically, the vibration effect parameter is a parameter reflecting the vibration braking effect of the motor.

[0...

Embodiment 2

[0057] The computer-readable storage medium provided by this embodiment, the computer-readable storage medium stores a vibration signal calibration program, and when the vibration signal calibration program is run by a processor, the calibration of the vibration signal described in the above-mentioned embodiment 1 is performed method steps. For specific implementation, reference may be made to Method Embodiment 1, which will not be repeated here.

[0058] Also, see Image 6 , the present embodiment also provides an electronic device, the electronic device includes a processor 21, a memory 22 and a calibration program 23 for vibration signals, Image 6 Only some components of the electronic device are shown.

[0059] The storage 22 may be an internal storage unit of the electronic device in some embodiments, such as a hard disk or memory of the electronic device. The memory 22 may also be an external storage device of the electronic device in other embodiments, such as a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com