A 3D printed pressure vessel mapping test system

A pressure vessel and test system technology, applied in the field of 3D printing, can solve the problems of easy existence, single self-correction method, single drawing generation, etc., to achieve the effect of reliable and accurate construction, increasing application scenarios, and efficient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

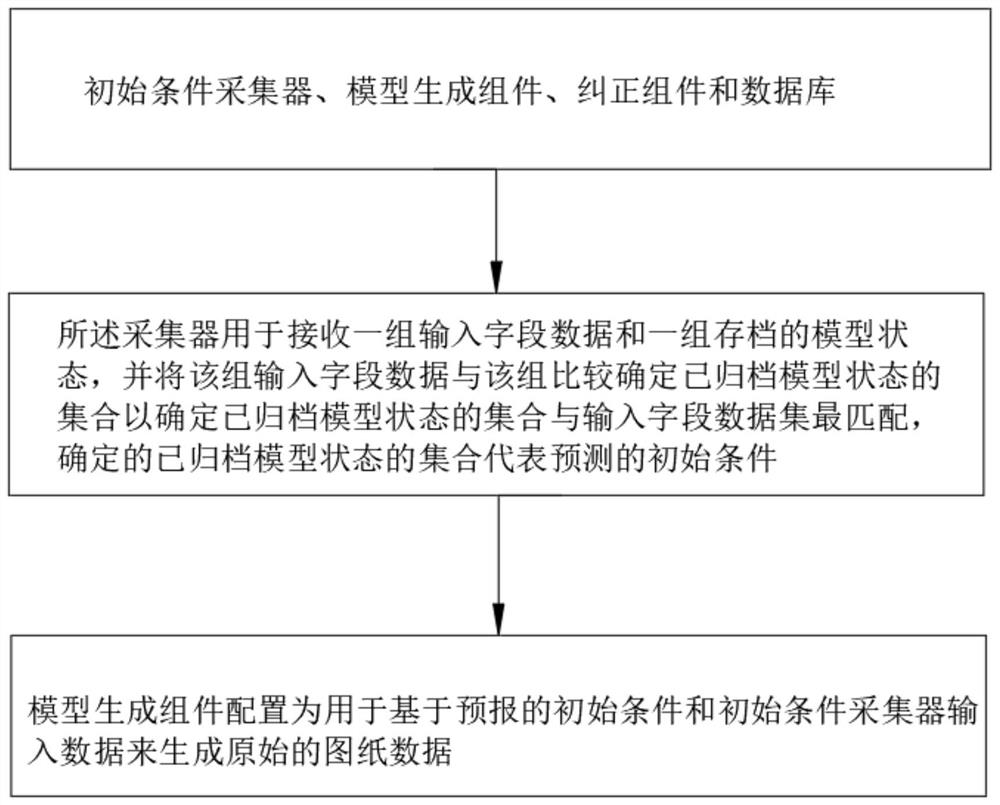

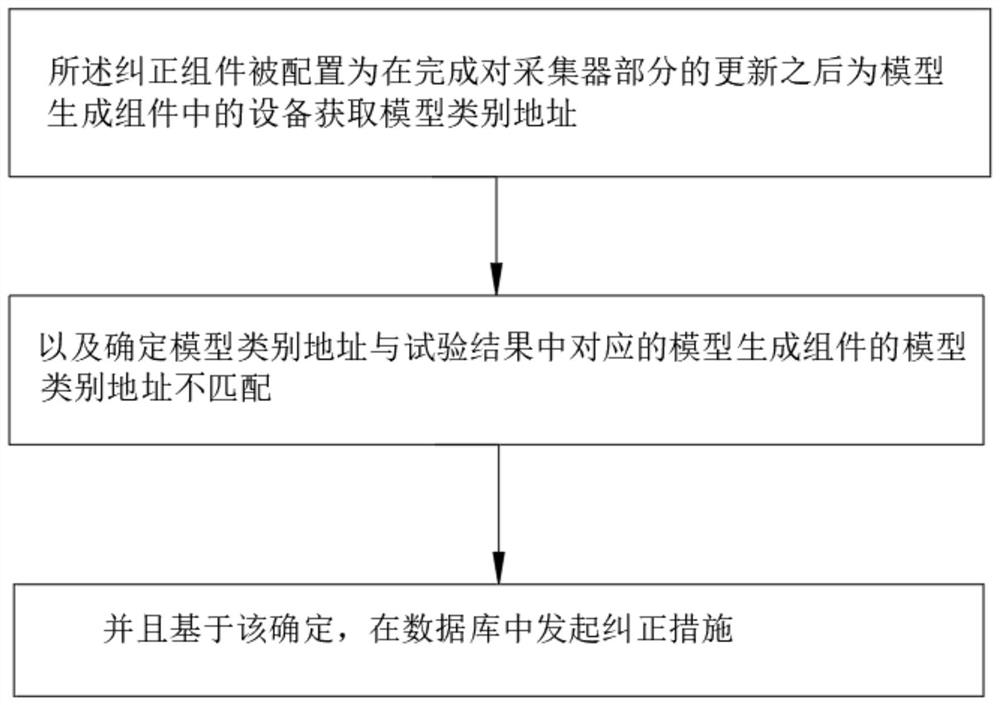

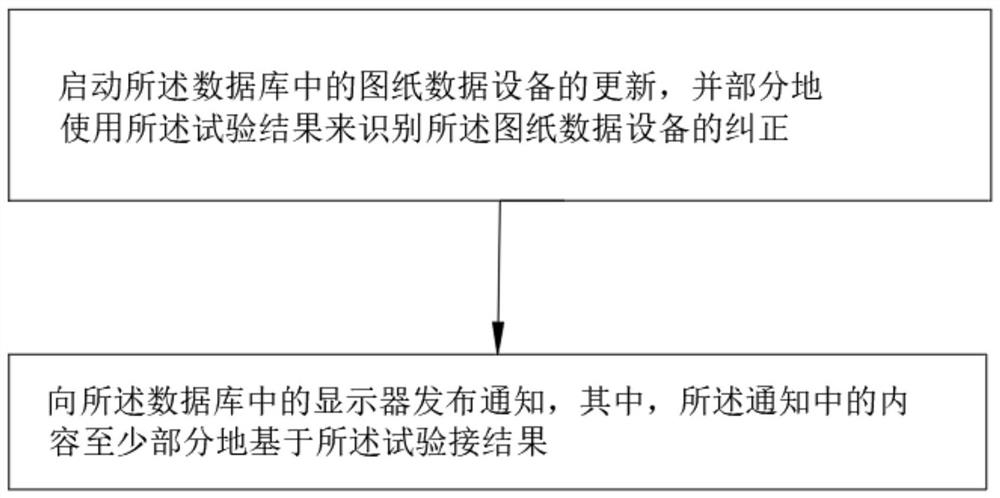

Embodiment 1

[0027] Embodiment 1: A 3D printed pressure vessel mapping test system, including an initial condition collector, a model generation component, a correction component and a database, the collector is used to receive a set of input field data and a set of archived model states, and compares the set of input field data to the set of determined archived model states to determine that the set of archived model states best matches the set of input field data, the determined set of archived model states represents initial conditions for prediction; the model generation component Configured to generate raw drawing data based on predicted initial conditions and initial condition collector input data. The correction component is configured to obtain a model class address for a device in the model generation component after completing an update to the collector portion; and determine that the model class address does not match a model class address of a corresponding model generation comp...

Embodiment 2

[0028]Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis of it. Specifically, this embodiment provides a 3D printed pressure vessel mapping test system, including an initial condition collector, a model generation component, a correction component, and a database, the collector being configured to receive a set of input field data and a set of archived model states, and compare the set of input field data with the set to determine an archived model state Aggregation to determine the set of archived model states that best matches the input field dataset, the determined set of archived model states representing the predicted initial conditions; the model generation component is configured for initial conditions based on forecasts and initial condition collector input data To generate the original drawing data; specifically, the whole system includes an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com