Double-reed type jack structure and connector

A double reed and hole structure technology, which is applied in the direction of connection, parts of connection devices, metal/alloy conductors, etc., can solve the problems of insufficient contact holding force and current carrying capacity, and a small number of contacts, and achieve stable contact holding force The effect of good properties, high quantity, good elasticity and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

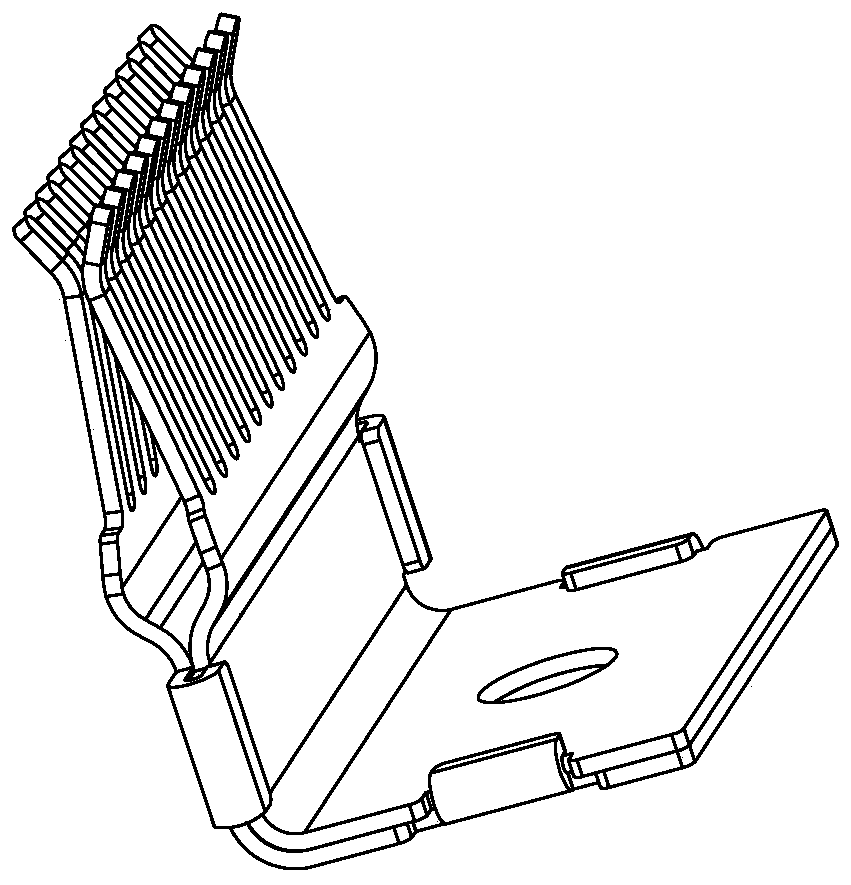

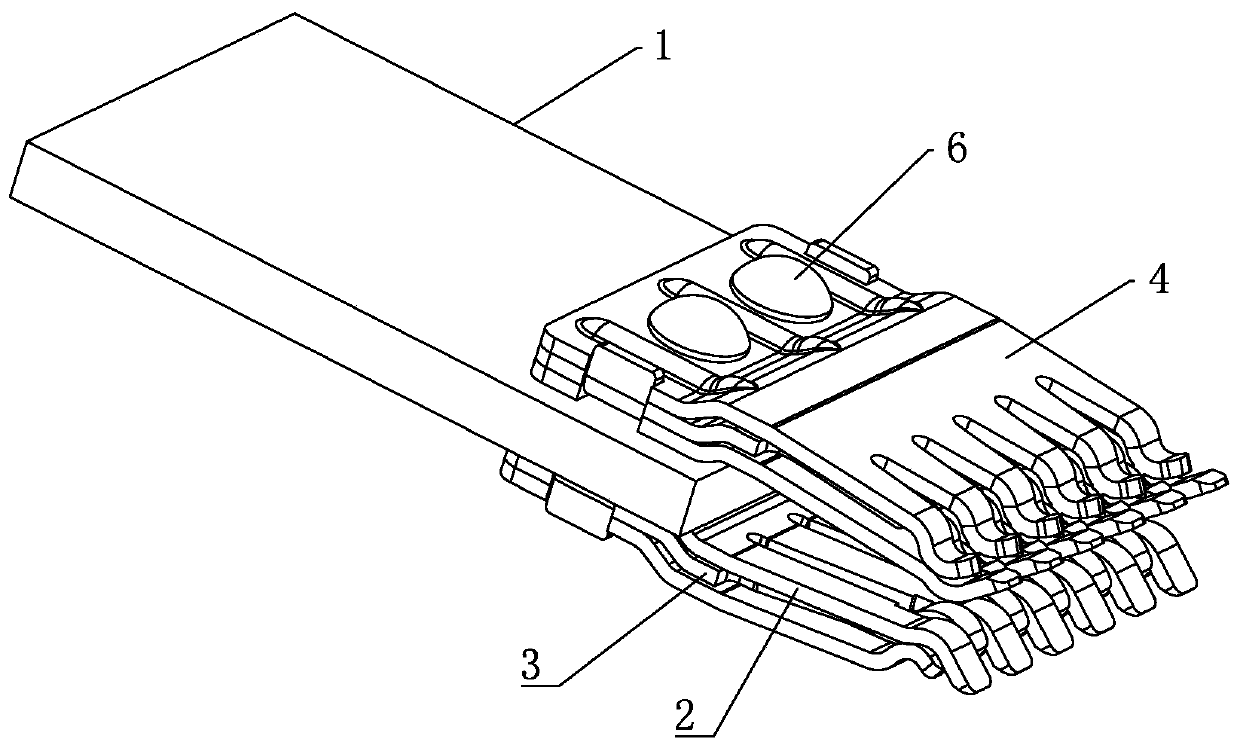

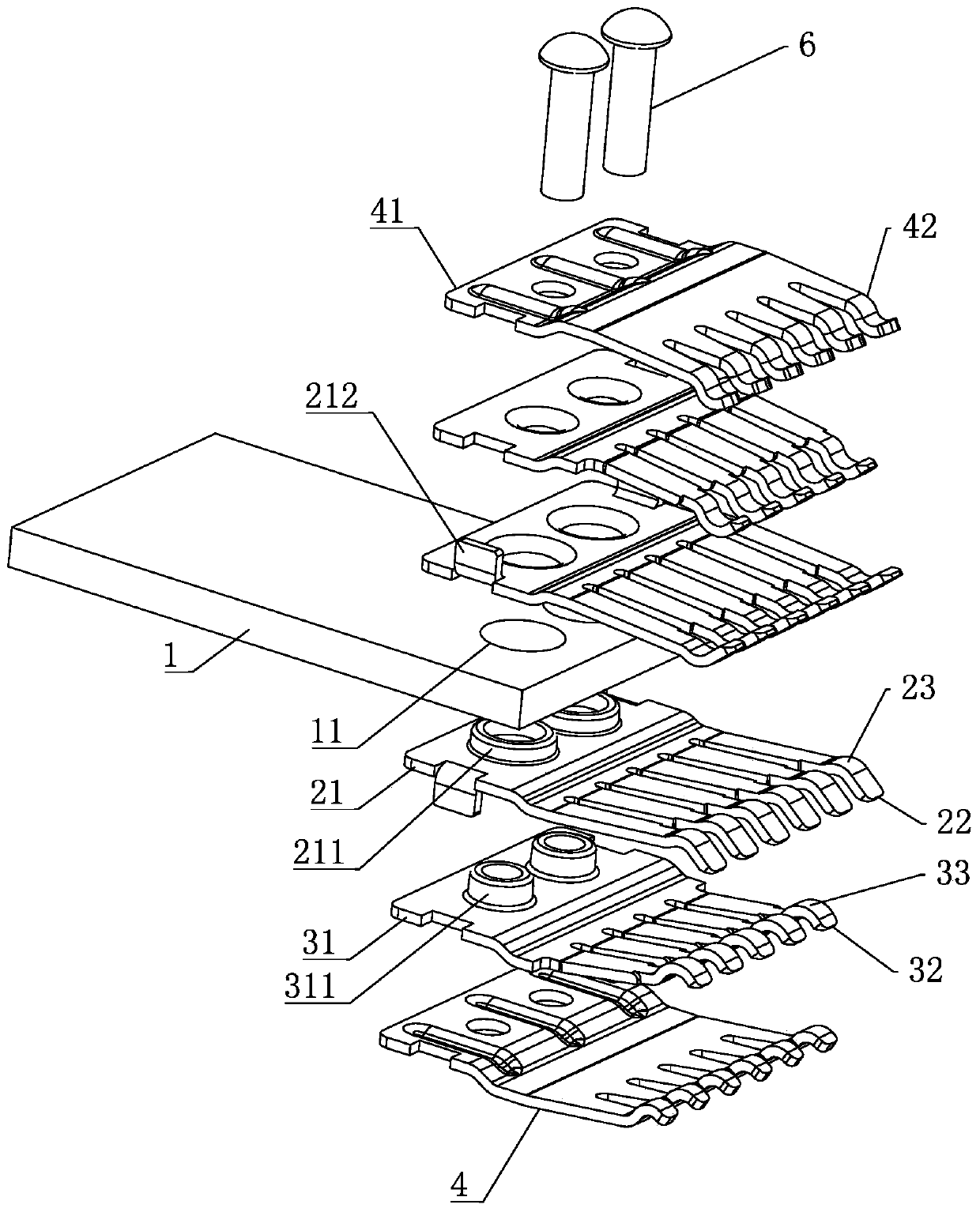

[0025] Such as Figure 2 to Figure 5 As shown, an embodiment of a double-reed socket structure in the present invention includes inner reeds 2 symmetrically arranged on both sides of the copper bar 1 to form sockets that are inserted into adapter pins, and the inner reeds 2. It includes a first connection part 21 that is fixedly matched with the copper bar and a plurality of first claws 22 arranged side by side on the first connection part 21. The first claws 22 have a first contact with the adapter pin A contact part 23; an outer reed 3 is provided on the outside of each inner reed, and the outer reeds on different sides of the copper bar are arranged symmetrically with each other. The outer reed 3 includes a second connection part 31 connected to the first connection part and parallel A plurality of seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com