A non-contact cut pile fabric thickness photographing device

A fabric thickness, non-contact technology, used in textiles and papermaking, textile material inspection, TV and other directions, can solve the problems of low efficiency and high cost, achieve low price, simple structure, and achieve the effect of shooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

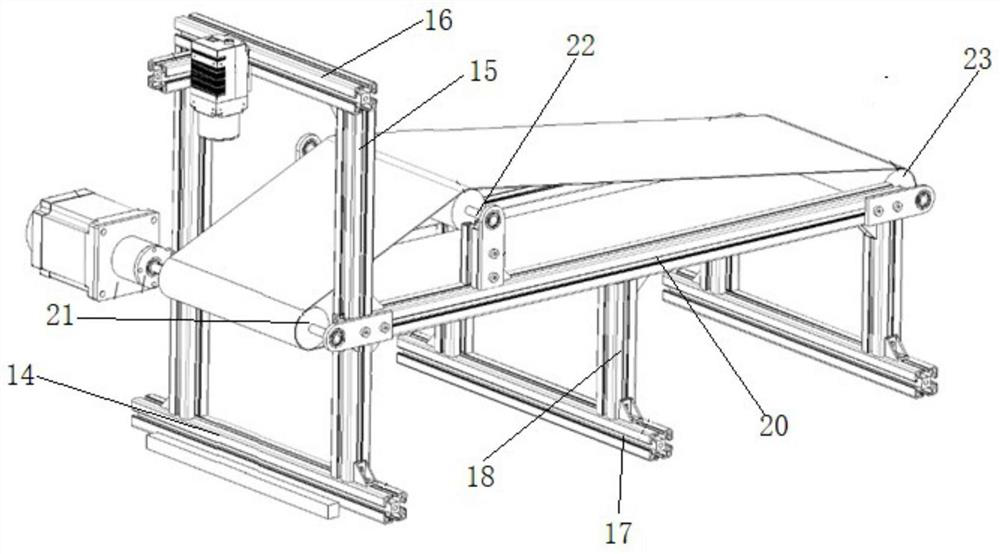

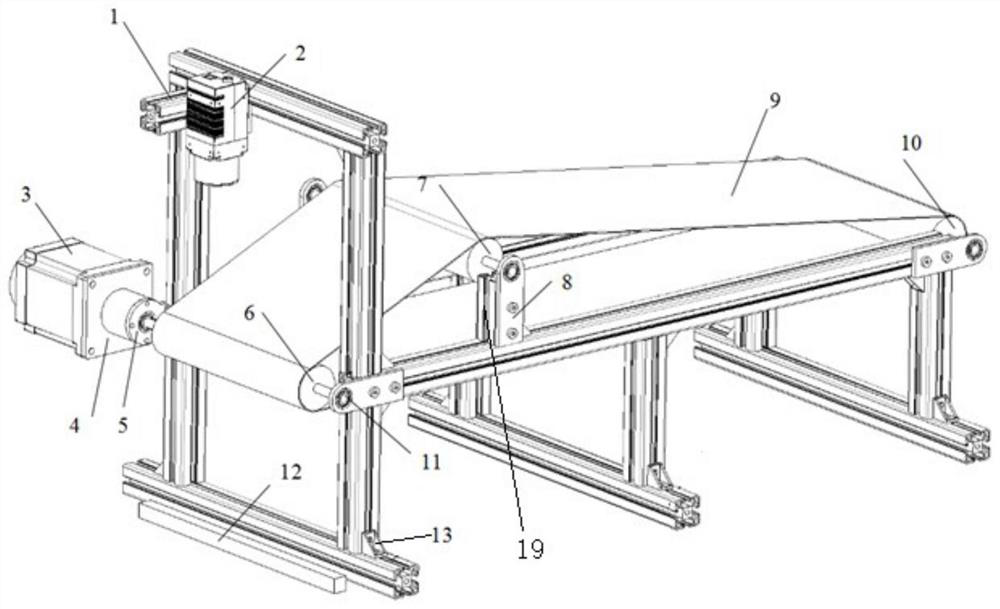

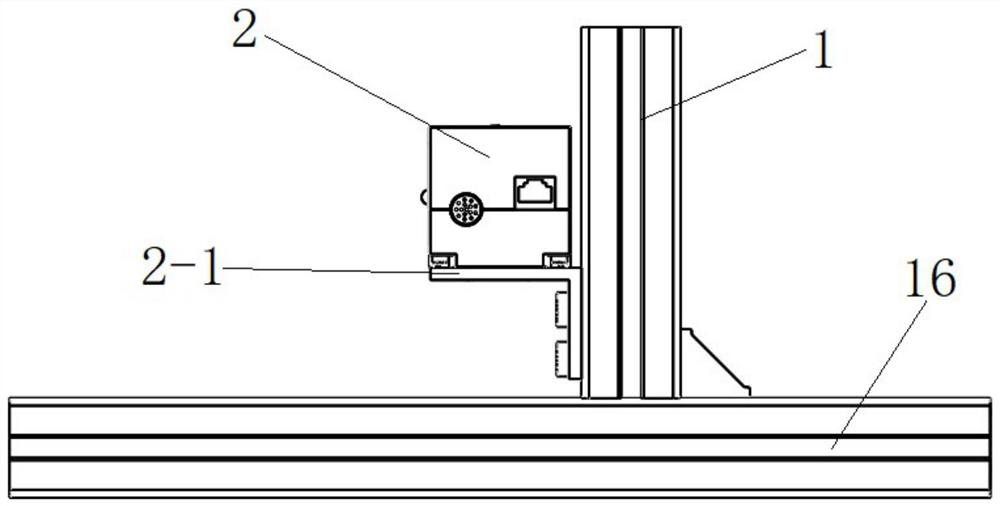

[0030] A non-contact cut pile fabric thickness photographing device, the structure is as follows figure 1 As shown, it includes a support a14 and several supports b17. The support a14 is connected with two long supports 15, and a horizontal support 16 is fixedly connected between the two long supports 15, and the horizontal support 16 is connected with the cloud platform 1. Seat b17 is fixedly connected with two short supports 18, and long support 15 is fixedly connected with conveyor belt support 20, and conveyor belt support 20 is fixedly connected with short supports 18, as figure 2 As shown, an industrial camera 2 is connected to the platform 1 to obtain tangential images of the cut pile fabric.

[0031] A drive roller mechanism 21 is fixedly connected between the two long supports 15, the drive roller mechanism 21 is connected to a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com