Cast-in-situ aqueduct curing device and construction method

A construction method and technology of aqueducts, applied in artificial waterways, manufacturing tools, water conservancy projects, etc., can solve problems such as low construction efficiency, large tank inner wall size, uneven artificial water spraying maintenance, etc., to reduce the impact of wind, pressure The effect of high membrane efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

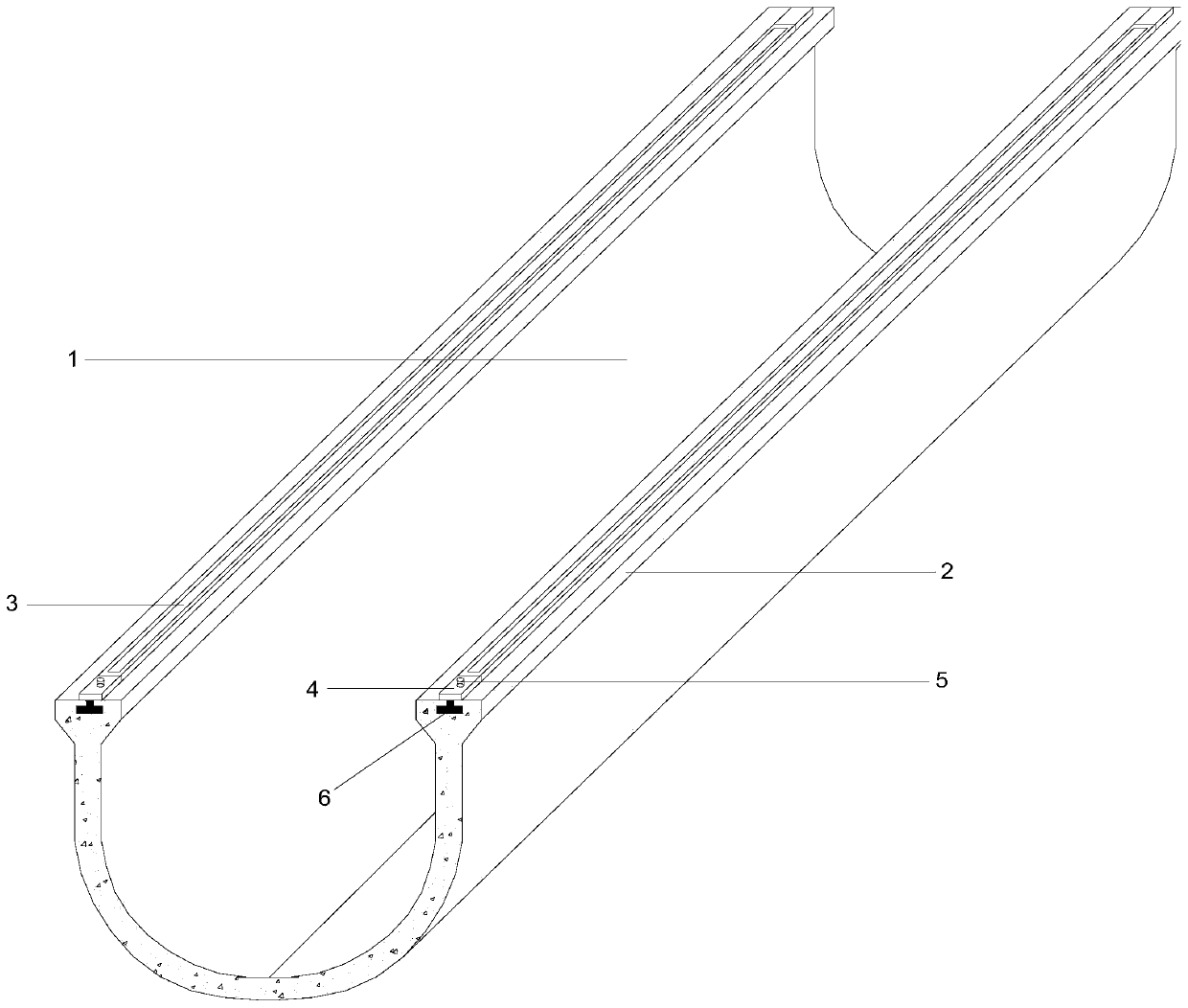

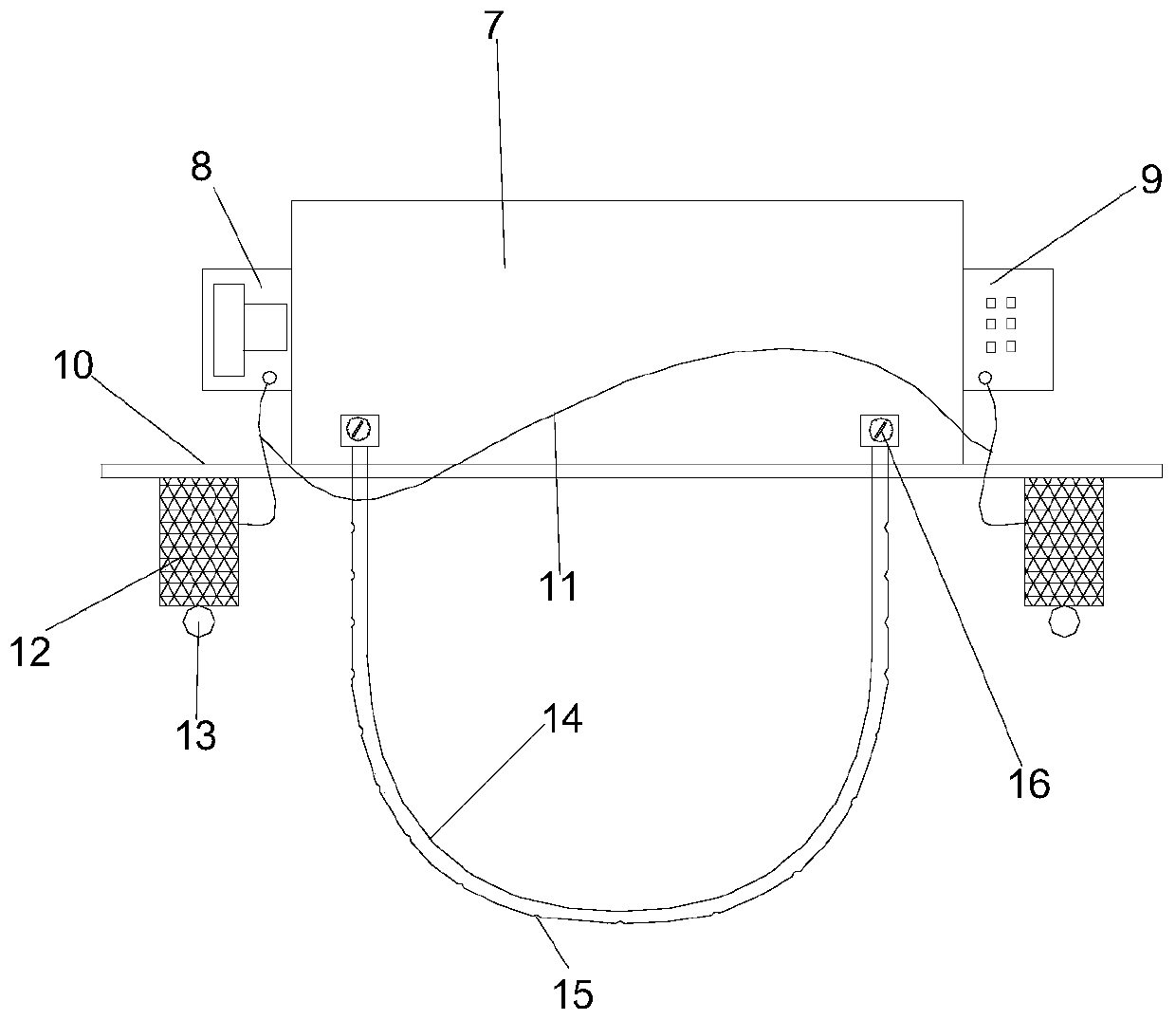

