a packaging system

A packaging system and packaging film technology, which is applied in packaging, packaging paper, transportation packaging, etc., can solve the problems of equipment manufacturing cost, high operation and maintenance cost, low production efficiency, high packaging cost, etc., and achieve good appearance and low consumption. The effect of less and low packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

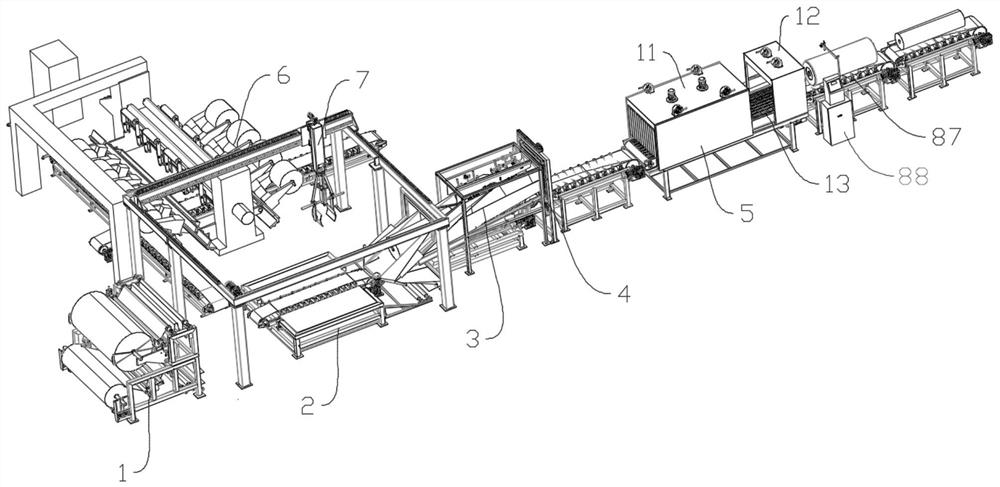

[0063] Such as Figure 1-Figure 17 As shown, this embodiment provides a packaging system, including a packaging film unwinding mechanism 1, an intelligent weighing and conveying device 2, a packaging film wrapping mechanism 3, a packaging film cutting mechanism 4, and a packaging film shrink furnace 5 arranged in sequence. The packaging film unwinding mechanism 1 is equipped with an inner packaging film roll and a heat-shrinkable film roll. The intelligent weighing and conveying device 2 weighs the object to be packaged and transmits the data to the control center, and then transports the object to be packaged to the packaging film wrapper Mechanism 3, the lower part of the intelligent weighing conveying device 2 is provided with a channel for the passage of the inner packaging film and the heat-shrinkable film released from the packaging film unwinding mechanism 1 at the same time, and the inner packaging film 9 and the heat-shrinkable film 10 pass through the channel Then it...

Embodiment 2

[0076] This embodiment is optimized on the basis of the above-mentioned embodiment 1.

