Efficient environmental-friendly paint spraying equipment

A kind of spraying equipment and environment-friendly technology, applied in the field of spraying, can solve the problems of incompleteness and single spraying function, and achieve the effect of preventing over-spraying, ensuring uniformity and preventing missed spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

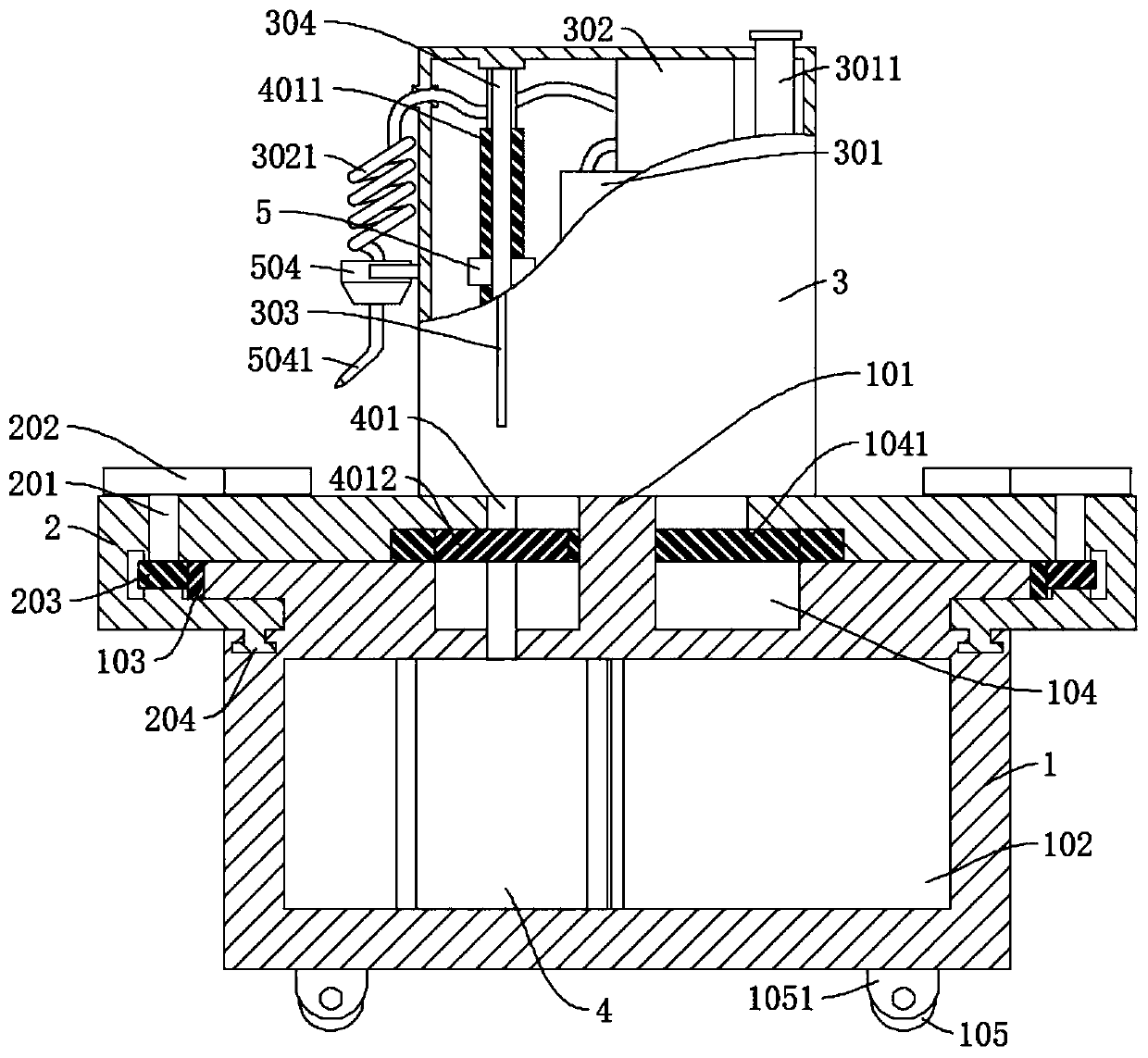

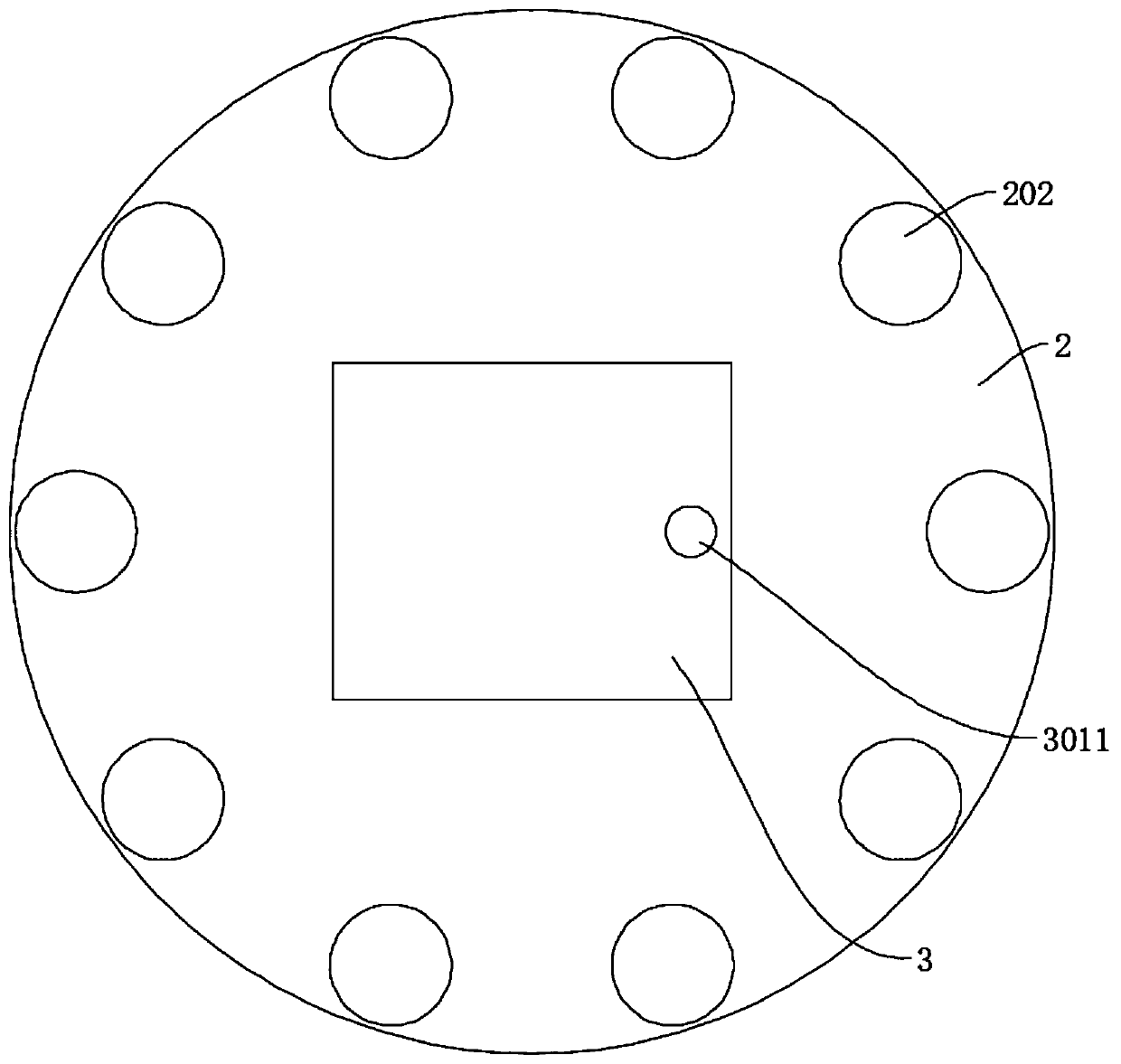

[0028] refer to figure 1 with image 3 , a high-efficiency and environment-friendly painting equipment, comprising an installation box 1, a booster pump 302 and a drive motor 4, the drive motor 4 is fixedly connected in the installation box 1, the top of the installation box 1 is fixedly connected with a support column 101, and the top of the support column 101 The work box 3 is fixedly connected, the liquid storage tank 301 is fixedly connected in the work box 3, the booster pump 302 is fixedly connected on the top of the liquid storage tank 301, and the output end of the drive