Logistics transfer loading and unloading device

A loading and unloading device and logistics technology, applied in the direction of transportation and packaging, multi-axis trolleys, sleds, etc., can solve the problems of multiple physical strength, low handling efficiency, and different heights, and achieve improved stability, improved loading and unloading efficiency, and convenient loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

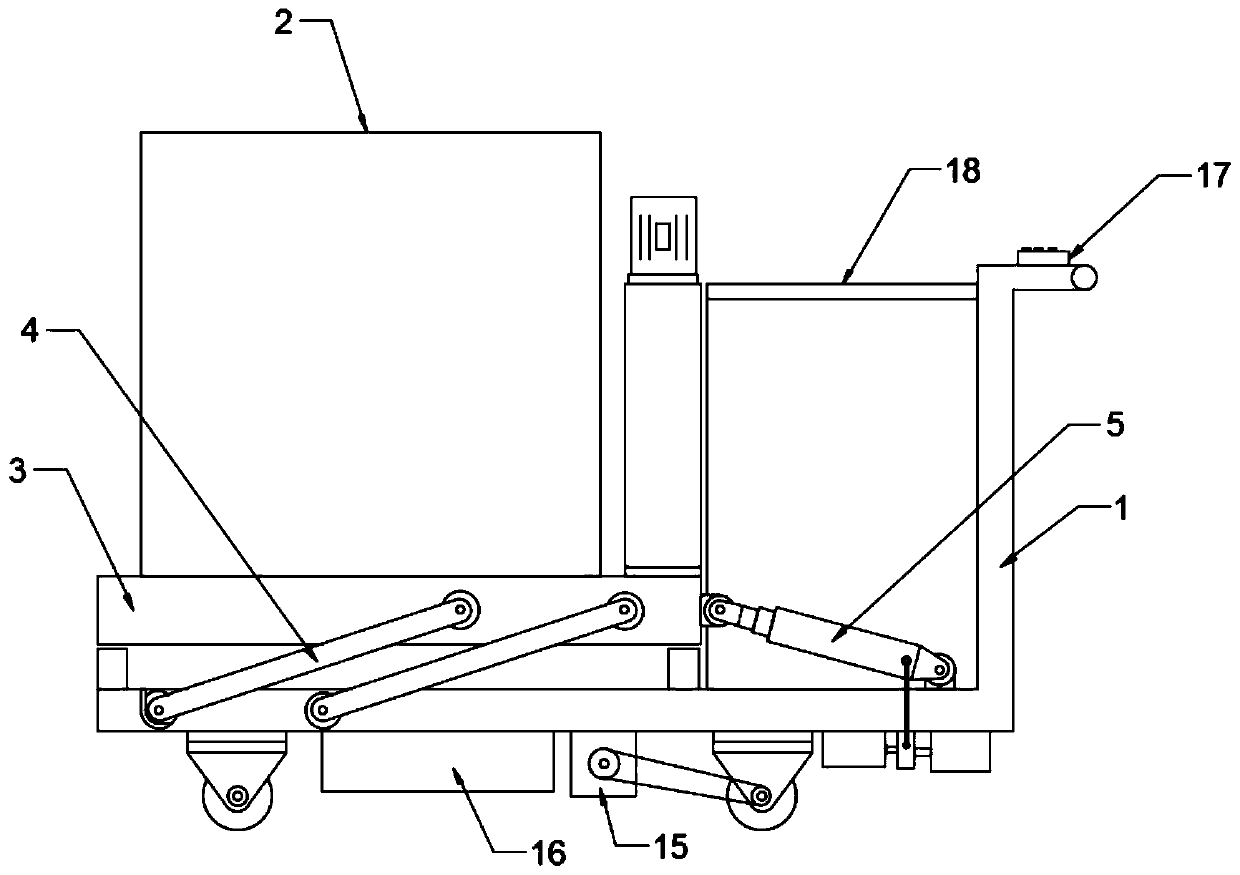

[0022] see figure 1 , in an embodiment of the present invention, a logistics transfer and loading and unloading device includes a trolley 1; a cargo bucket 2 is arranged above the trolley 1, and the cargo bucket 2 is a hollow box structure with an open front end and an upper end, which is convenient for loading goods. The bottom of the bucket 2 is connected with a lifting platform 3, and the front and rear walls of the lifting platform 3 are hinged with two sets of connecting rods 4 arranged in parallel, and the lower ends of the connecting rods 4 are hinged with the bottom plate of the cart 1; the end of the lifting head 3 is hinged with a hydraulic cylinder 5 , the hydraulic cylinder 5 is hinged with the bottom plate of the trolley 1 through the hinge seat; specifically, the hydraulic cylinder 5 drives the piston rod to stretch out and then pushes the lifting table 3 to rise and extend to the front side, so that the cargo bucket 2 is connected with the cargo bucket 2 to be un...

