Tool for reinforcing shells of frame-shaped investment castings

A precision casting and frame-type technology, which is applied in the field of tooling for frame-type precision casting shell reinforcement, can solve the problems of sand collapsing, inability to realize processing, and reduction of shell reinforcement force, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Hereinafter, various exemplary embodiments, features, and aspects of the present invention will be described in detail with reference to the accompanying drawings.

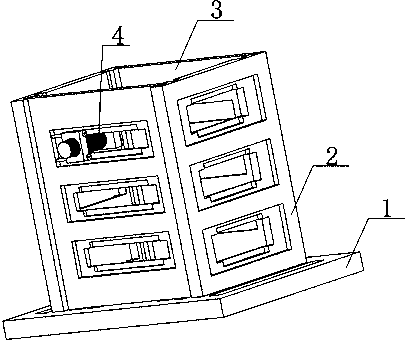

[0038] First, combine Figure 8~Figure 9 The structure of the device for reinforcing the shell of a frame type casting according to the present invention will be described.

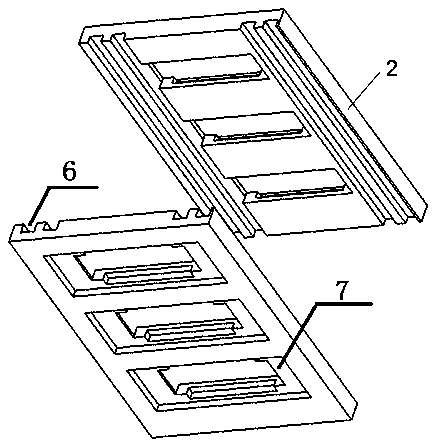

[0039] A tooling for strengthening the shell of a frame-type precision casting of the present invention: a base plate 1, a main plate 2 fixed on the base plate 1, a side plate 3 connected to the main plate 2, and targeted fasteners 4 for special-shaped parts of the casting. The reinforcement block 9 of the firmware 4 is pasted with asbestos felt at the end far away from the connecting rod 10. The reinforcement block 9 does not directly contact the casting, but contacts the casting after setting the asbestos felt on the surface of the reinforcement block 9 to tighten the adjustment spring. 11 is sleeved on the outside of the connecting...

Embodiment 2

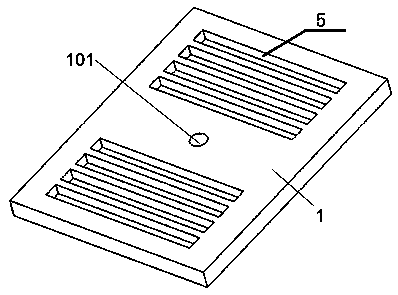

[0053] The following describes the assembly method of the device for shell reinforcement according to the present invention, which can realize quick installation, in combination with the above-mentioned tooling for shell reinforcement of frame-type precision castings, for the convenience of being applied to small-sized frame castings. Firstly, the casting is tightly wound with a high temperature resistant material, such as asbestos felt, and placed on the bottom plate 1, and the position of the gate is aligned with the through hole 101 on the bottom plate 1. The main board 2 is plugged into the innermost side of the base plate 1 through the installation groove I5 on the base plate 1 , and the installation groove I5 is in the shape of a dovetail groove. The rest of the installation groove I5 on the bottom plate 1 can be filled with T-shaped blocks that completely match the shape of the installation groove I5, or it can not be filled. The side plate 3 passes through the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com