Fluid pressure rotating device and construction machine

A rotating device and fluid pressure technology, which is applied in the direction of liquid variable capacity machinery, construction, mechanical equipment, etc., can solve the problems of increased friction, reduced volumetric efficiency of fluid motors, and reduced mechanical efficiency of fluid motors, etc., to achieve the best preventive performance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

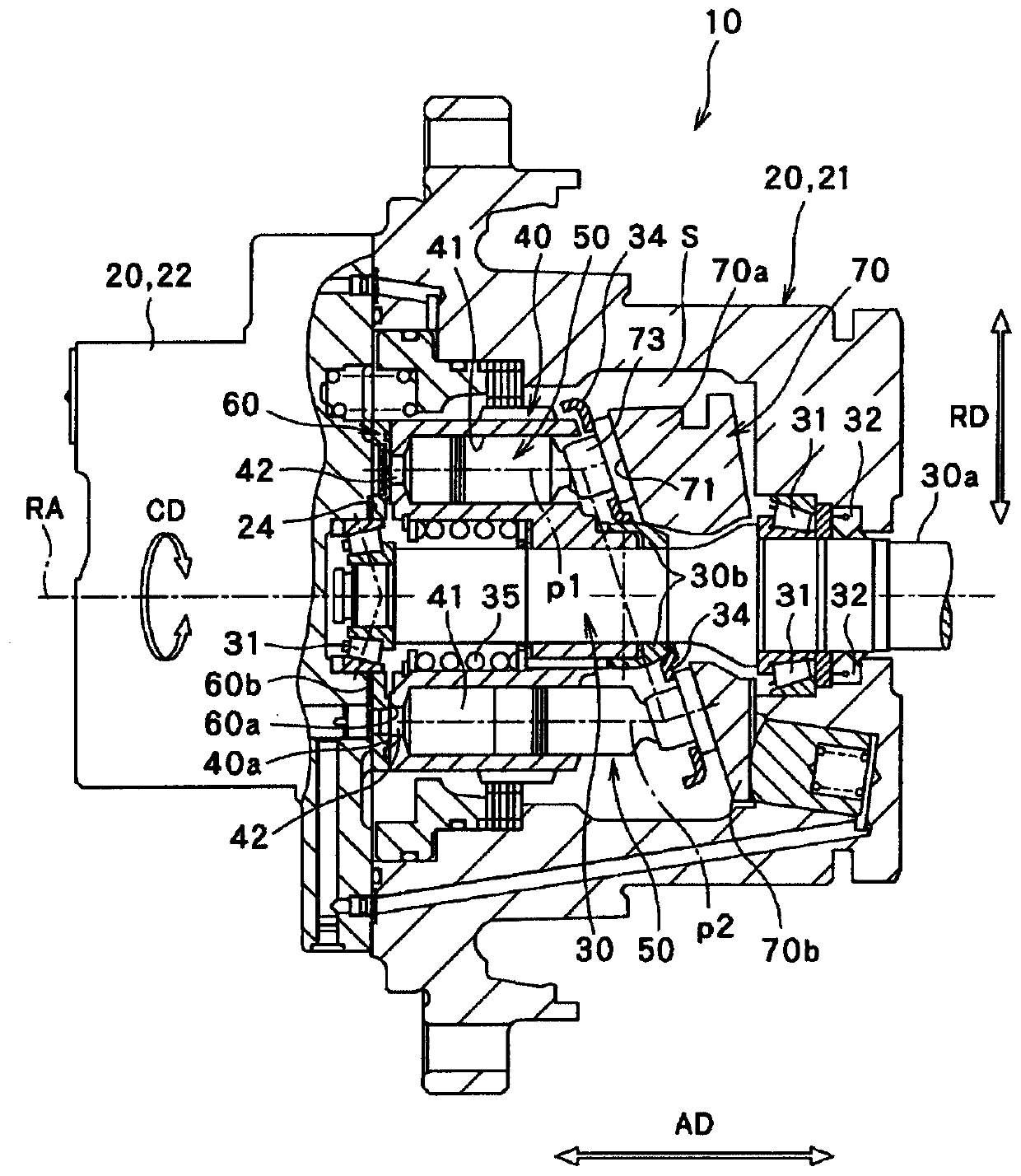

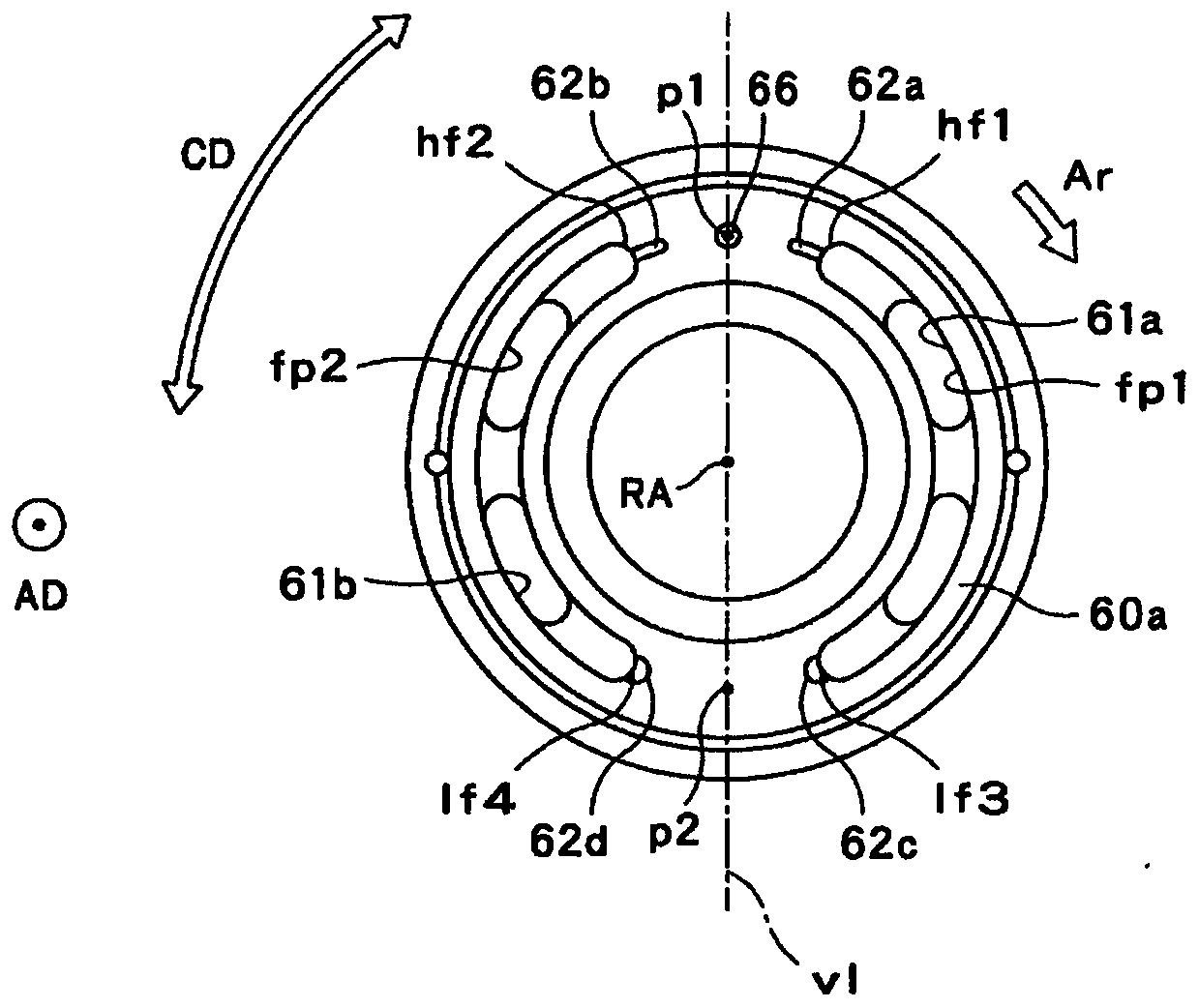

[0027] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. In addition, for the sake of easy understanding, the elements shown in each drawing may include elements shown differently from actual ones such as dimensions and scales.

[0028] The fluid pressure rotation device 10 described below functions as an axial piston type device. In the illustrated example, the fluid pressure rotation device 10 is configured as a fluid motor, and outputs rotation by supplying fluid. More specifically, the illustrated fluid motor 10 is configured as a swash plate type fluid motor.

