Scraper-adjustable sewage treatment air floatation unit

A sewage treatment, adjustable technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the cost of sewage treatment, occupying an area, and less separation time , less scum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

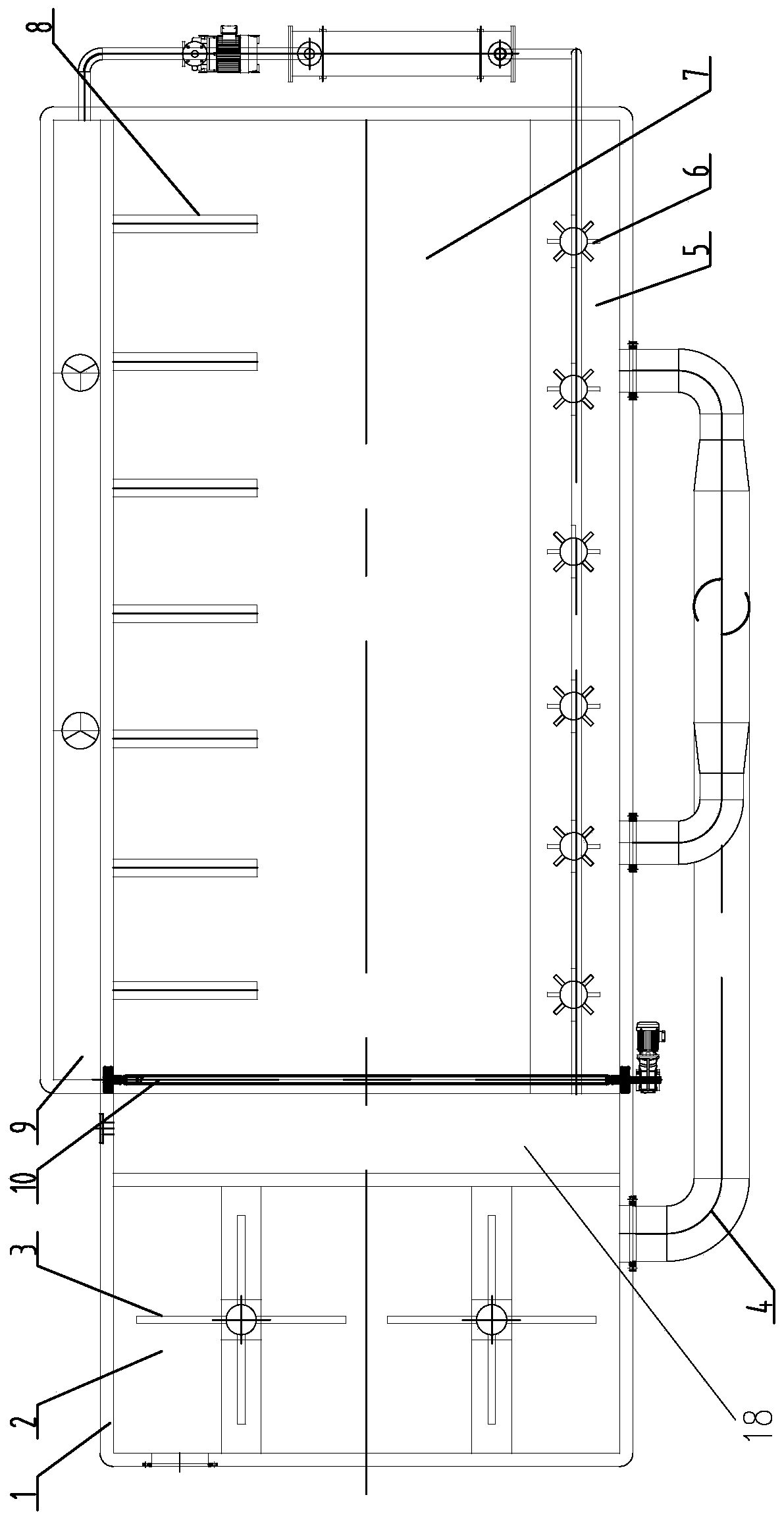

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

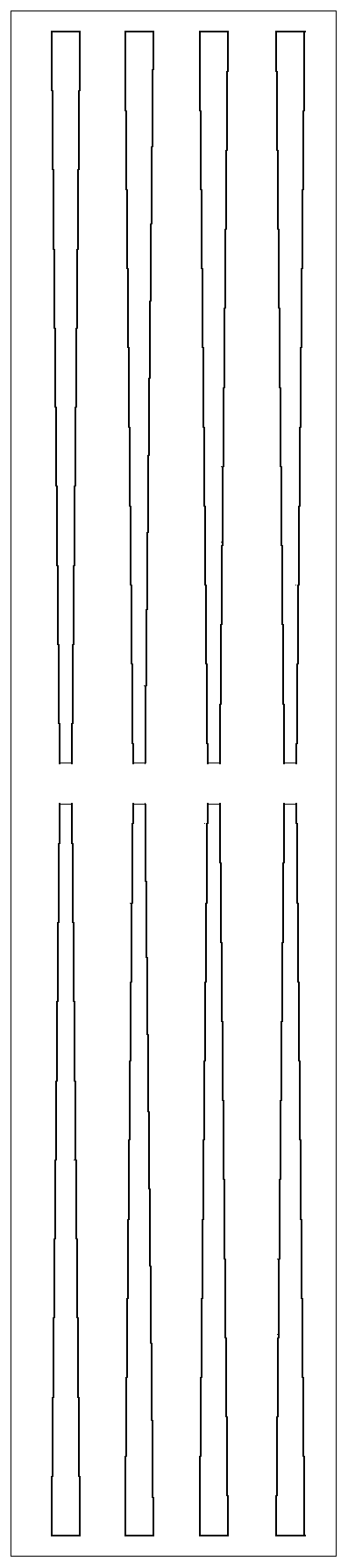

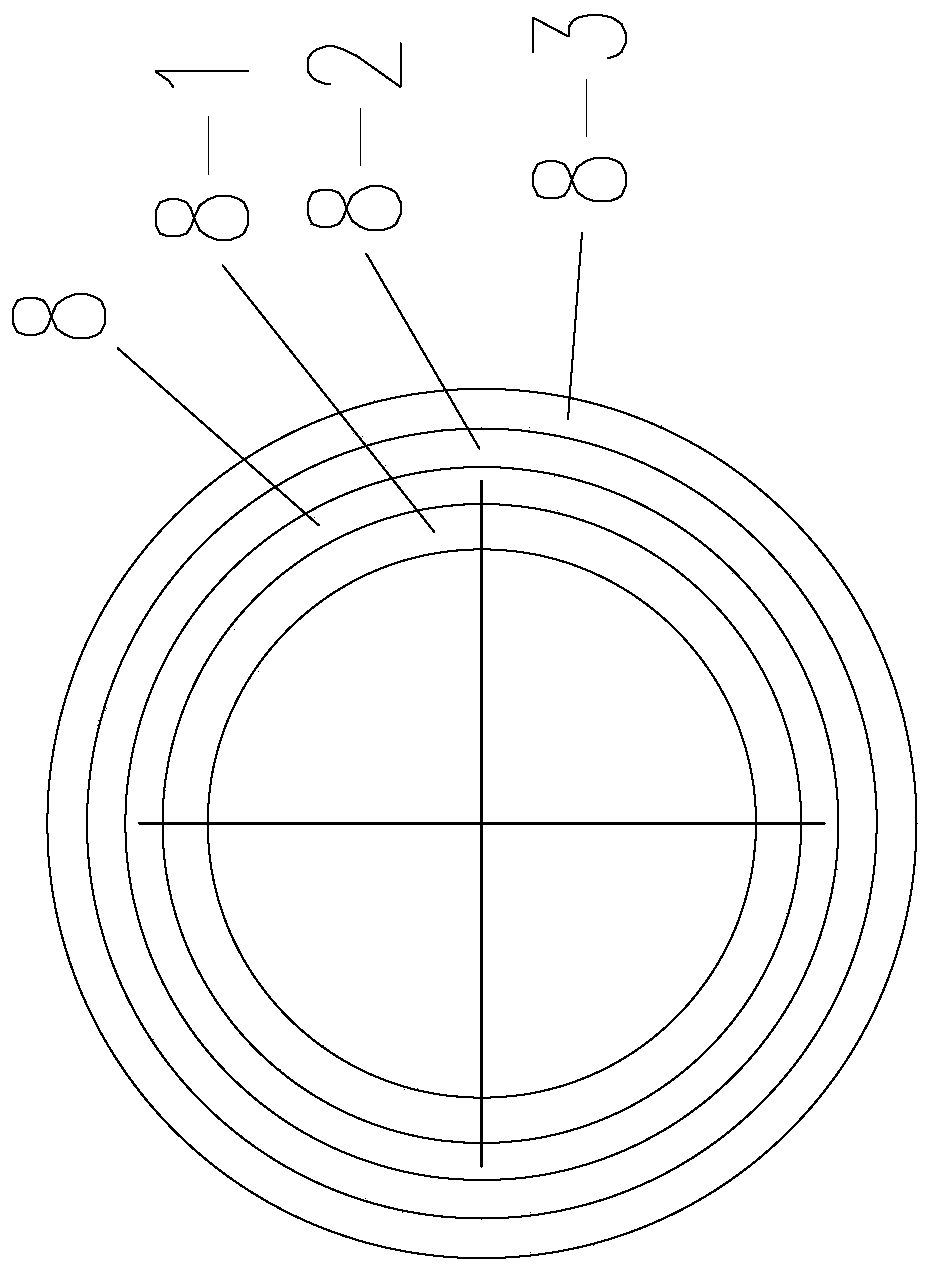

[0023] Figure 1-6 Including tank body 1, fast and slow mixing tank 2, stirring device 3, sewage pipe 4, contact chamber 5, releaser 6, separation chamber 7, clear water collection pipe 8, spiral rib 8-1, sound insulation layer 8-2, Shock absorbing layer 8-3, clean water tank 9, slag scraping mechanism 10, drive reducer 11, bearing seat 12, drive shaft 13, fixed plate 14, adjustment plate 15, rigid scraper 16, flexible scraper 17, scum tank 18. Connecting shaft 19, adjustable stirring shaft 20, stirring paddle 21, coupling 22, slag separating plate 23, transition sloping plate 23-1, scum 24, liquid level 25, etc.

[0024] Such as figure 1 , Figure 5 As shown, the present invention is an air flotation unit for sewage treatment with adjustable scraper, comprising a tank body 1, the left side of the tank body 1 is a fast and slow mixing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com