Embodiment 2

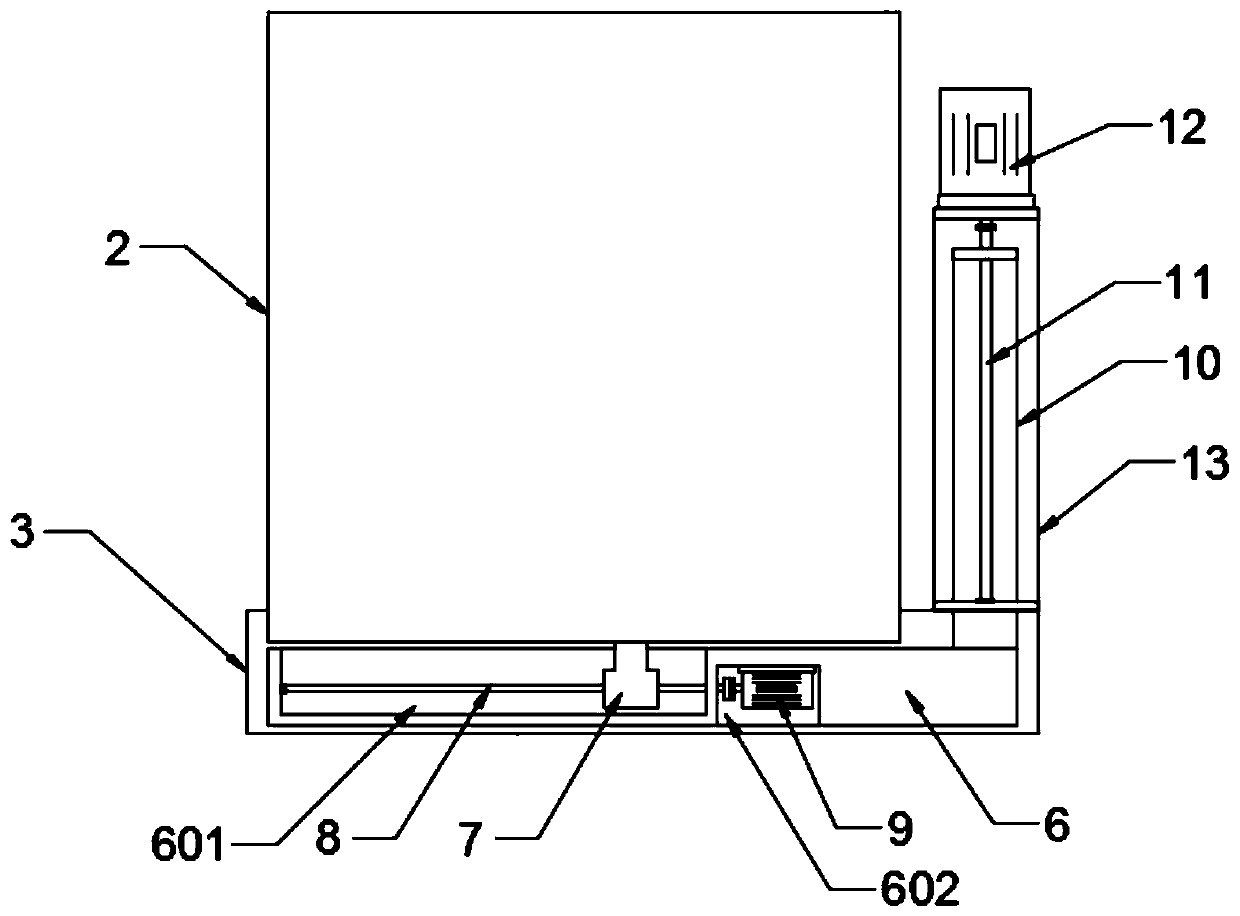

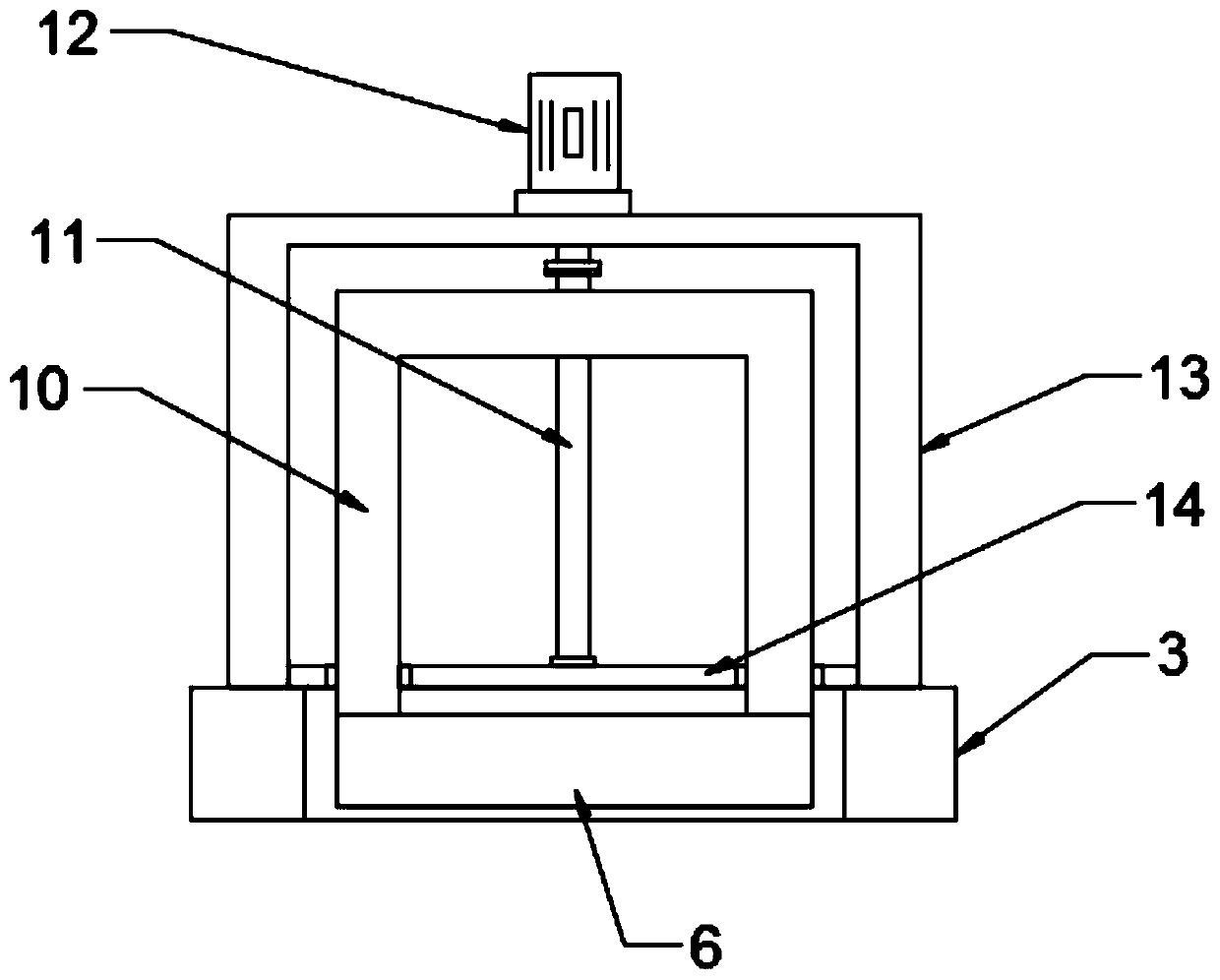

[0025] see Figure 1-6 , a logistics transfer loading and unloading device, including a cart 1; a cargo bucket 2 is arranged above the trolley 1, and the cargo bucket 2 is a hollow box structure with an open front end and an upper end, which is convenient for loading cargo. Platform 3, the front and rear walls of lifting platform 3 are hinged with two sets of connecting rods 4 arranged in parallel, the lower ends of connecting rods 4 are hinged with the bottom plate of cart 1; the end of lifting head 3 is hinged with hydraulic cylinder 5, and hydraulic cylinder 5 is hinged The seat is hinged with the bottom plate of the trolley 1; specifically, the hydraulic cylinder 5 drives the piston rod to stretch out and then pushes the lifting platform 3 to rise and stretch out to the front side, so that the cargo bucket 2 is connected to the truck compartment or train to be unloaded or loaded. The height of the carriages is consistent, which is convenient for loading and unloading opera...

Embodiment 3

[0030] see Figure 1-6 , a logistics transfer loading and unloading device, including a cart 1; a cargo bucket 2 is arranged above the trolley 1, and the cargo bucket 2 is a hollow box structure with an open front end and an upper end, which is convenient for loading cargo. Platform 3, the front and rear walls of lifting platform 3 are hinged with two sets of connecting rods 4 arranged in parallel, the lower ends of connecting rods 4 are hinged with the bottom plate of cart 1; the end of lifting head 3 is hinged with hydraulic cylinder 5, and hydraulic cylinder 5 is hinged The seat is hinged with the bottom plate of the trolley 1; specifically, the hydraulic cylinder 5 drives the piston rod to stretch out and then pushes the lifting platform 3 to rise and stretch out to the front side, so that the cargo bucket 2 is connected to the truck compartment or train to be unloaded or loaded. The height of the carriages is consistent, which is convenient for loading and unloading opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com