Horizontal directional cohesionless soil sampling drilling tool used for unconsolidated fractured formation

A horizontally oriented, non-adhesive technology, applied in directional drilling, earth square drilling, sampling devices, etc., can solve the problems of inconvenient pulling out, inconvenient disassembly, and laborious, etc., to reduce disturbance, avoid falling off, and reduce soil sample drop The effect of falling chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

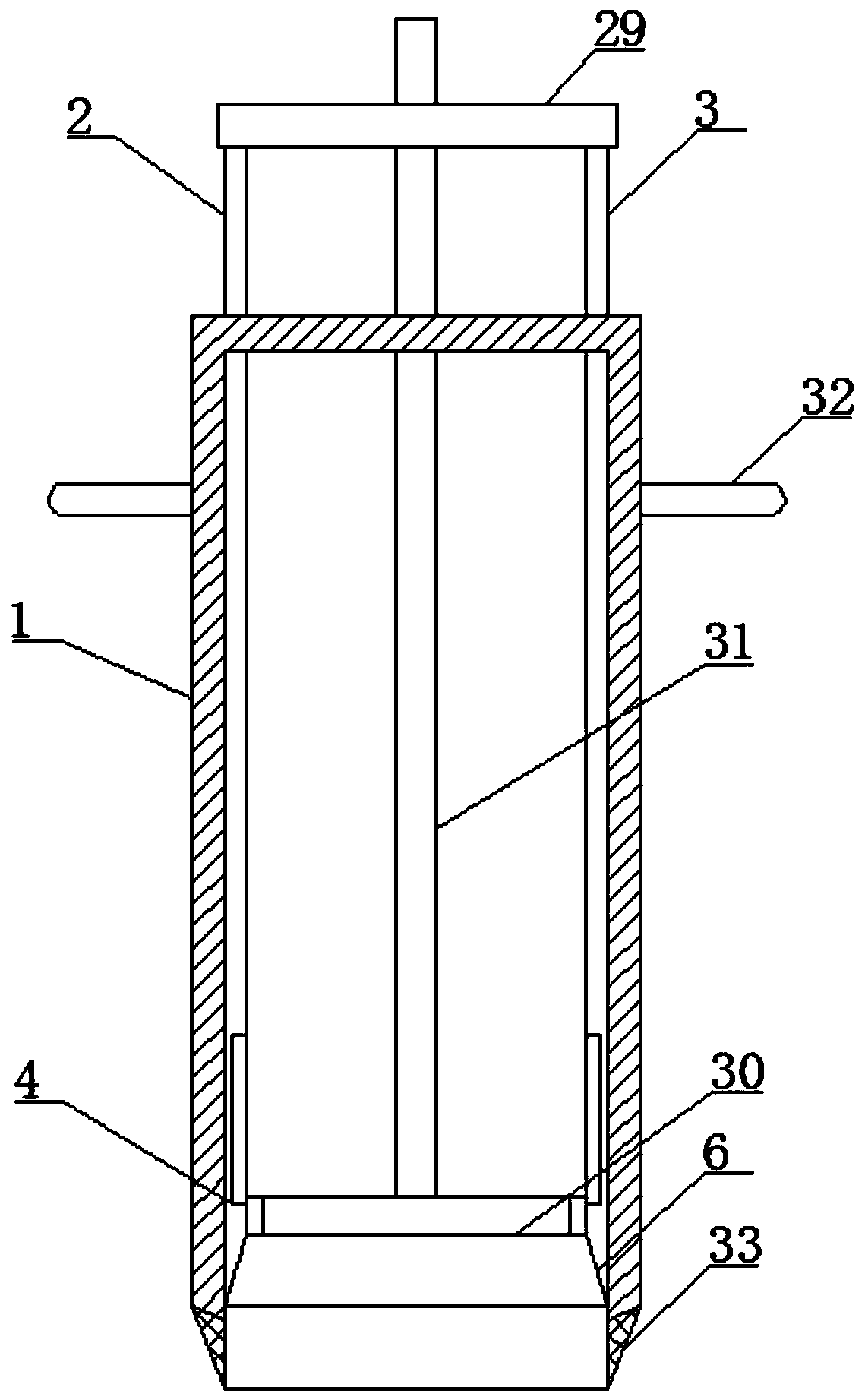

[0047] Such as Figure 1-8 As shown, the horizontally oriented non-cohesive soil sampling drilling tool for loose and broken formations according to the embodiment of the present invention includes a cylinder body 1 and a core pipe-2 and a core pipe arranged symmetrically in the cylinder body 1 Two 3, the core tube 1 2 and the core tube 2 3 are both semi-cylindrical structures, and the bottom ends of the core tube 2 and the core tube 2 3 are close to each other. A side slot 4 is provided, and a closing mechanism 5 is provided in the side slot 4. Through the setting of the closing mechanism 5, the arc-shaped baffle 18 is connected with the core tube 1 2 and the core tube 2 3 under the action of the block 23. The inner wall of the inner wall remains consistent and is on the same plane. After the coring is completed, press the backing plate 27 to move the block 23 downward and separate from the groove 21 of the arc-shaped baffle 18, and the arc-shaped baffle 18 is separated from ...

