Method for producing a brake disc, and brake disc

A technology of brake discs and braking surfaces, applied in the direction of brake discs, brake parts, brake types, etc., can solve the problems of not being painted, not easy to coat, etc., and achieve simple cost, simple methods and methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

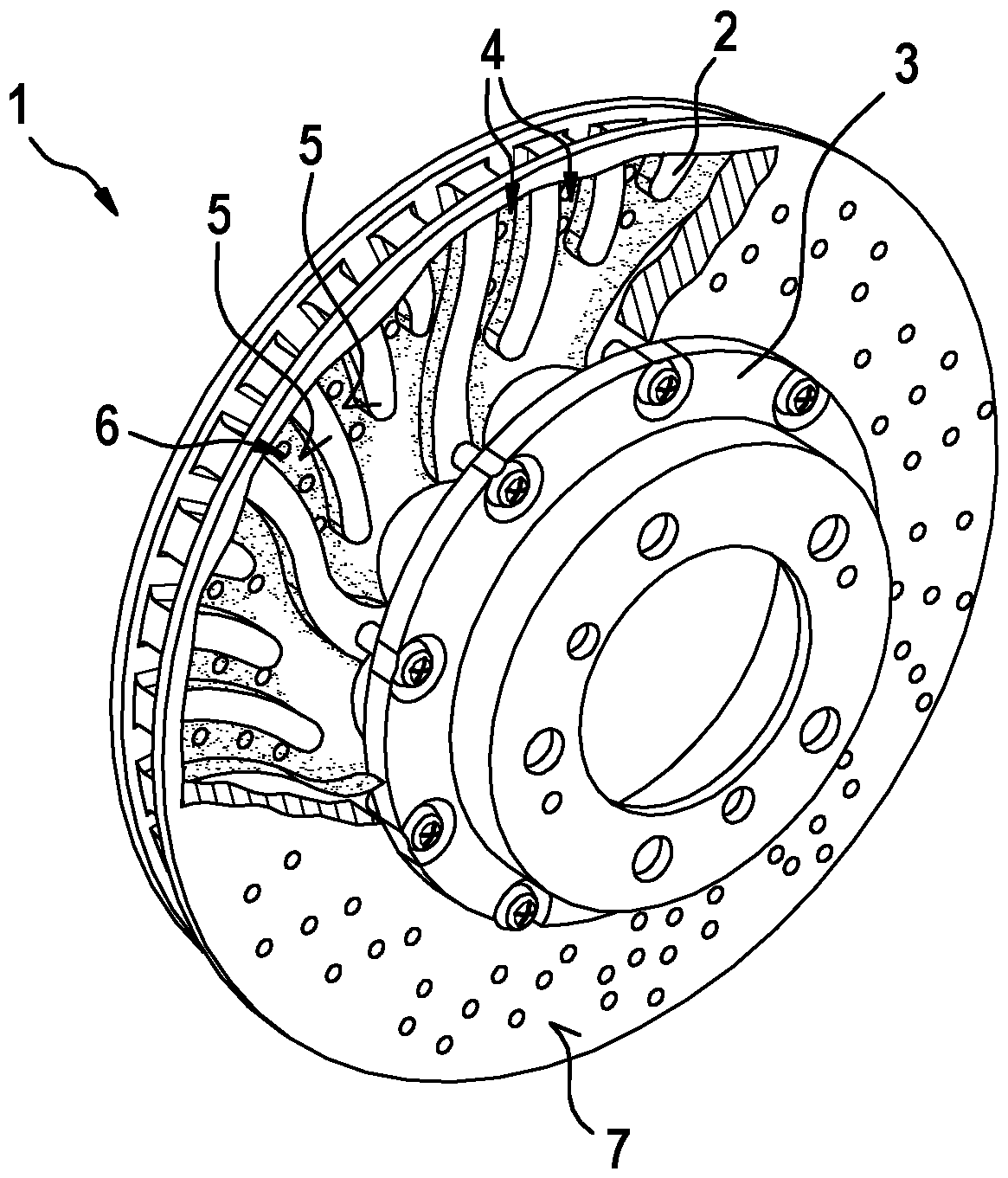

[0013] figure 1 An advantageous brake disk 1 is shown in a simplified partial perspective sectional illustration. The brake disk 1 has a circular base disk 2 to which a brake disk drum 3 is fastened, which can alternatively also be formed in one piece with the base disk 2 .

[0014] The base disc 2 has a plurality of integrated cooling channels 4 which extend from the inner circumference of the brake disc 2 to the outer circumference. In this case, the cooling channel 4 runs essentially deviated from the radial extent, in particular curved from the inside to the outside. Furthermore, adjacent cooling channels 4 are configured differently here.

[0015] The base plate 2 here is made of cast iron or aluminum, possibly with a wear-resistant layer, and has a coating 6 on the surface 5 of the cooling channels 4 in order to prevent corrosion, especially in the region of the cooling channels 4 . In particular, all surfaces of the brake disk 1 facing the cooling channels 4 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com