Automatic feeding and water-removing device for chrysanthemum tea processing

An automatic feeding and greening device technology, applied in tea substitutes, loading/unloading, transportation and packaging, etc., can solve problems such as inability to realize streamlined operations, affect the quality of chrysanthemum tea, and different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

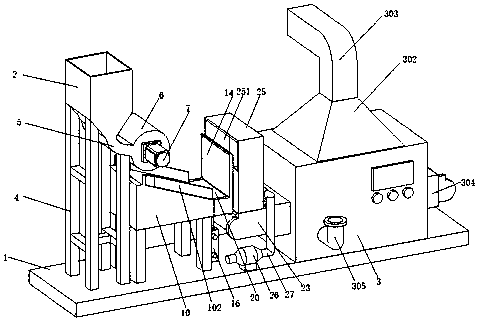

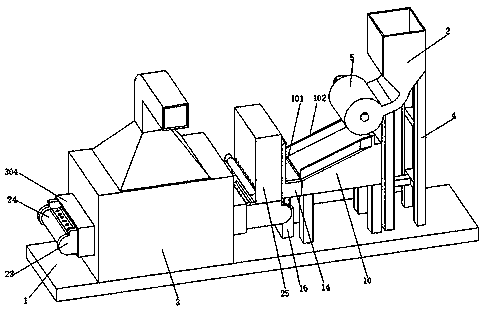

[0037] Embodiment 1 introduces an automatic feeding and greening device for processing chrysanthemum tea, the main structure includes a bottom plate 1, a feeding hopper 2 and a steam box 3.

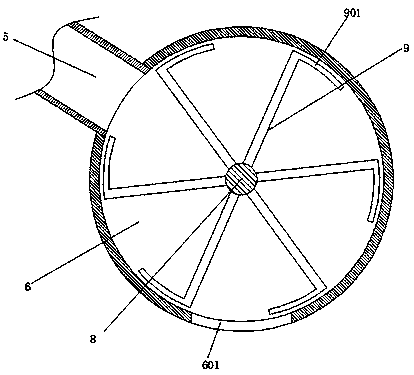

[0038] Reference attached figure 1 And attached figure 2 , a support 4 is provided at the left end of the bottom plate 1, the feeding hopper 2 is fixedly connected to the upper end of the support 4, the lower end of the feeding hopper 4 is connected with a blanking channel 5, and the lower end of the blanking channel 5 is connected with a cylinder 6. Reference attached image 3 , the blanking passage 5 is connected with the upper left end of the cylinder 6, and the lower end of the cylinder 6 is provided with a discharge port 601, and a stepping motor 7 is provided on the front side of the cylinder 6. 60BY350CL-0451 is selected as the input motor 7, the output shaft of the stepper motor 7 extends into the inner cavity of the cylinder 6, and a rotating shaft 8 is connected to its end, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com