Filling machine with constant liquid level

A filling machine and liquid level technology, which is applied in liquid bottling, packaging, bottle filling, etc., can solve problems such as increased volume, bottle mouth contamination, and reduced volume, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

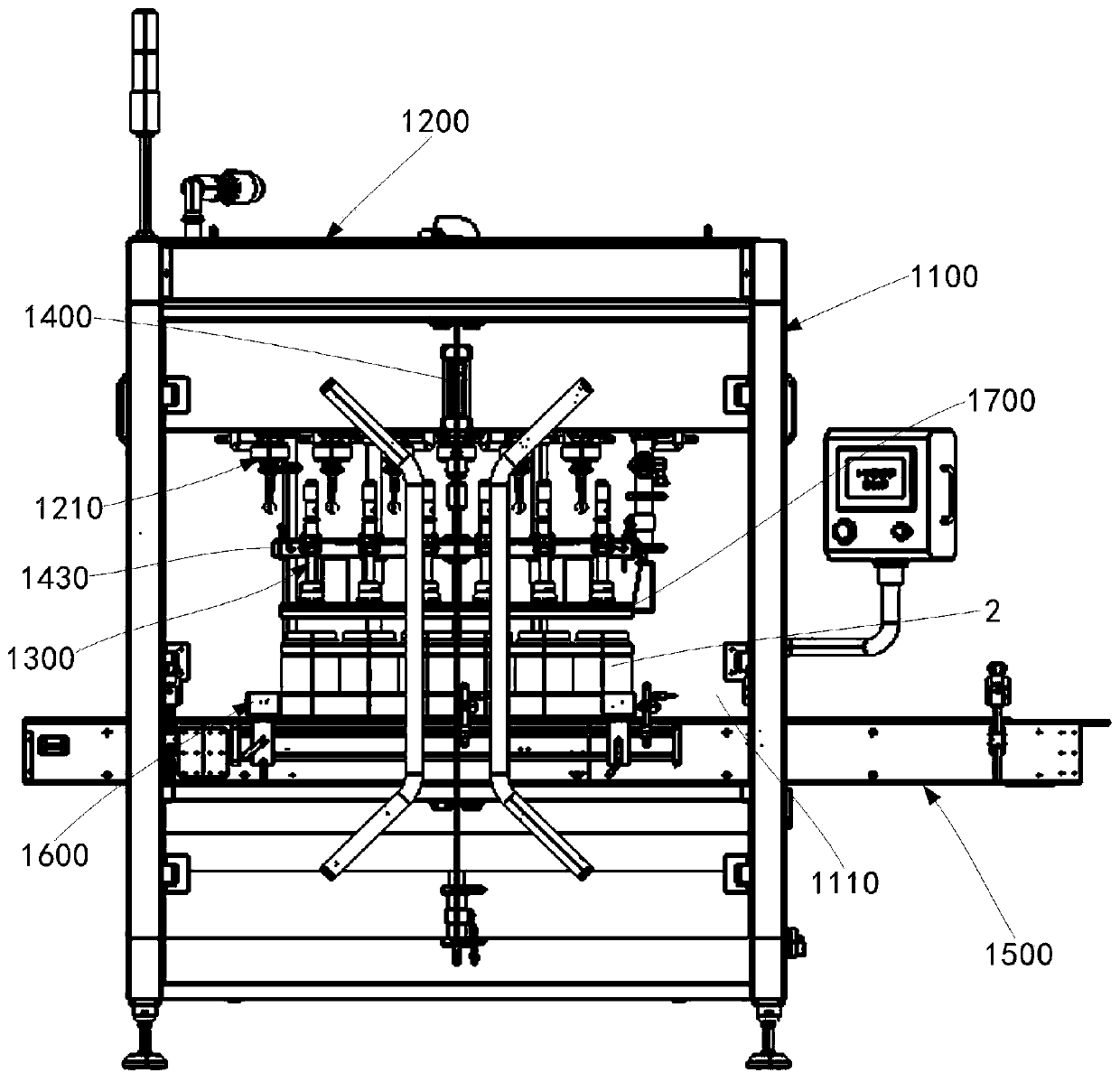

[0031] Such as figure 1 As shown, a liquid-level filling machine includes a cabinet 1100, a high-level liquid silo 1200, a filling head 1300, a first lifting mechanism 1400, a conveyor belt 1500, and a bottle blocking and releasing mechanism 1600.