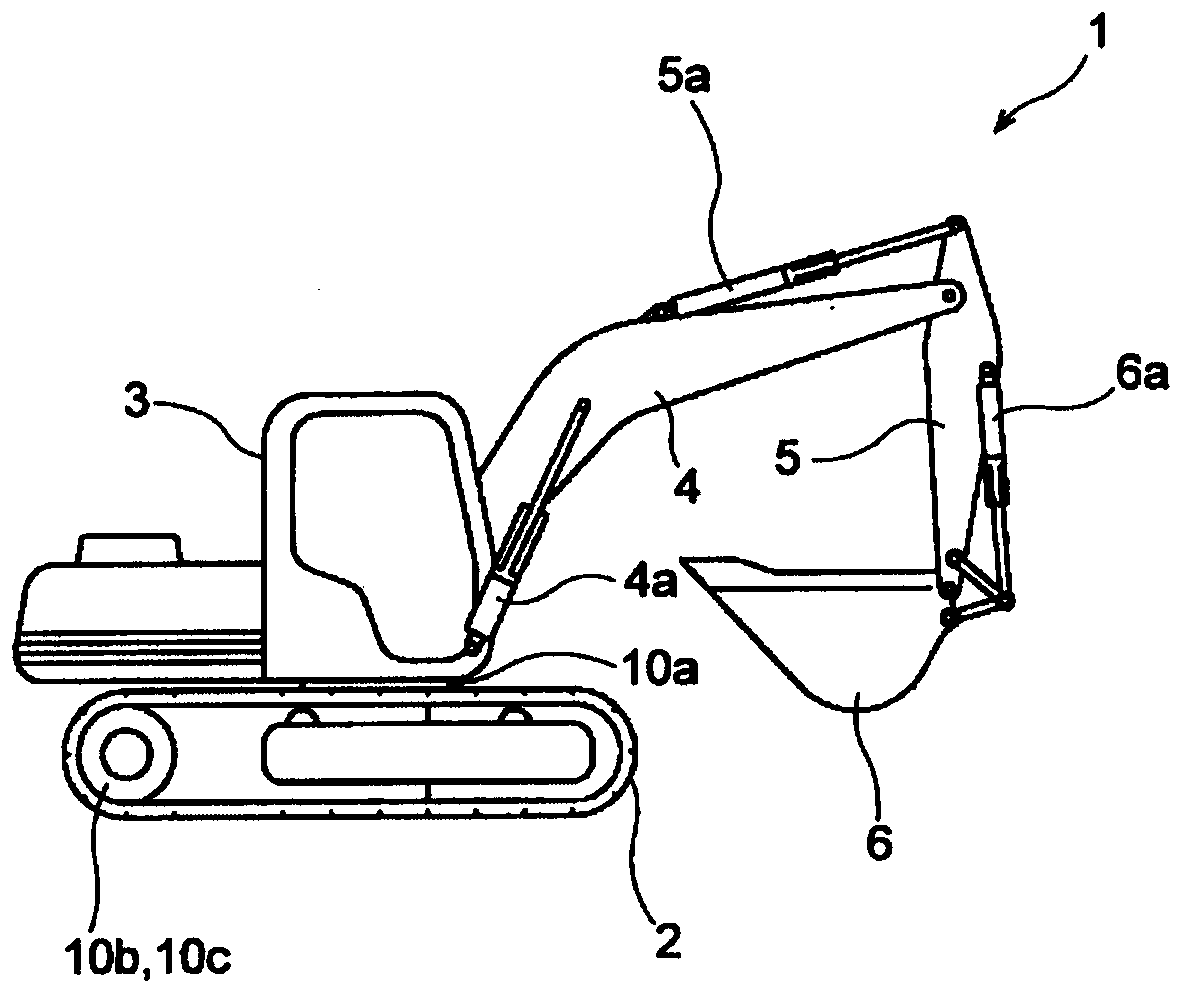

[0029] In addition, below, the case where the fluid motor 10 is used as the motor for the turning device 10a of the hydraulic excavator 1 or the traveling devices 10b and 10c will be described.

[0030] First, the hydraulic excavator 1 will be described. figure 1 It is an external view showing a schematic configuration example of the hydraulic excavator 1 . I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap