Packaging method

A packaging method and film technology, applied in the field of packaging, can solve the problems of complex buffer belt structure and complicated steps, and achieve the effects of convenient cost and simple packaging steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

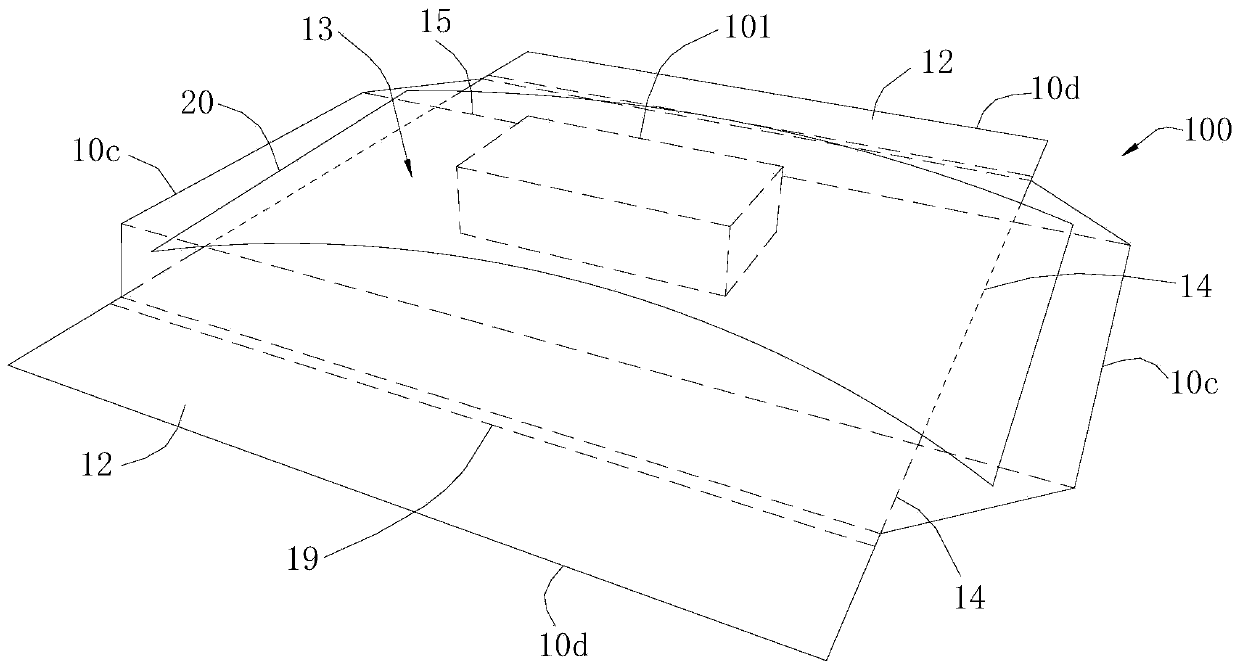

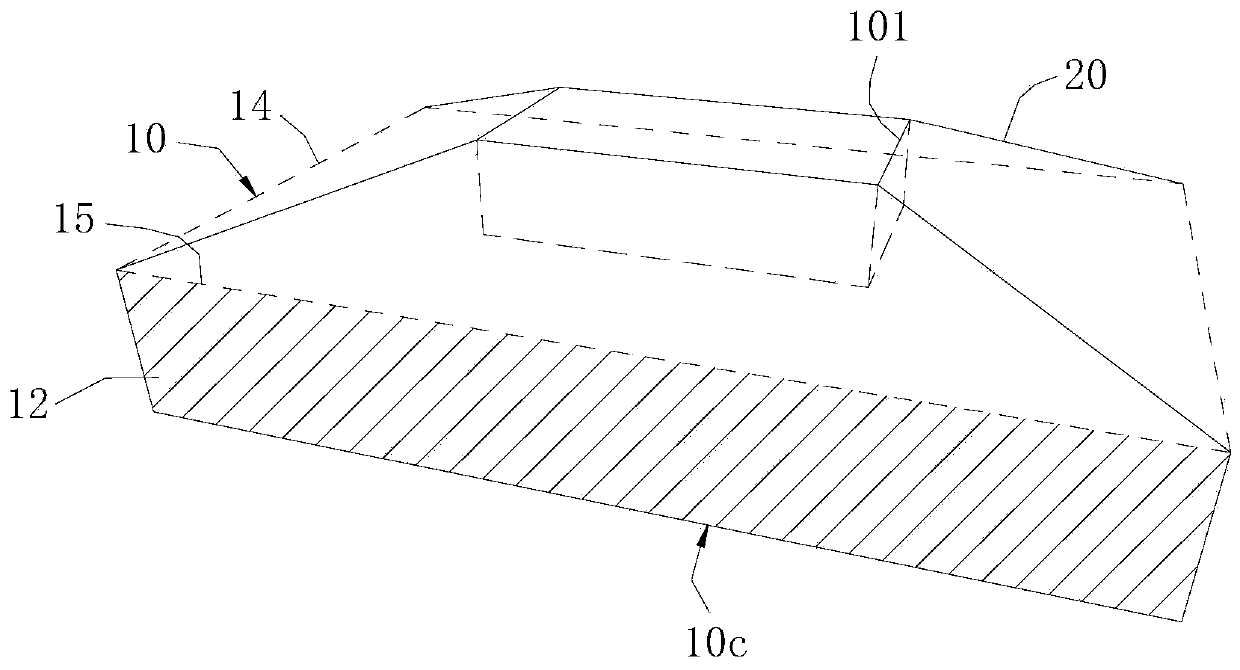

[0067] Such as Figure 4 and Figure 5 As shown, the base plate 10 has a front face 10a and a bottom face 10b oppositely disposed, and the bottom face 10b is coated with a waterproof layer 11 . The film 20 is located on the front side 10 a of the cardboard 10 , and the film 20 is fixed around the front side 10 a of the base plate 10 to form a sealed area 13 for accommodating products 101 with the front side 10 a.

[0068] It can be understood that the packaging structure 100 forms a sealing area 13 for accommodating the product 101 by coating the waterproof layer 11 on the bottom surface 10b of the bottom plate 10, and bonding the film 20 to the front surface 10a in a sealed manner; thus, the product 101 is in a surrounding sealed environment, which prevents water vapor exchange, that is, the packaging structure has a waterproof and moisture-proof function. At the same time, since the packaging structure 100 is provided with the waterproof layer 11 combined with sealing, it ...

