Spring type automatic cable winding and unwinding device

An automatic cable, retractable device technology, applied in the field of spring-type automatic cable retraction device, can solve the problems of increasing the labor intensity of operators, poor retraction effect, cable wear, etc., to eliminate electric shock safety hazards, automatic retraction Good effect, avoid the effect of touching the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

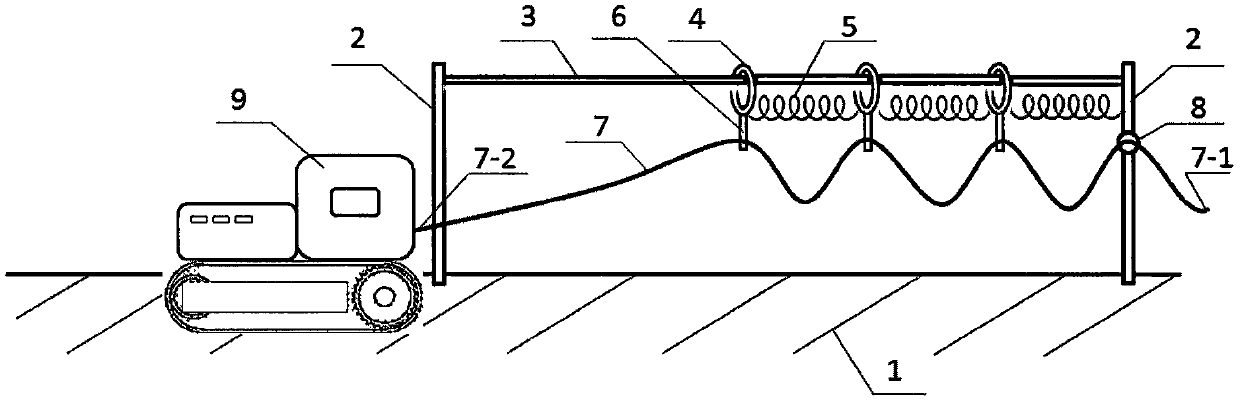

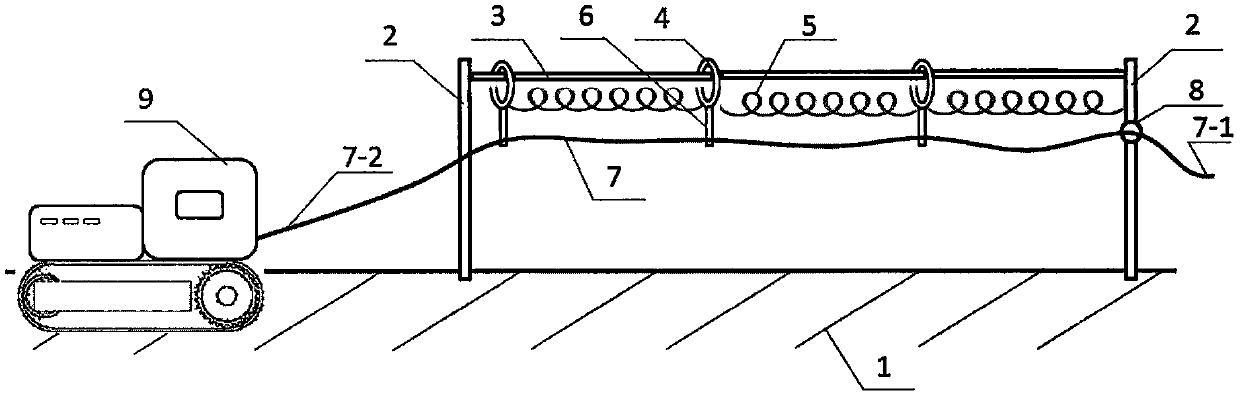

[0020] Refer to attached figure 1 with 2 , a spring-type automatic cable retracting device, including a bracket 2, a sliding rod 3, a slip ring 4, a spring 5, a cable clamp 6, a cable 7, a splint 8 and a mobile electromechanical device 9; it is characterized in that: two brackets 2 are respectively Fix it on the ground 1, install a sliding rod 3 between two brackets 2, set multiple slip rings 4 on the sliding rod 3, install a cable clamp 6 at the lower end of each slip ring 4, and connect one end 7-1 of the cable 7 to the AC For power supply, fix the splint 8 on the bracket 2 on the side adjacent to the cable terminal 7-1, fix the cable 7 with the splint 8, and install the springs 5 sequentially between the bracket 2 on the side adjacent to the cable terminal 7-1 and each slip ring 4 , use the cable clamps 6 under the slip ring 4 to clamp the cables 7 respectively, and ensure that the cable length between two adjacent cable clamps 6 is not less than the length of each sprin...

Embodiment 2

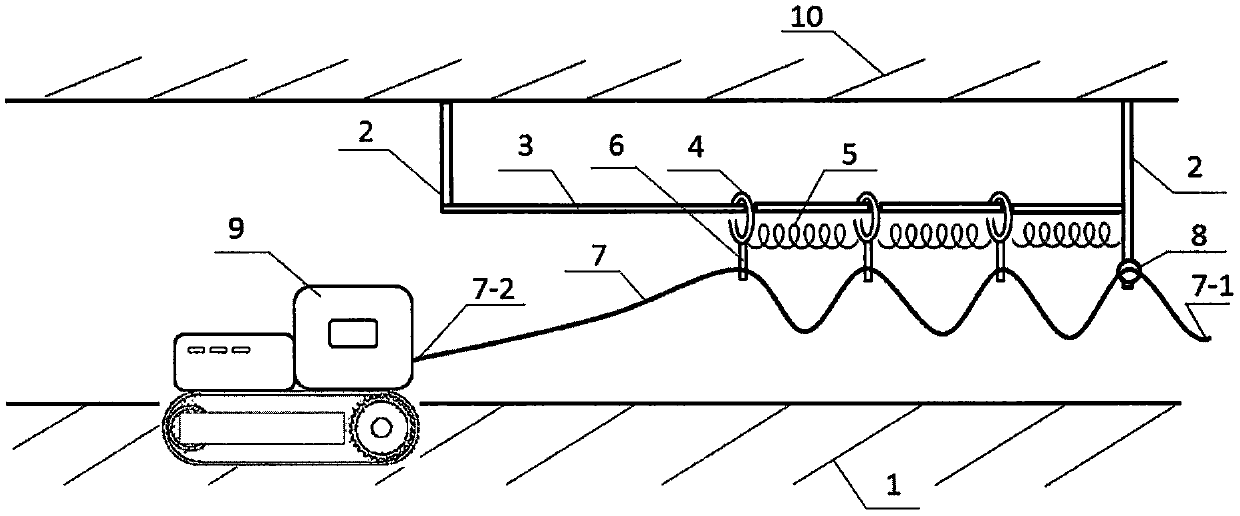

[0024] Refer to attached image 3 , in order to save ground space, the bracket 2 in the first embodiment is fixed on the top of the mine or tunnel.

Embodiment 3

[0026] For the convenience of installation, the bracket 2 in the first embodiment is fixed on the wall of the tunnel, and the sliding rod 3 is replaced with a steel wire rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com