Multi-faceted washing equipment for cullet for glass making

A cullet and glass technology, which is applied in the field of cullet multi-faceted washing equipment for glass production, can solve the problems of failing to meet the hygienic standards of cullet, incomplete washing, sticking impurities, etc., to avoid random discharge of waste water, comprehensive washing, and reduce damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

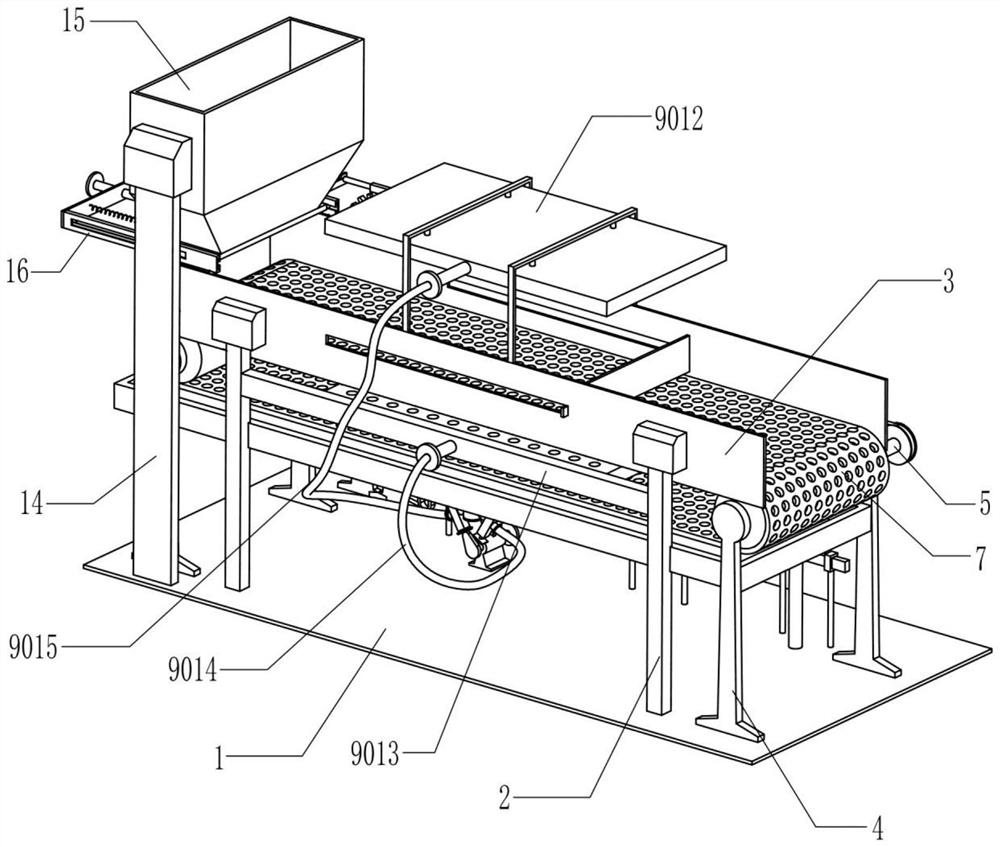

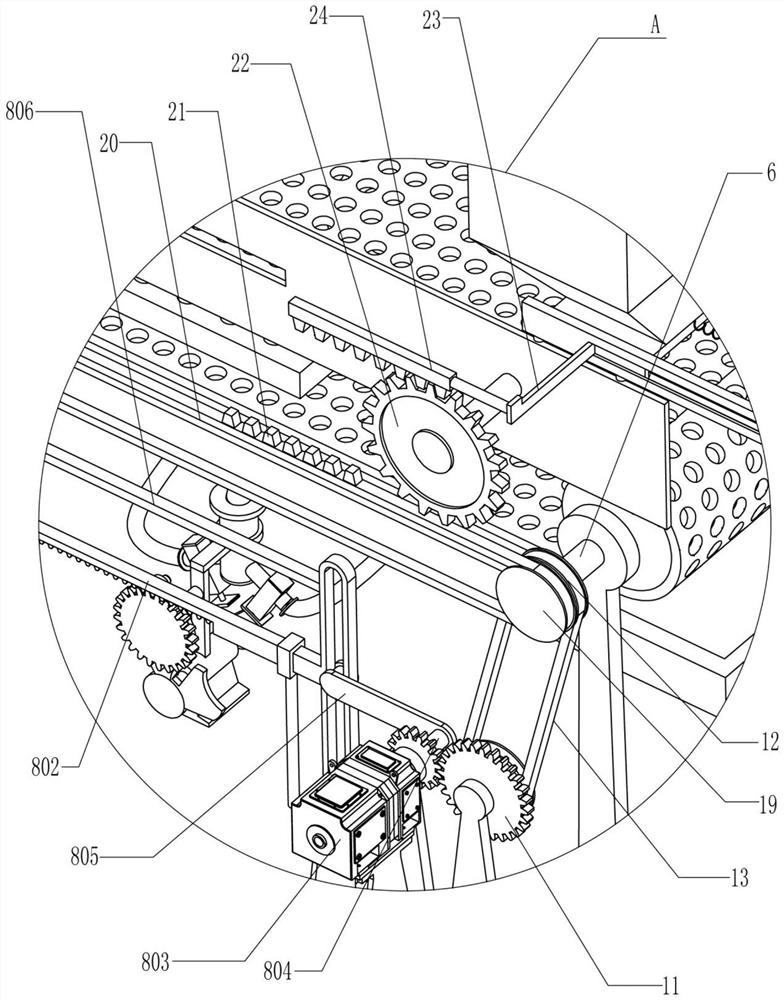

[0024] A multi-faceted washing equipment for cullet for glass making, such as Figure 1-6As shown, it includes a bottom plate 1, a support plate 2, a limit plate 3, a support seat 4, a first transmission roller 5, a second transmission roller 6, a mesh conveyor belt 7, a cullet flattening device 8, a servo motor 803, The first rotating shaft 804, the water spray direction adjusting device 9, the small diameter gear 10, the large diameter gear 11, the first pulley 12, the first flat belt 13, the top plate 14, the discharge frame 15, the guide frame 16, the material retaining plate 17 and The second compression spring 18, three supporting plates 2 are fixedly installed on the upper side of the base plate 1, and two limiting plates 3 arranged in parallel are fixedly installed on the upper ends of the three supporting plates 2, and both limiting plates 3 are There is a chute, and two sets of support bases 4 are fixedly installed on the left and right ends of the upper side of the ...

Embodiment 2

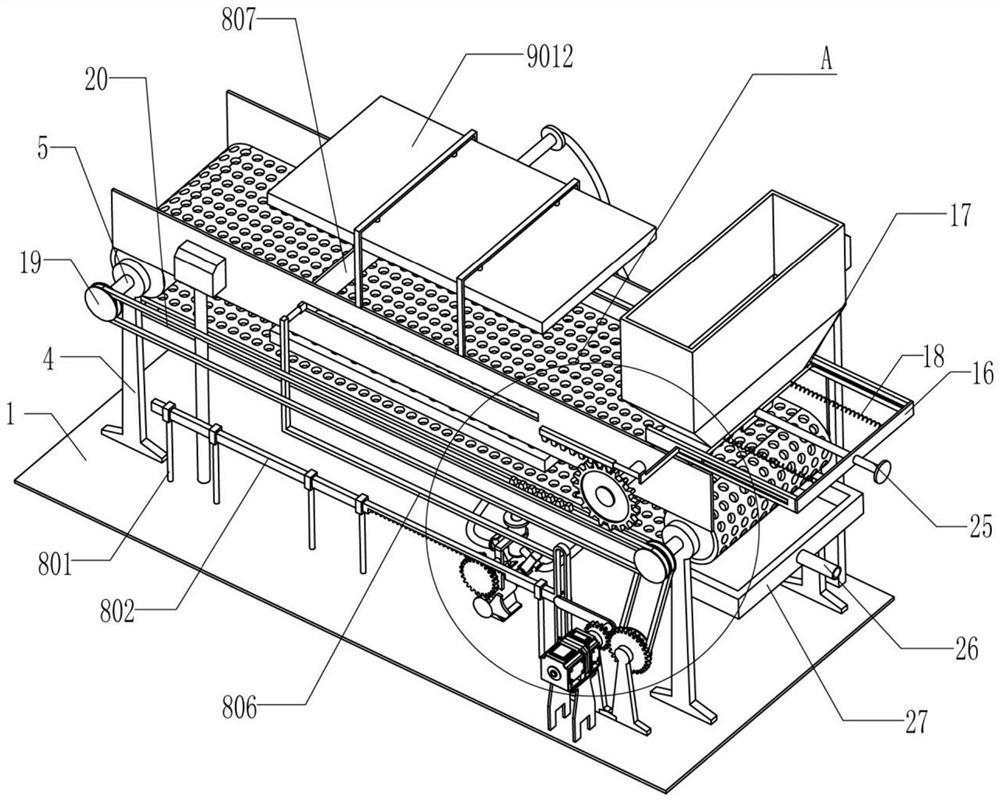

