Easy-to-install hydraulic hose connector for engineering machinery

A technology of hydraulic pipe joints and construction machinery, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, hose connection devices, etc., which can solve the problems of delay in construction period, inability to change the length, waste, etc., to save costs and improve piping efficiency , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

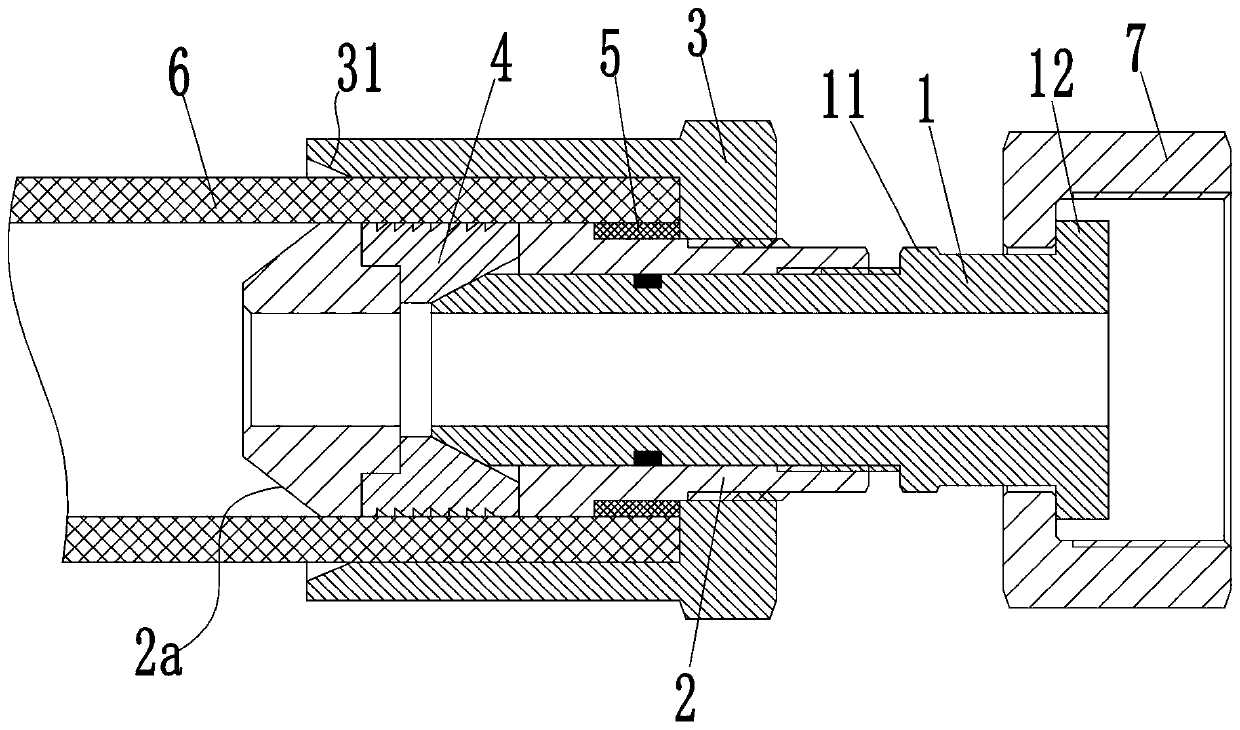

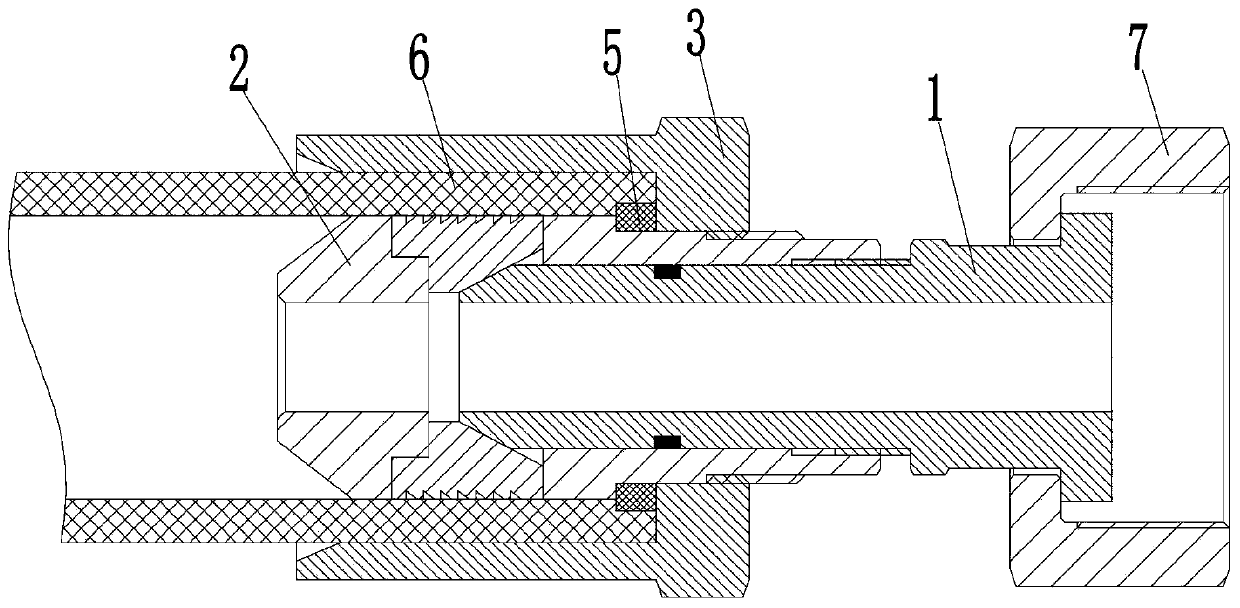

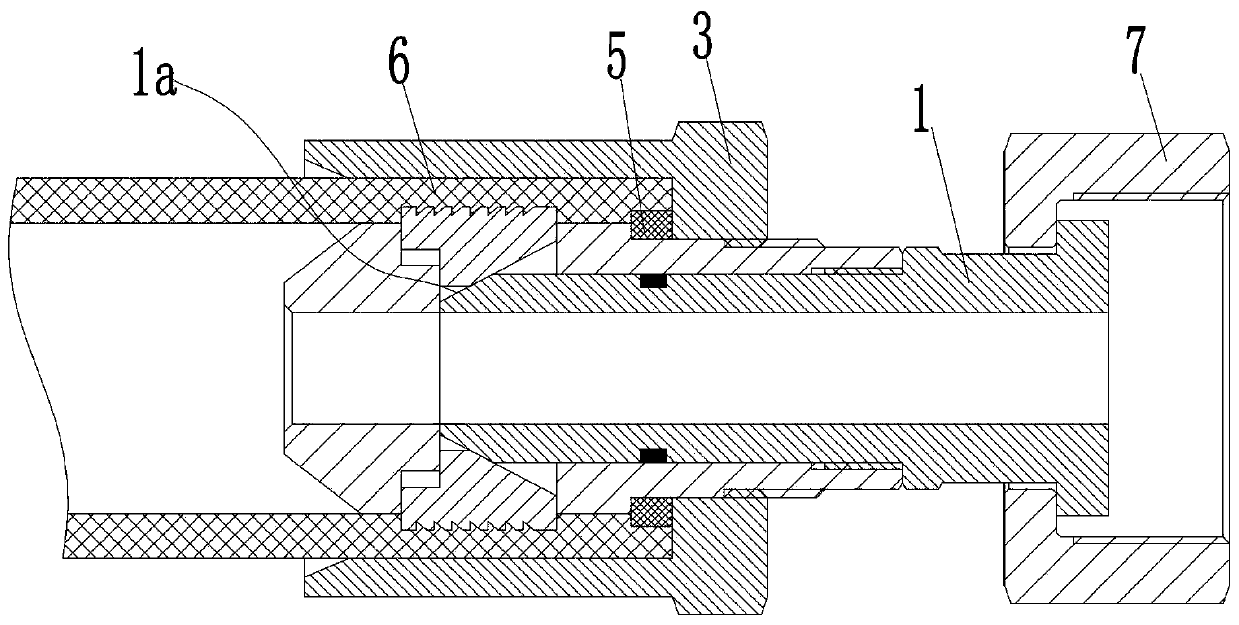

[0027] see Figure 1-4 As shown, an easy-to-install hydraulic pipe joint for engineering machinery includes an inner casing 2, and the inner casing 2 is threaded with a joint jacket 3 on the outer circumference side near the right end, and the joint jacket 3 and the inner casing 2 An annular intubation groove 201 is formed between them; the inner casing 2 is sleeved with a sealing ring 5 made of rubber material near the outer circumferential side of the joint jacket 3, and the joint jacket 3 is along the axis of the inner casing 2. When moving to the left, the extrusion sealing ring 5 protrudes outwards. The inner side wall of the inner sleeve 2 is provided with an annular cutout 21, and a plurality of notches 22 are evenly spaced along the circumferential direction on the side wall of the inner sleeve 2, and the notch 22 is connected with the intubation groove 201. It communicates with the annular groove 21, and the notch 22 is located at the left end of the annular groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com