[0032] Such as figure 1 As shown, the front side of the cabinet 1100 has a glass cabinet door 1110 .

[0033] Such as figure 1 As shown, the high-level liquid silo 1200 is arranged on the upper side of the cabinet 1100 , and is connected to the filling head 1300 through the liquid outlet regulating valve 1210 , so as to discharge materials to the filling head 1300 .

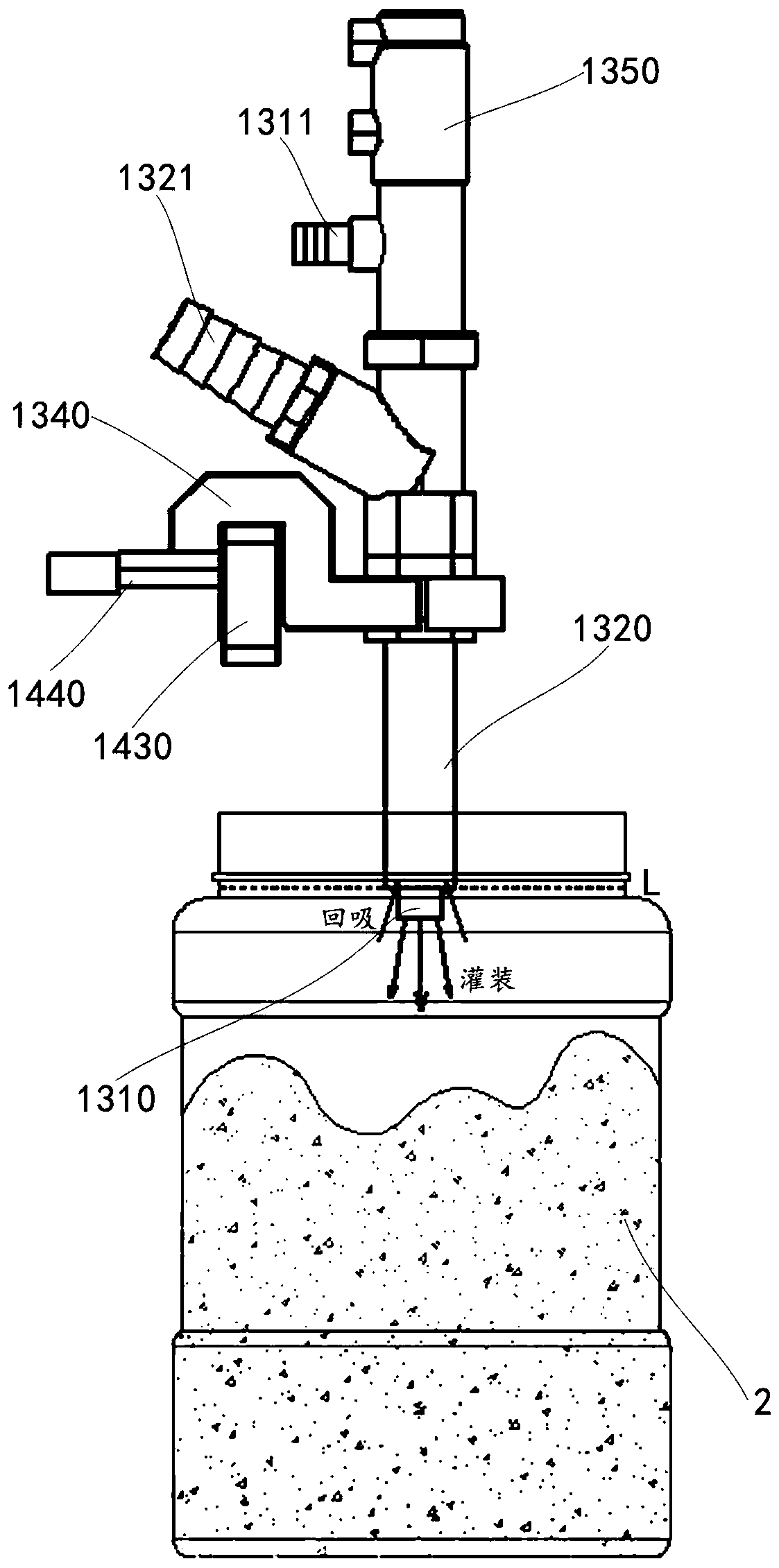

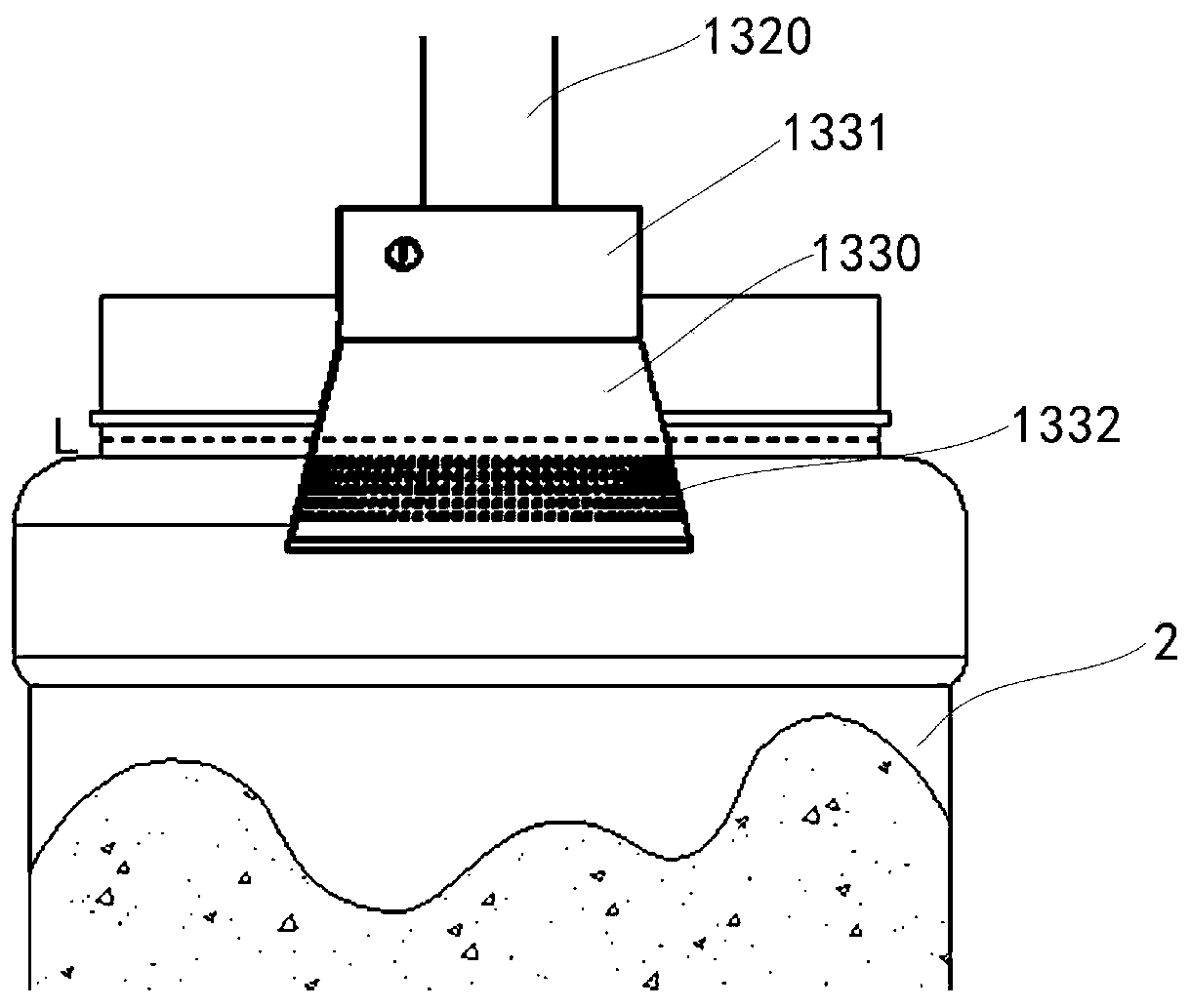

[0034] Such as figure 2 As shown, the filling head 1300 includes a vertically arranged filling pipe 1310 and a suction pipe 1320. The filling pipe 1310 is connected to the liquid outlet regulating valve 1210 through a connecting pipe, thereby connecting to the high-level liquid silo 1200. The suction pipe 1320 is connected to the suction pipe 1320. The suction pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com