Lithium battery visual detection device

A visual inspection device, lithium battery technology, applied in auxiliary devices, sorting, auxiliary welding equipment, etc., can solve the problems of visual fatigue, slow inspection speed of employees and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

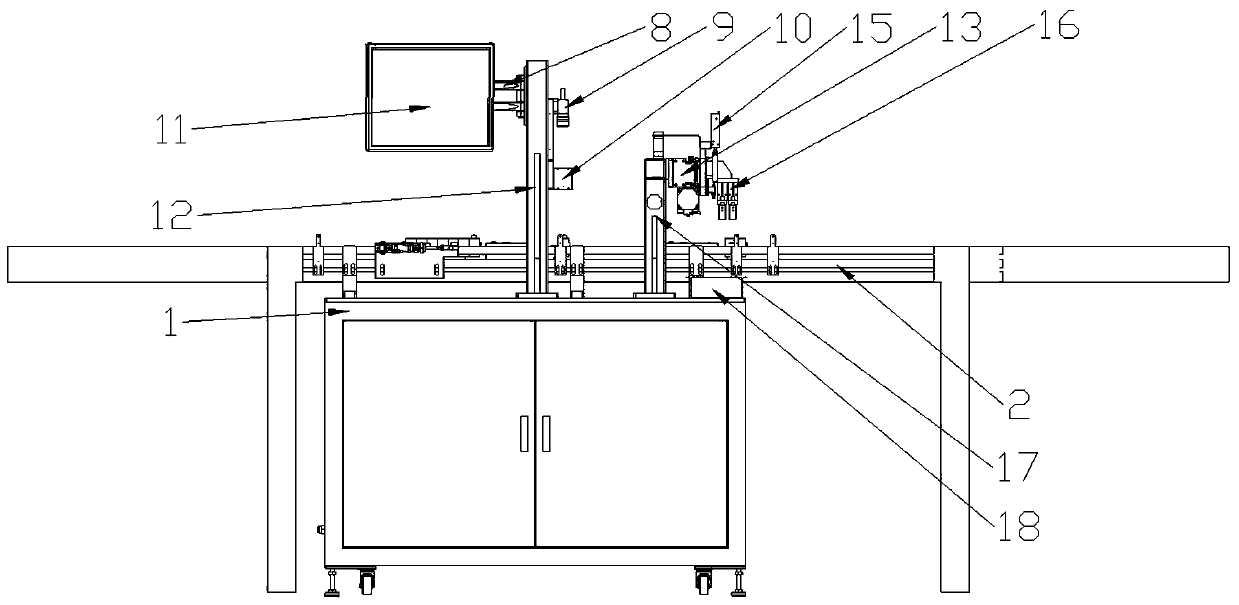

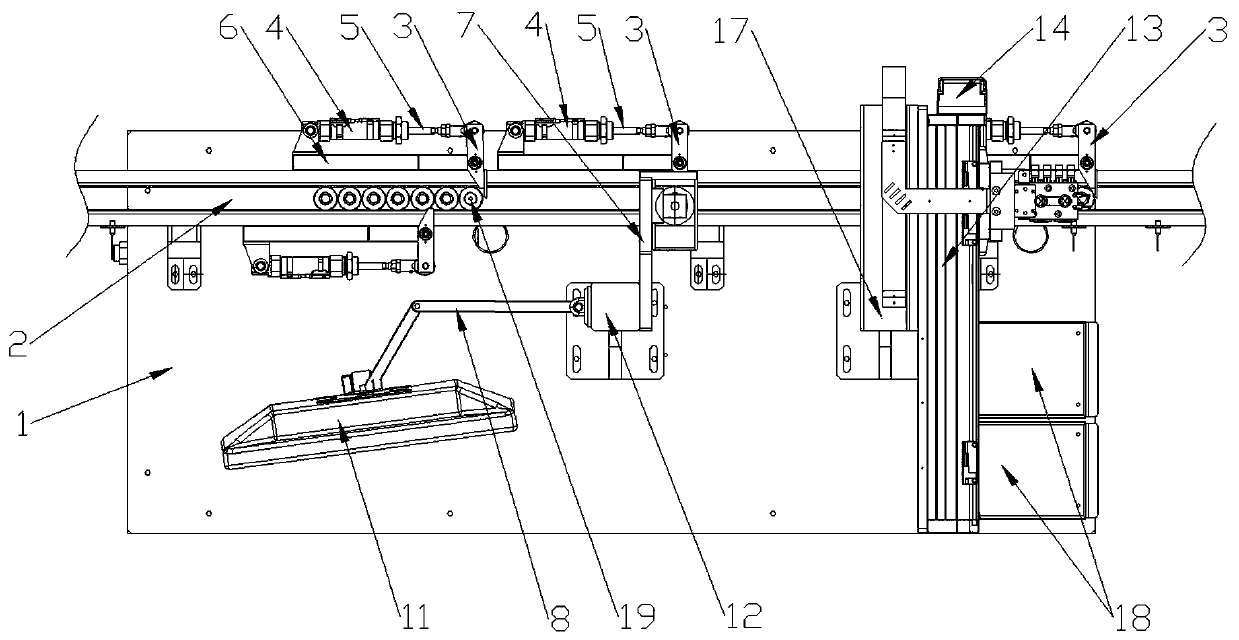

[0014] Such as figure 1 with figure 2 As shown, in this embodiment, the present invention includes a workbench 1, a battery distributing mechanism, a visual photographing mechanism, an NG product rejecting mechanism and a conveying line 2, the battery distributing mechanism, the visual photographing mechanism and the NG product The product rejecting mechanism is sequentially arranged on the workbench 1, and the visual camera mechanism includes a first material blocking mechanism and a CCD detection module, and the first material blocking mechanism and the CCD detection module are respectively arranged on the conveying On both sides of the line 2, the NG product rejecting mechanism includes a second stopper mechanism and a gripper module, the second stopper mechanism and the gripper module are respectively arranged on both sides of the conveying line 2, Both the photographing part of the CCD detection module and the clamping part of the gripper module are located above the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com