[0031] On the basis of Example 1, as Figure 2-3 As shown, it also includes a second pulley 19, a second flat belt 20, a tooth block 21, a second drive gear 22, a connecting rod 23 and a rack 24, one end of the first drive roller 5 and the second drive roller 6 A second pulley 19 is installed at the rear end of the second pulley, and a second flat belt 20 is connected between the two second pulleys 19. Seven tooth blocks 21 are installed on the second flat belt 20, and the second drive gear 22 is installed on the rear side of one of the limiting plates 3 through a rotating shaft and meshes with seven tooth blocks 21. The connecting rod 23 is fixedly installed on the material blocking plate 17 and is in sliding contact with the guide frame 16. The rack 24 It is fixedly installed on the right end of the connecting rod 23 and meshes with the second driving gear 22 .

[0032] In specific use, the clockwise rotation of the second drive roller 6 will drive one of the second pulleys...

Embodiment 3

[0034] On the basis of Example 2, such as figure 2 As shown, a pull rod 25 is also included. The pull rod 25 is fixedly installed on the left side of the material baffle 17 and passes through the guide frame 16. The function of the pull rod 25 is convenient for the staff to manually pull the material baffle 17 when necessary. move.

[0035] Such as figure 2 As shown, it also includes a drain pipe 26 and a liquid collection plate 27. The liquid collection plate 27 used to collect the waste water generated by the washing operation of broken glass is fixedly installed on two sets of support bases 4, and the liquid collection plate 27 is positioned at the below of network port conveyer belt 7, and the left part of described liquid collecting plate 27 offers a round hole and is equipped with drain pipe 26 in the round hole, and described drain pipe 26 is used for collecting the liquid collected by liquid collecting plate 27. Waste water is discharged.

[0036]In specific use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com