Long-acting corrosion prevention method for embedded prestressed cylinder concrete pipe

A technology of prestressed steel and concrete pipes, applied in the direction of anti-corrosion/anti-rust protection of pipelines, pipes, rigid pipes, etc., can solve the problems of inability to effectively protect prestressed steel wires, insufficient deformation and crack resistance of mortar, and insufficient congenital durability. , to achieve the effect of eliminating insufficient crack resistance, high crack self-healing performance, high deformation and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

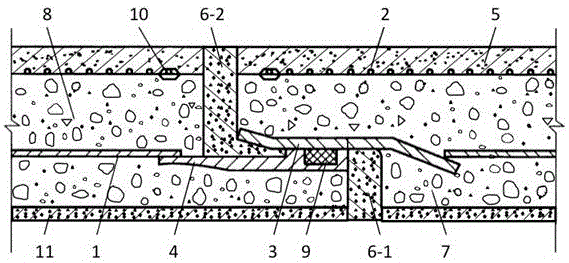

[0043] Embedded prestressed steel cylinder concrete pipe (PCCPE) prestressed steel wire, part of the socket steel ring and part of the socket steel ring factory-made ultra-high performance concrete outer protective layer 5 and inner concrete factory-made ultra-high performance concrete inner protective layer 11, Finished in the factory. After the pipeline is installed in place, the ultra-high-performance concrete inner protective layer 6-1 and outer protective layer 6-2 of the exposed parts of the socket steel ring and the socket steel ring at the joint are completed at the pipeline installation site. Specific steps are as follows:

[0044]1. Prepare cohesive ultra-high performance concrete in the factory: the slump of the freshly mixed mixture is 30~100mm, which is suitable for mechanical roller injection, spraying or troweling to make a protective layer. The hardening performance of ultra-high performance concrete (standard curing 28 days) should reach: the compressive stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com