Water segregator for vehicle-ship fuel cell engine

A fuel cell and engine technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of poor water separation effect, reduced service life, and gas leakage of the water separator, so as to avoid the risk of frequent opening and gas leakage , Reduce the risk of power consumption and life reduction, the effect of low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and embodiment is as follows.

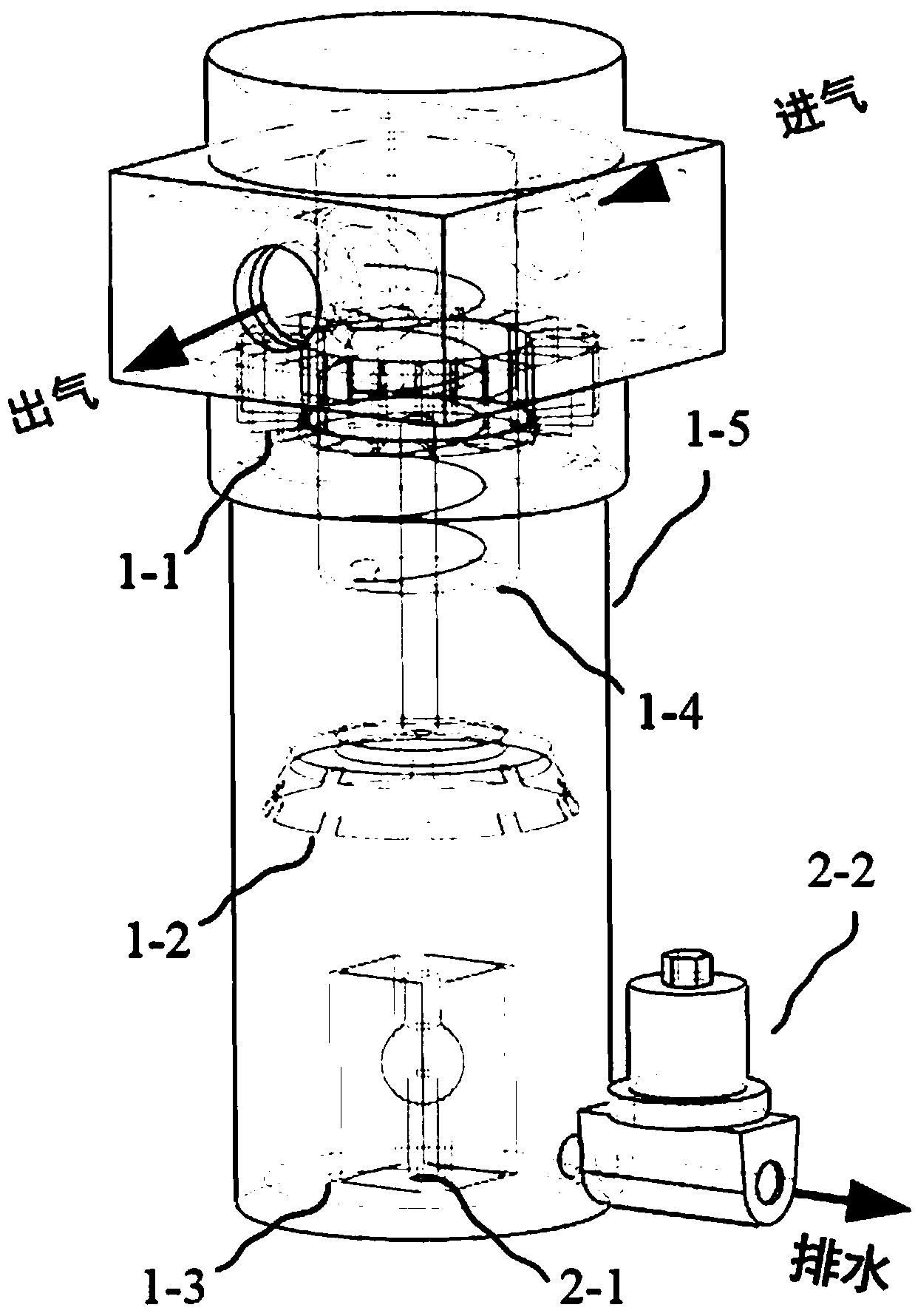

[0018] Such as figure 1 As shown, the present invention discloses a novel water separator for vehicle / ship fuel cell engines, including a gas-water separation unit and an automatic drainage unit. The air-water separation unit includes a vortex separator 1-1, a water retaining plate 1-2, a water stabilizing plate 1-3, an air duct 1-4, and a shell with an air inlet and an air outlet at the top and a drain at the bottom Body 1-5. The automatic drainage unit includes a liquid level switch 2-1 and a drainage valve 2-2. The air guide pipes 1-4 adopt a spiral design, which is used for the secondary water separation treatment of the gas to improve the water separation efficiency of the water separator. The water baffle 1-2 adopts the design that the outer edge is close to the inner wall of the housing 1-5 and has a water guide hole, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com