motor 4 is fixedly connected with the drive shaft 401, and the drive shaft 401 is formed by From top to bottom, a reciprocating screw rod 4011 and a first gear 4012 are fixedly connected in turn. The reciprocating screw rod 4011 is arranged in the working box 3. The reciprocating screw rod 4011 is threadedly connected with a lifting plate 5, and the lifting plate 5 is fixedly connected with an extensio...

Embodiment 2

[0030] refer to figure 1 , is basically the same as Embodiment 1, and furthermore, the painting mechanism includes a shunt pipe 504 and a nozzle 5041, and the outer wall of the working box 3 is provided with a chute 303, and the extension rod 503 is slidably connected in the chute 303, and the shunt pipe 504 is fixedly connected to the The extension rod 503 is away from the end of the lifting plate 5, and the nozzle 5041 is fixedly connected to the bottom of the distribution pipe 504. The number of nozzles 5041 is multiple groups, and the multiple groups of nozzles 5041 are evenly distributed on the bottom of the distribution pipe 504. The material of the conduit 3021 is specifically PVC polymer. Vinyl chloride flexible gas pipe, the top of the liquid storage tank 301 is fixedly connected with the liquid injection pipe 3011, the liquid injection pipe 3011 runs through the inner wall of the working box 3 and extends to the top, and multiple sets of nozzles 5041 can ensure that t...

Embodiment 3

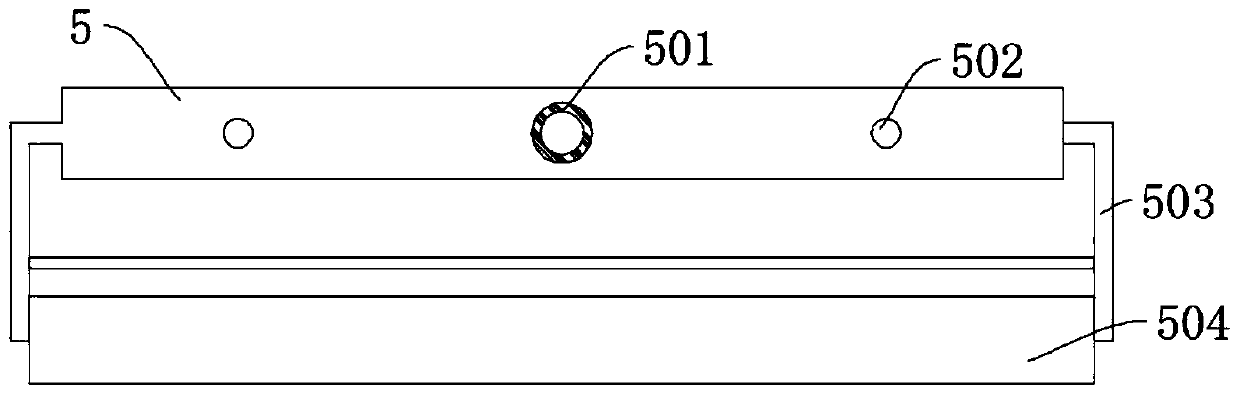

[0032] refer to figure 2 , is basically the same as Embodiment 1, and furthermore, the lifting plate 5 is provided with a threaded hole 501 and a through hole 502, the threaded hole 501 is matched with the reciprocating screw rod 4011, and the working box 3 is fixedly connected with a guide rod 304. The rod 304 runs through the through hole 502, and the guide rod 304 can ensure that the lifting plate 5 is stable up and down without fluctuation, thereby ensuring the uniformity of the nozzle 5041 during spraying and preventing missed spraying and overspraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com