Multi-directional rotary forming hydraulic machine

A technology of rotary forming and hydraulic press, which is applied to forging presses, forging presses, forging press driving devices, etc., can solve the problems of low processing efficiency and achieve the effect of increasing the processing range and precise and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

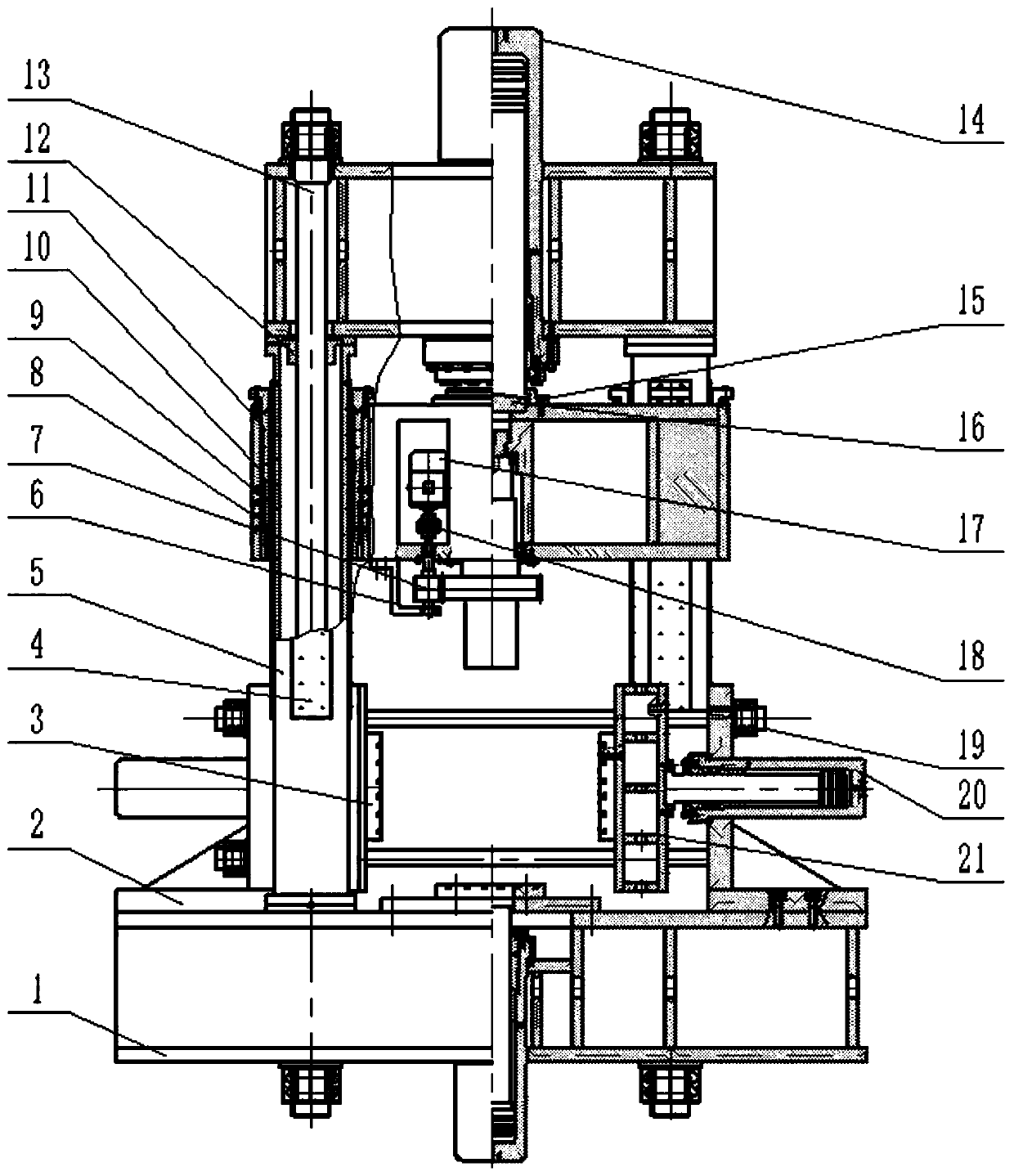

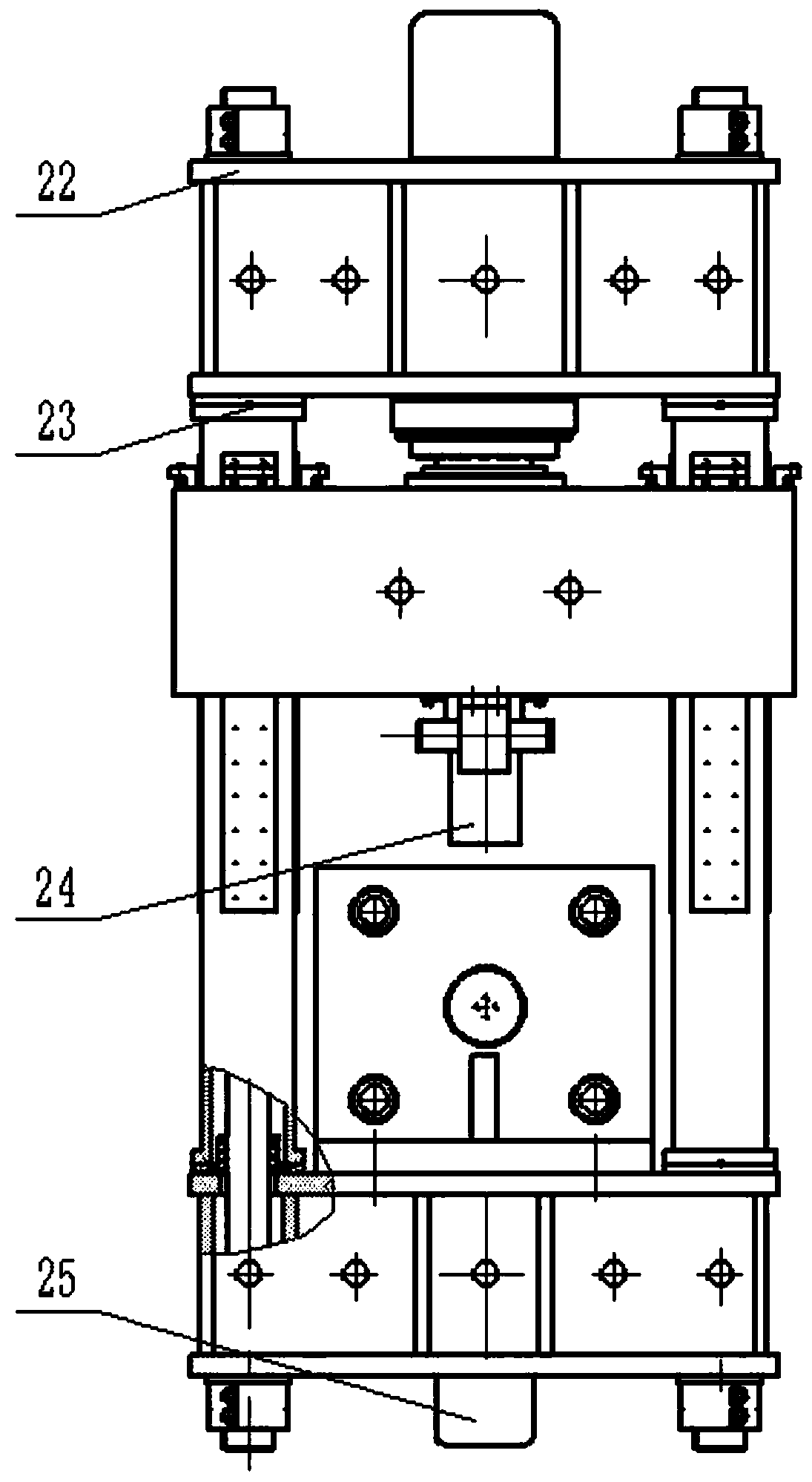

[0029] Such as Figure 1-6 As shown, this embodiment provides a multi-directional rotary forming hydraulic machine, which mainly includes a square column 5, a large tie rod 13, a small tie rod 19, an upper beam 22, a main piston cylinder 14, a movable beam 11, a large gear shaft 24, and a pinion shaft 7. Three-phase asynchronous motor 17, lower beam 1, bottom piston cylinder 25, side beam 2, side piston cylinder 20, side movable beam 21, workbench 3.