Embodiment 2

[0103] Embodiment 2 is basically the same as Embodiment 1, except that: in Embodiment 2, the pressure-sensitive adhesive 21 is coated on the base plate. Therefore, the structure of the bottom plate 10 and the process of packaging the product 101 with the packaging structure 100 are slightly changed, which will be described in detail below:

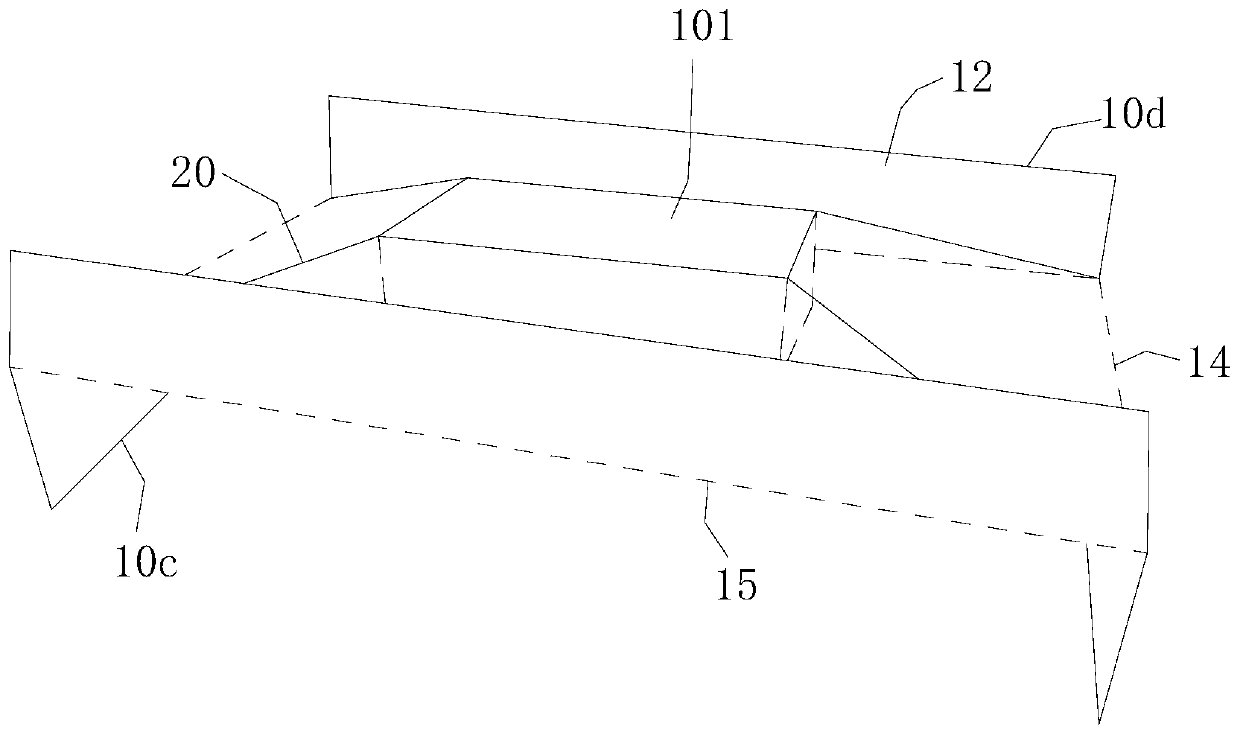

[0104] Such as Figure 8 to Figure 12 As shown, in this embodiment, the bottom plate 10 has two sets of second crimping lines 15 and two sets of folding lines 19 . Located on the same side of the base plate 10 , the distance between the second crimping line 15 and the folding line 19 is F1, and the distance between the folding line 19 and the side of the corresponding side of the base plate 10 is F2.

[0105] Each group of second crimping lines 15 includes two second crimping lines 15 arranged at intervals, and each group of folding lines 19 also includes two folding lines 19 arranged at intervals. In each set of second crimping lines 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com