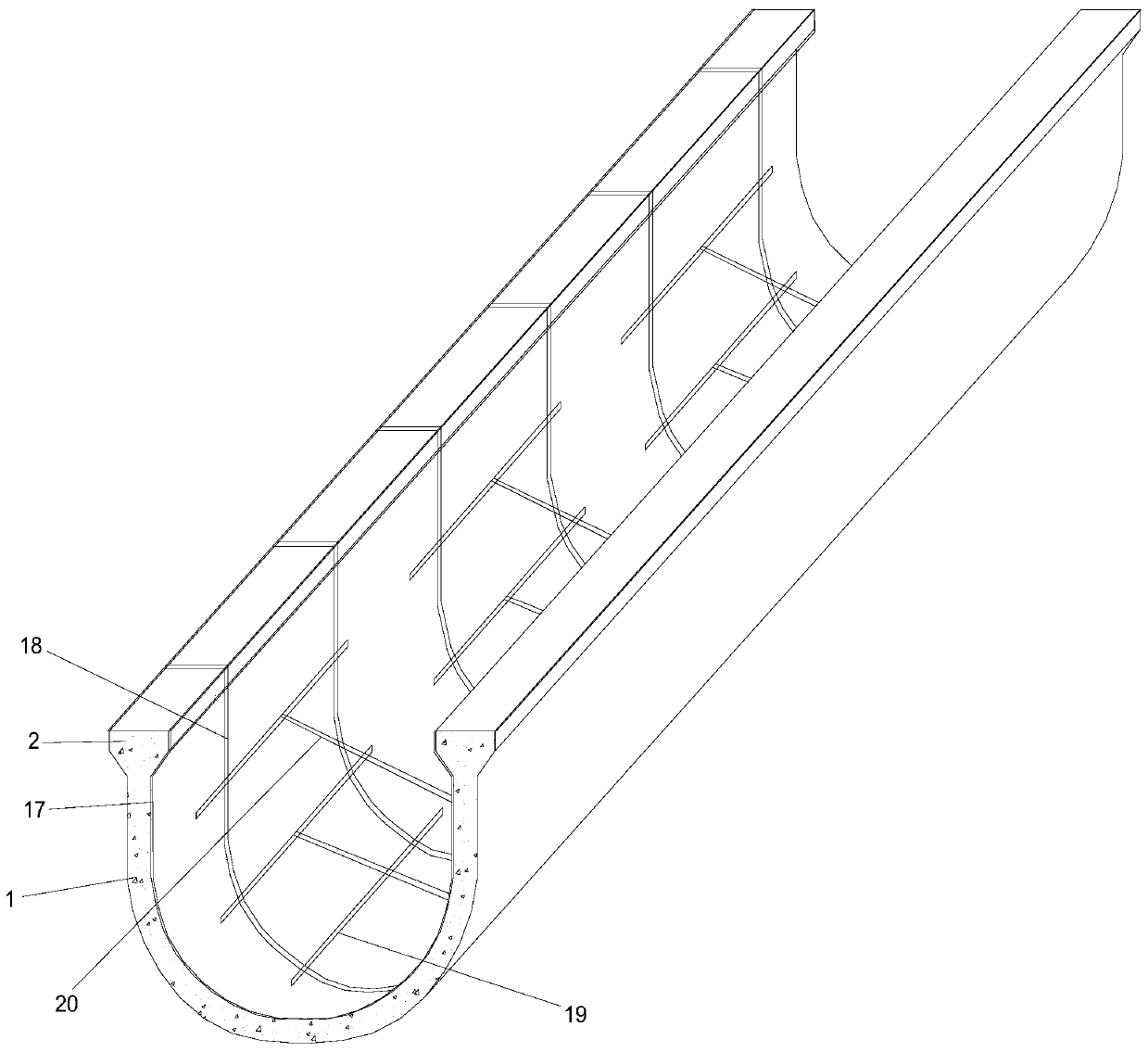

[0037] Embodiment 1: as Figure 1-5 As shown, in order to solve the above problems, the embodiment of the present invention provides a cast-in-place aqueduct maintenance device and construction method thereof, the device is arranged on the tank cap 2 of the aqueduct, and is applied to the tank inner wall 1 of the aqueduct for water spray maintenance, The slot cap 2 is provided with a slide rail 3, the slide rail 3 is made of a steel plate, and the slide rail 3 is slidably provided with a spray maintenance device, wherein the spray maintenance device includes a bottom plate 10, and the bottom plate 10 is supported on a support end 12, and the support A pulley 13 is provided at the bottom of the end 12. The outer peripheral surface of the pulley 13 is adapted to the slide rail 3 and can be guided by the slide rail 3 and slide along the slide rail 3. A driving motor 8 is arranged on the upper side of the bottom plate 10, and the pulley 13 is communicatively connected to the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com