Embodiment 2

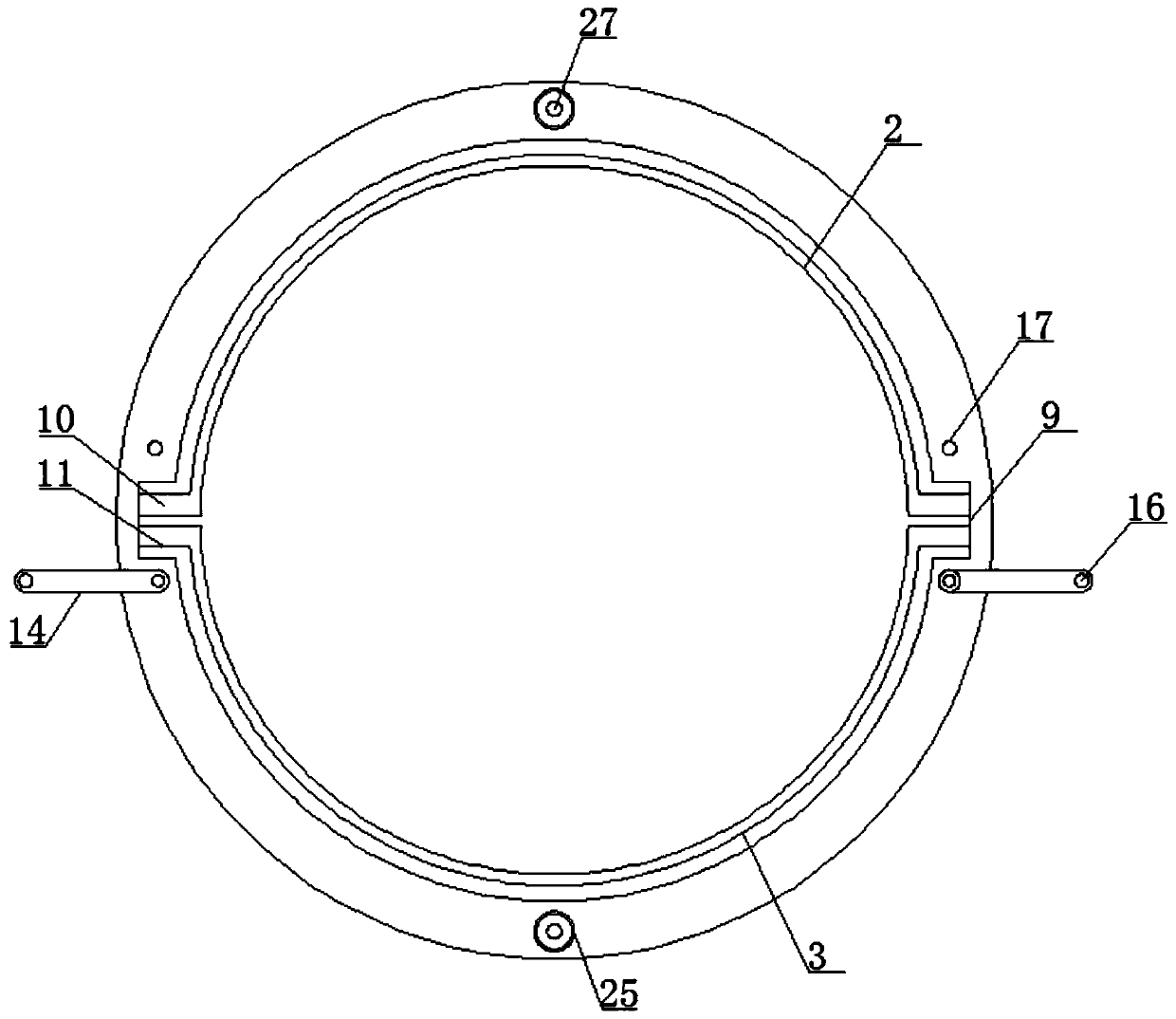

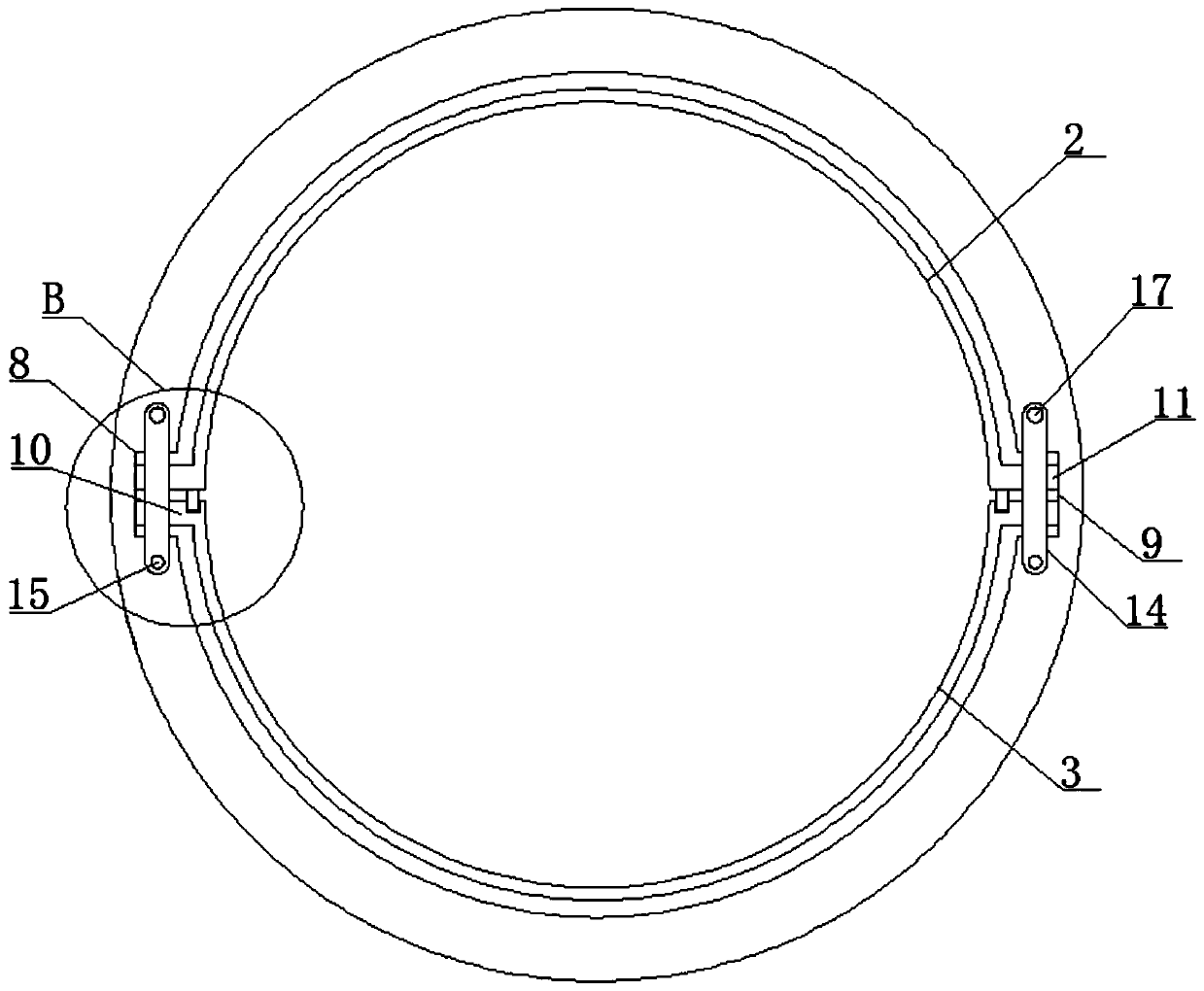

[0049] Such as Figure 1-3 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the first limiting groove 8 and the second limiting groove 9 are arranged symmetrically on both sides of the cylinder body 1, and the first core tube 2 Both sides of the core tube two 3 are symmetrically provided with a fixed block one 10 and a fixed block two 11 matched with the limit slot one 8 and the two limit slot 9, and the core tube one 2 With the cooperation of the core tube two 3 and the limit groove one 8 and the limit groove two 9, the core tube one 2 and the core tube two 3 are combined to form a cylindrical structure, and the fixed block one 10 and the fixed block The second 11 is aligned with the limiting groove one 8 and the second limiting groove 9, and then inserted into the cylinder body 1, so that the core tube one 2 and the core tube two 3 are installed in the cylinder body 1, and after the sampling is completed, By pulling out th...

Embodiment 3

[0052] Such as Figure 1-3 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the side of the core tube one 2 close to the core tube two 3 is provided with a bump 12, the One side of the core tube two 3 is provided with a fixed groove 13 matching the protrusion 12, and the top end of the core tube one 2 is located on one side of the limit groove one 8 and the limit groove two 9 All are provided with movable bar 14, and described movable bar 14 is connected with described coring tube one 2 by fixed shaft 15, and the other side of described movable bar 14 extends to the top of described coring tube two 3 and is provided with fixing. Hole 16, described fixing hole 16 is provided with the fixing bolt 17 that is connected with described coring tube two 3, by the setting of movable bar 14, the bottom of movable bar 14 is blocked stop-stop groove one 8 and stop-stop groove two 9. Make the fixed block 10 and the fixed block 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap