External spring spray gun head with double check valve structure

A double-check valve, spring-type technology, applied in a single hand-held device, injection device, etc., can solve the problems of short service life, high failure rate, and many parts of the spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

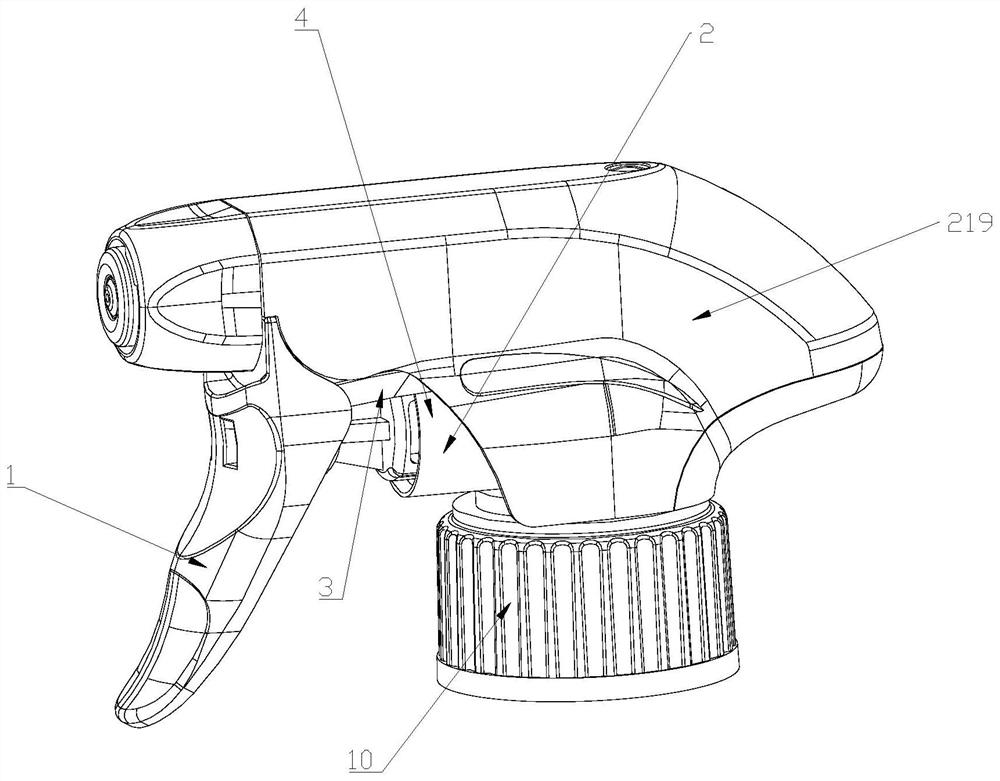

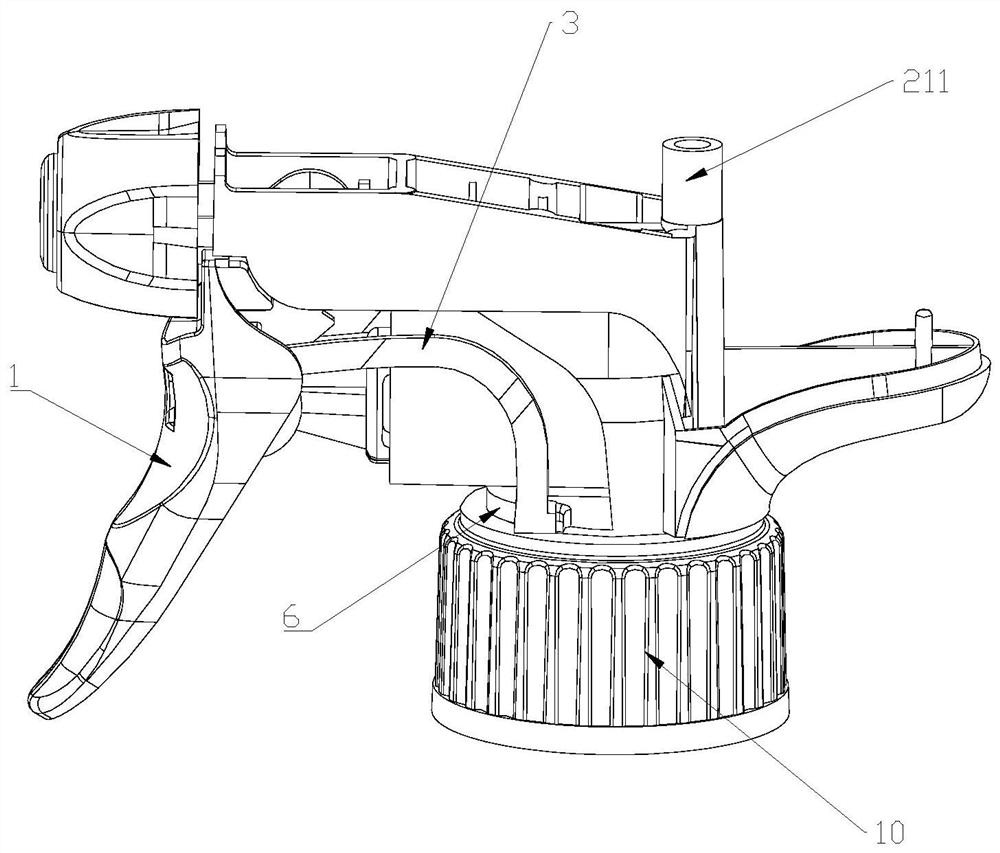

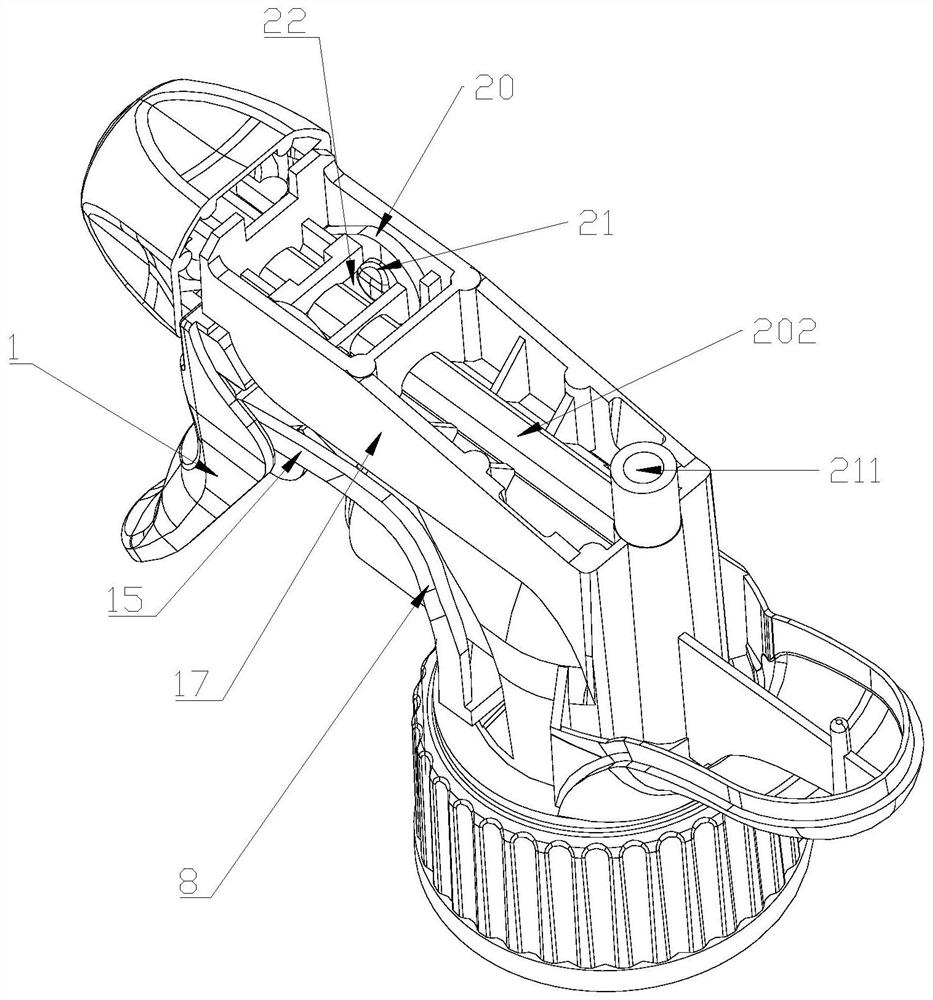

[0041] An external spring-type spray gun head with a double check valve structure, including a mounting seat 2, and a trigger 1 installed on the mounting seat 2, a spring member 3, a piston 100, a nozzle 300 and a cover body 10; There is a shell. The mounting base 2 includes a piston sleeve 4 for installing the piston 100; the piston 100 is sealed and installed in the piston sleeve 4, the trigger 1 is installed on the mounting base 2 and can rotate around the mounting base 2, and one end of the piston 100 is connected with the trigger 1, The trigger 1 drives the piston 100 to reciprocate, one end of the spring member 3 is installed on the mounting base 2 and the cover body 10, and the other end of the spring member 3 is installed on the trigger 1 to collect elastic potential energy to make the trigger 1 and the piston 100 return automatically The spring part 3 is a metal part, the mounting seat 2 is a plastic part or a metal part, the inner surface of the cover body 10 is prov...

Embodiment 2

[0062] Such as Figure 1 to Figure 5 As shown, the difference between the present embodiment and the first embodiment is that the limit snap ring 6 is fixedly connected with the cover body 10 or the limit seat 5 .

Embodiment 3

[0064] The difference between this embodiment and Embodiment 2 is that the limit snap ring 6 is fixedly connected with the cover body 10 or the limit seat 5 by glue. The connecting rib 103 is a reinforcement 108 integrally formed by four congruent right-angled trapezoidal plates, and the radial dimension of the connecting rib 103 toward the trigger 1 gradually decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com