Laser processing device for special-shaped light and thin flexible titanium alloy part for aero-engine

An aero-engine and laser processing technology, which is applied in the field of titanium material processing, can solve the problems of increased processing of titanium alloy material plates, difficulty in processing processing accuracy, and inability to meet quality requirements, so as to reduce processing costs, improve processing accuracy, and simplify manual operations. Effects of Difficulty and Effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

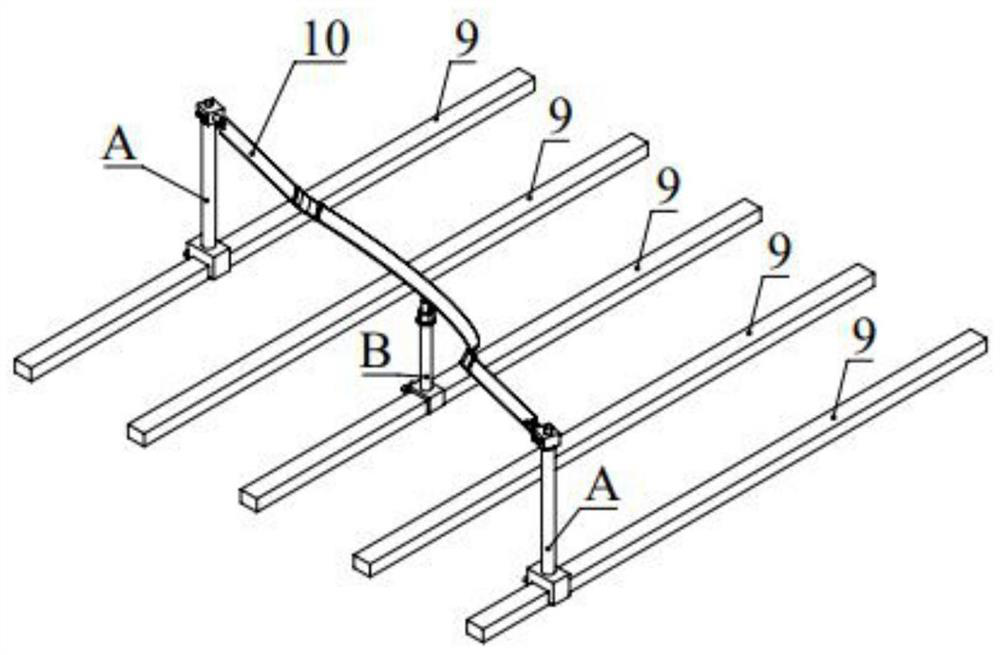

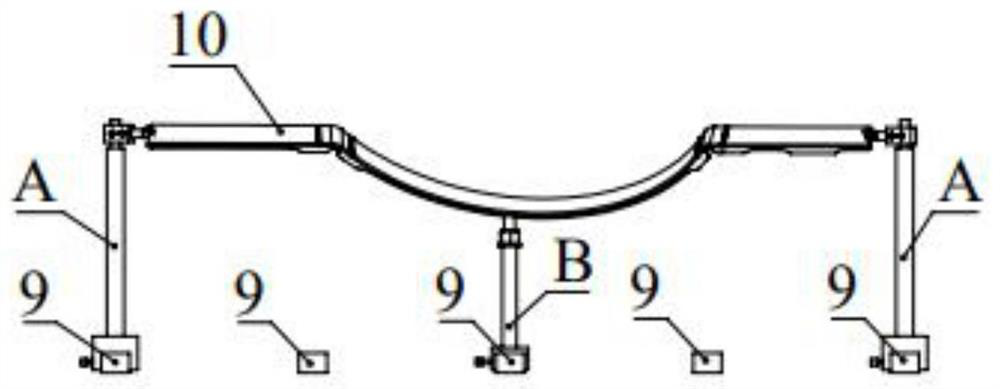

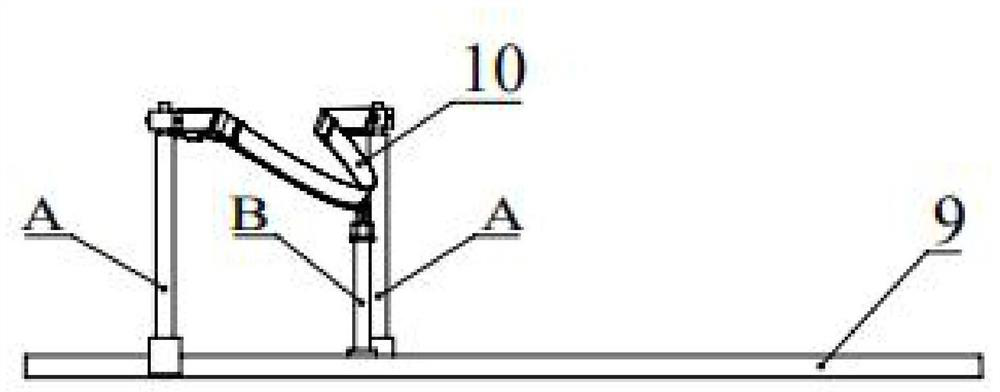

[0031] Such as Figure 1 to Figure 7 As shown, it is a schematic view of the laser processing device of the present invention processing a special-shaped titanium alloy sheet metal workpiece on the guide rail of the laser processing platform. It includes the guide rail 9 of the existing laser cutting platform, and also includes two sets of column assemblies A and a set of support rod assemblies B.

[0032] The column assembly A includes a column 1, and a universal device is installed on the top of the column 1. The universal device includes a universal block 2 and a universal head 3. One end of the universal head 3 is horizontally inserted into the universal It is fixed in the screw hole of the block 2, and the other end is provided with a draw-in groove 32 opened horizontally; the root of the column 1 is provided with a first guide groove 91...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com