Easy-to-form polypropylene for bubble cap and preparation method of easy-to-form polypropylene

A technology of polypropylene and blisters, which is applied in the field of polypropylene for blisters and its preparation, which can solve problems such as poor transparency, affecting the preparation effect of blisters, and difficulty in molding, and achieve the effects of not being easy to break, eliminating adverse effects, and being easy to shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

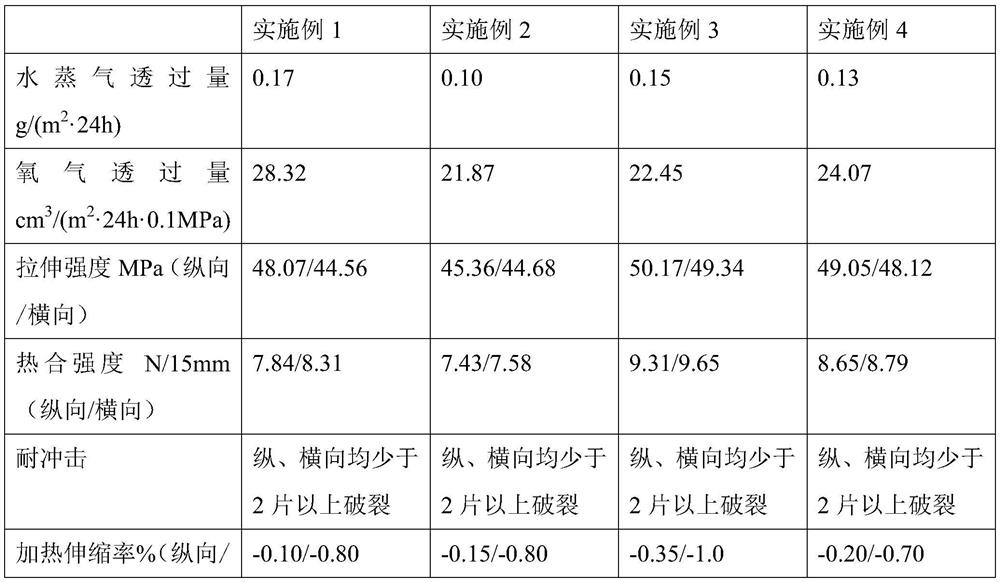

Examples

Embodiment 1

[0027] This embodiment provides an easy-to-form polypropylene for blisters. The composition ratio of main raw materials includes: antioxidant 1010 is 450ppm, antioxidant 168 is 500ppm, acid absorbing agent is 350ppm, slip agent is 150ppm, transparent The nucleating agent is 3500ppm, and polypropylene is the balance; wherein the amount of each raw material added is optimized based on the total amount of raw materials added.

[0028] Then the preparation method step of the polypropylene of above-mentioned raw material is:

[0029] Step 1: Feeding, put the raw materials in the loading box;

[0030] Step 2: Pass the material in the above-mentioned material frame through the air conveyor, enter the extrusion plasticization, and after being extruded through the die, it is sequentially extruded by three rollers, wherein the speed of the fixed roller is controlled at 24.32m / min, and the fixed roller The temperature is 40°C, the speed of the pressing roller is 24.54m / min, the temperat...

Embodiment 2

[0034] This embodiment is different from Embodiment 1 in that the raw material composition of the polypropylene for the blister is different, and the rest are the same as in Embodiment 1.

[0035] This embodiment 2 provides an easy-to-form polypropylene for blisters. The composition ratio of the main raw materials includes: 550ppm for antioxidant 1010, 1500ppm for antioxidant 168, 450ppm for acid absorbing agent, 250ppm for slip agent, transparent The nucleating agent is 4500ppm, and the polypropylene is the balance; wherein the amount of each raw material added is optimized based on the total amount of raw materials added.

Embodiment 3

[0037] This embodiment is different from Embodiment 1 in that the raw material composition of the polypropylene for the blister is different, and the rest are the same as in Embodiment 1.

[0038] This embodiment 3 provides an easy-to-form polypropylene for blisters. The main raw material composition ratio includes: antioxidant 1010 is 500ppm, antioxidant 168 is 1000ppm, acid absorbing agent is 400ppm, slip agent is 200ppm, transparent The nucleating agent is 4000ppm, and polypropylene is the balance; wherein the amount of each raw material added is optimized based on the total amount of raw materials added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com