Hoisting device and control method suitable for four-point hoisting of precast tubular pile

A technology of prefabricated pipe piles and lifting devices, applied in transportation and packaging, load hanging components, construction, etc., can solve the problems of huge temporary hoisting facilities, failure to maintain stable vertical pipe piles, and large local stress of pipe piles, etc., to achieve Ensure verticality, ensure safety, and reduce the effect of local force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

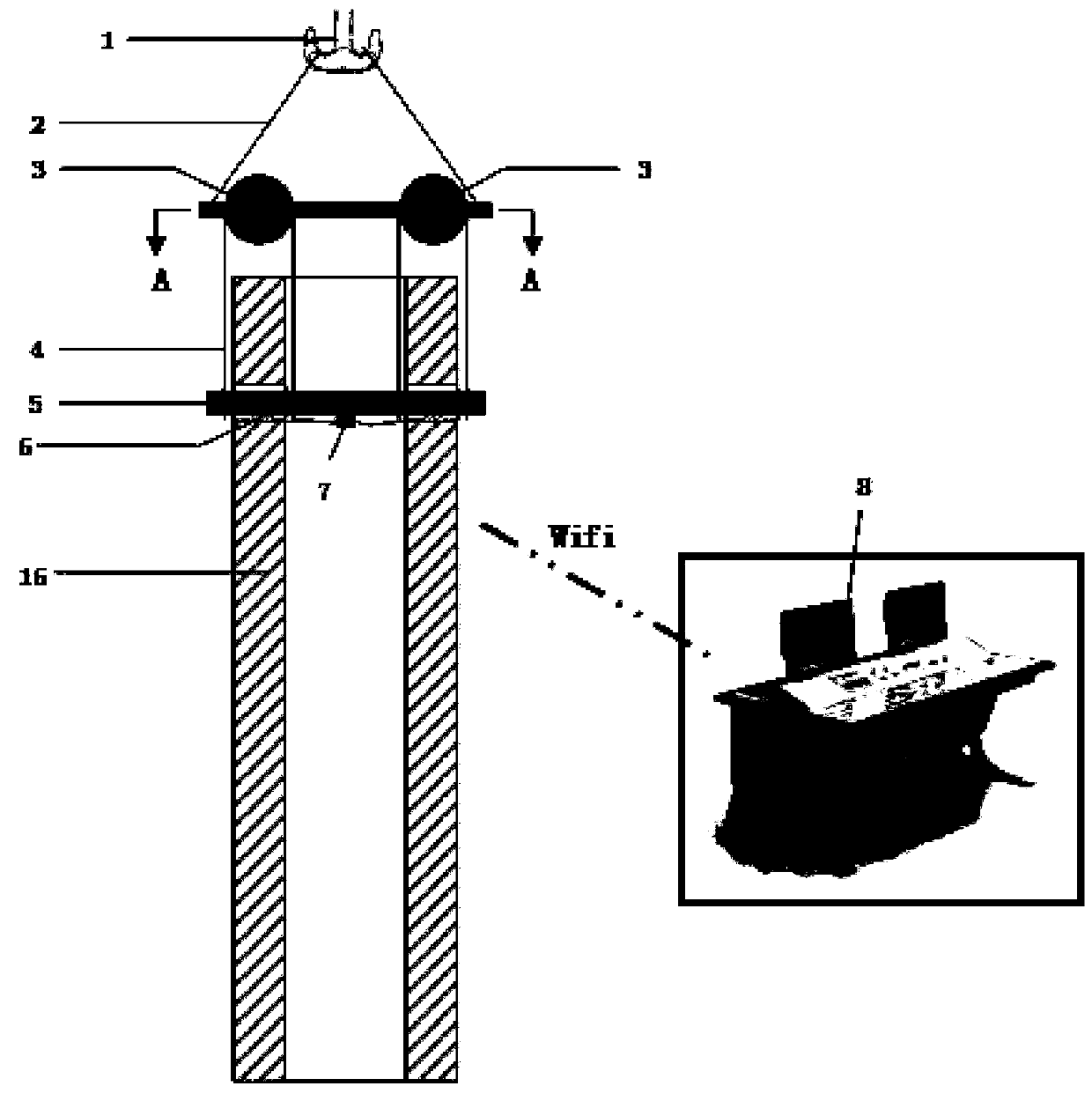

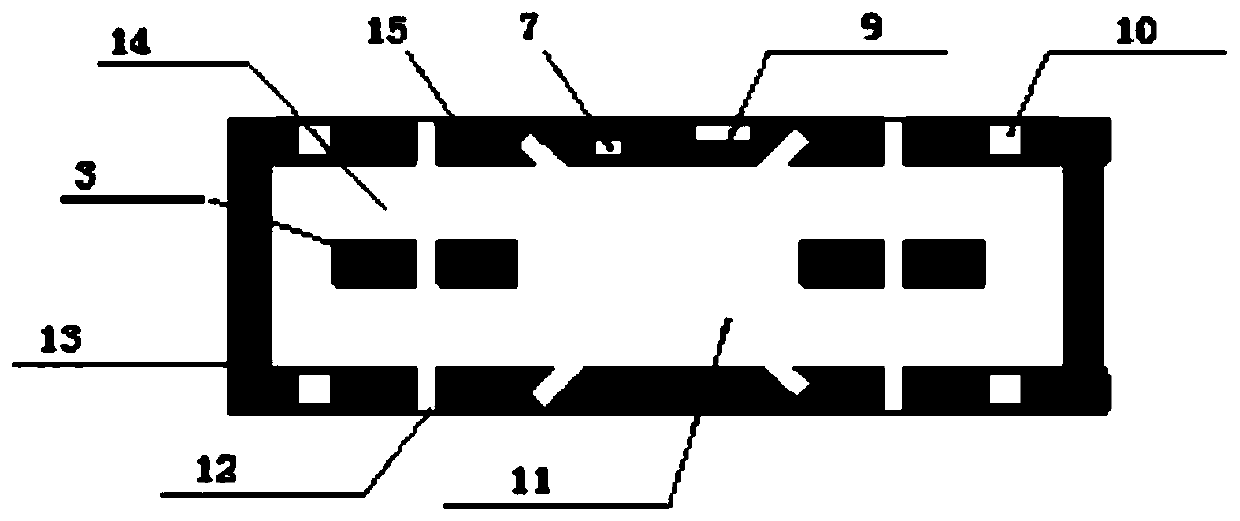

[0029] See Figure 1-Figure 2 In a preferred embodiment of the present invention, a lifting device suitable for four-point lifting of prefabricated pipe piles is designed based on the following prefabricated pipe pile 16: one end of the prefabricated pipe pile 16 is provided with a transverse penetration The reserved hole on the pipe wall, the axial direction of the reserved hole is perpendicular to the length direction of the prefabricated pipe pile 16.

[0030] The lifting device includes a steel frame 14, four slings 2, four slings 4, a steel bar 5 and a control system. The four corners of the top of the steel frame 14 are each fixed to one end of a sling 2, the other end of the sling 2 is used to connect the crane hook 1, and the middle of the steel frame 14 is installed with two fixed pulleys 3, two The axles 12 of the fixed pulley 3 are arranged in parallel, and each fixed pulley 3 is equipped with a sling 4, the two ends of the sling 4 are respectively connected to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com