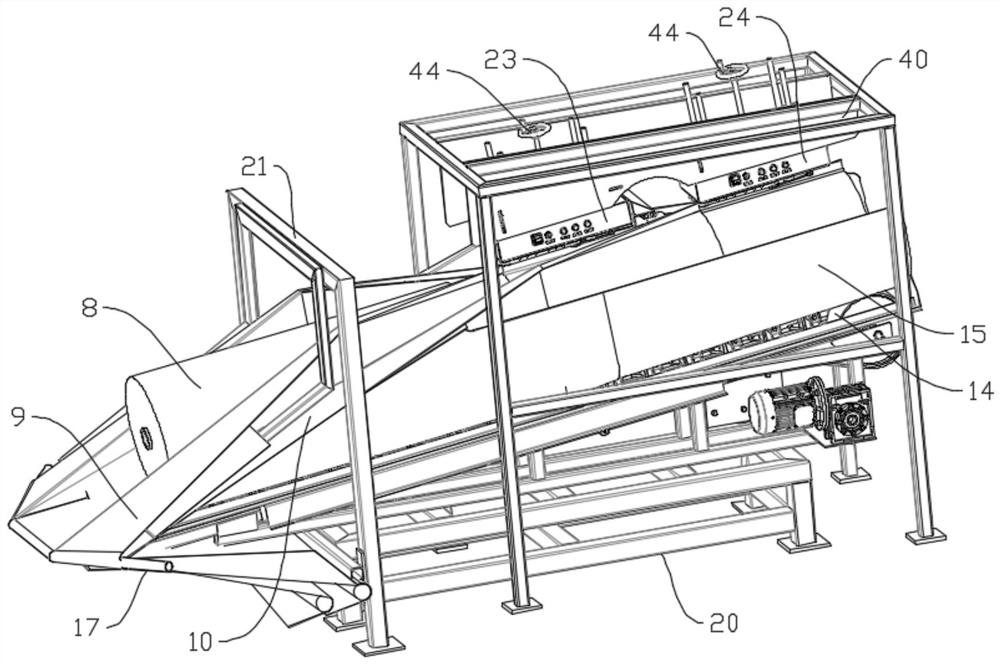

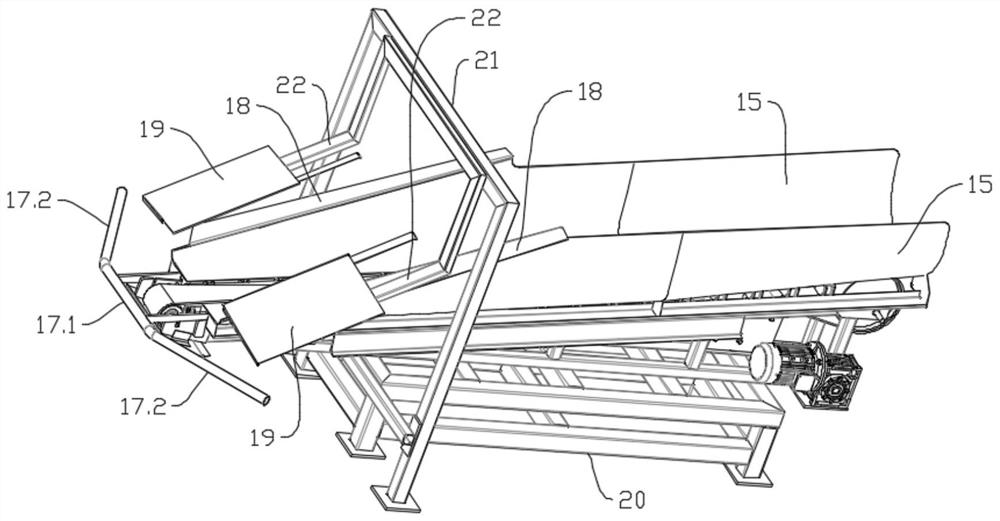

[0077] In order to realize the continuous wrapping and edge sealing treatment of the object to be packaged, the wrapping film wrapping mechanism includes a conveying mechanism 14 and encircling molding shells 15 arranged on both sides of the conveying mechanism 14, and the space enclosed by the wrapping forming shell 15 and the conveying mechanism 14 To encircle the conveying space 16 , the packaging film edge sealing device is located above the encircling conveying space 16 .

[0078] In order to better realize the delivery of the plastic film roll 8, the delivery mechanism 14 is a belt conveyor.

Embodiment 3

[0080] This embodiment is optimized on the basis of the above-mentioned embodiment 2.

[0081] The forming guide mechanism includes a guide bar 17 for introducing the packaging film into the encircling conveying space 16, an inclined guide 18 arranged on the encircling forming shell 15 for guiding the two sides of the heat shrinkable film 10 upward and for separating the inner layer The inclined partition plate 19 of the packaging film 9 and the heat-shrinkable film 10, the inclined partition plate 19 is located above the inclined guide portion 18, and the inclined partition plate 19 and the inclined guide portion 18 are gradually inclined upwards along with the conveying direction of the object to be packaged , the upward inclination of the inclined partition plate 19 is greater than the upward inclination of the inclined guide portion 18 .

[0082] This technical solution mainly realizes the input guidance and wrapping guidance of the packaging film through the cooperation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com