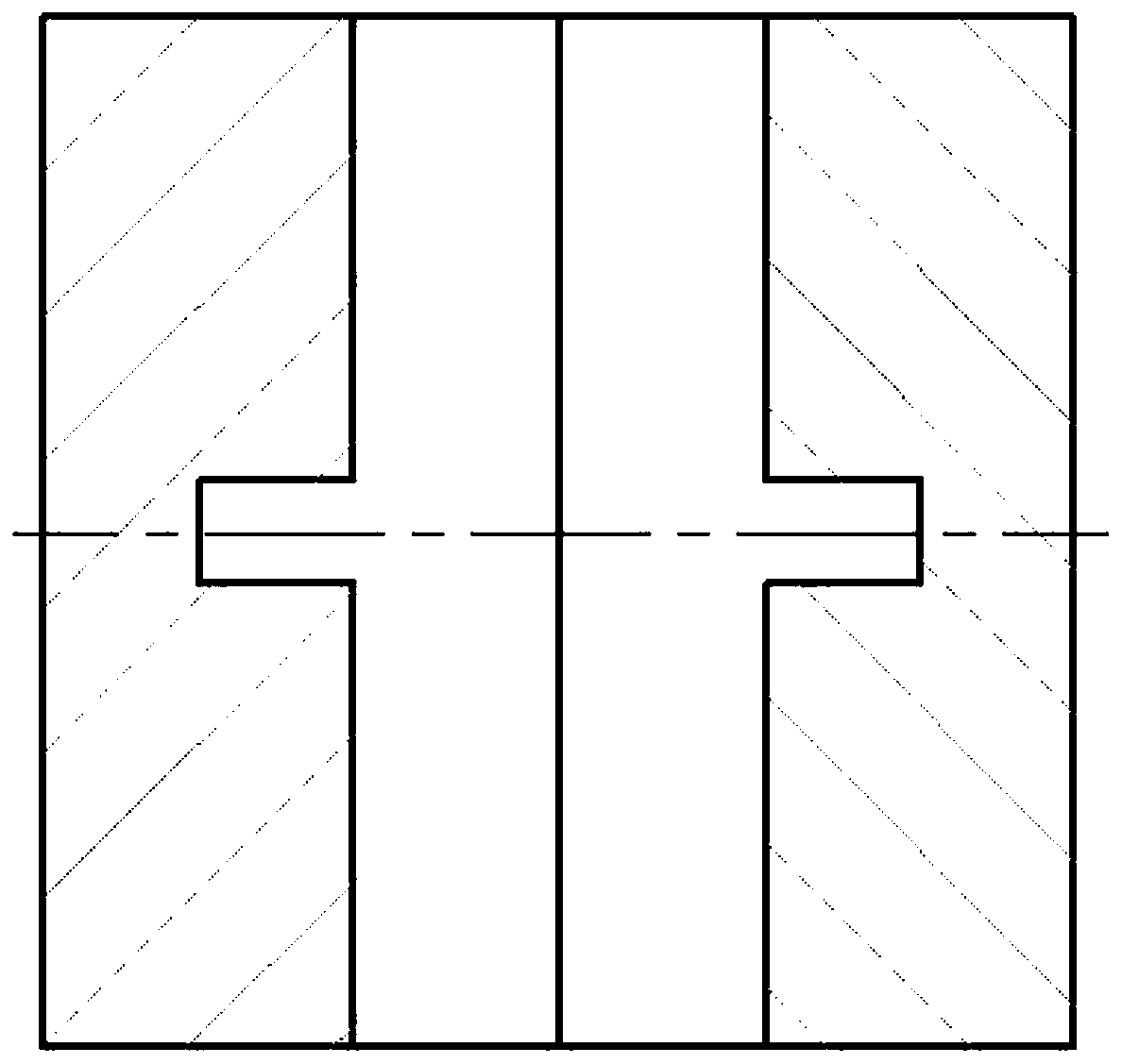

[0030] In this embodiment, the square column, the large tie rods, the small tie rods, the upper beam, the movable beam, the lower beam, the side beams, and the side movable beam constitute the frame structure of the hydraulic machine. The upper beam is located on the upper part of the square column and is rigidly connected with the square column. The main piston cylinder is installed on the upper beam; the movable beam is located below the upper beam and is rigidly connected with the piston rod of the main piston cylinder. A th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com