Automatic pipe routing machine for assembling radiators

A radiator and pipe laying machine technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as scratches, leakage and deformation of heat pipes, and achieve the effect of balancing the force on pipes and avoiding deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

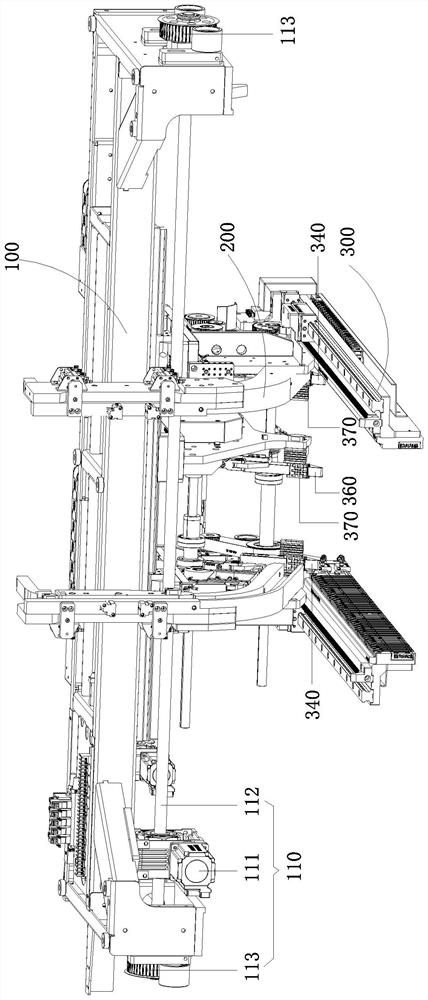

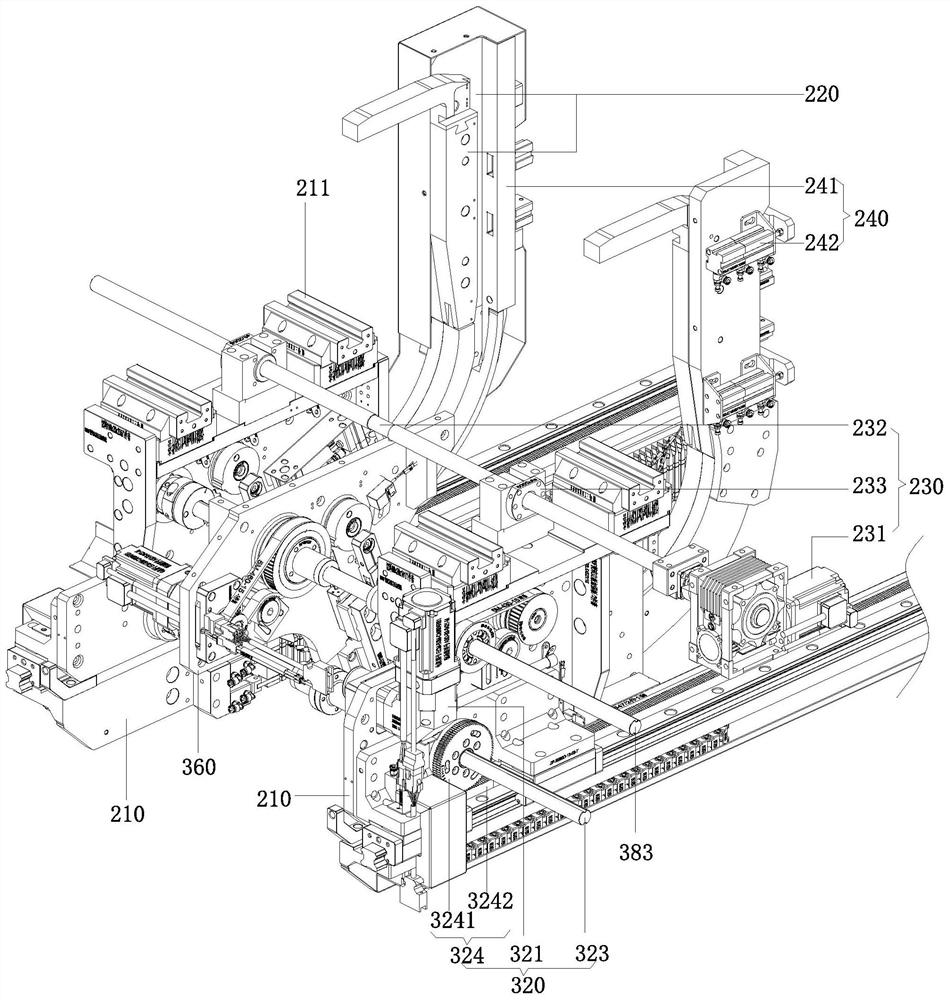

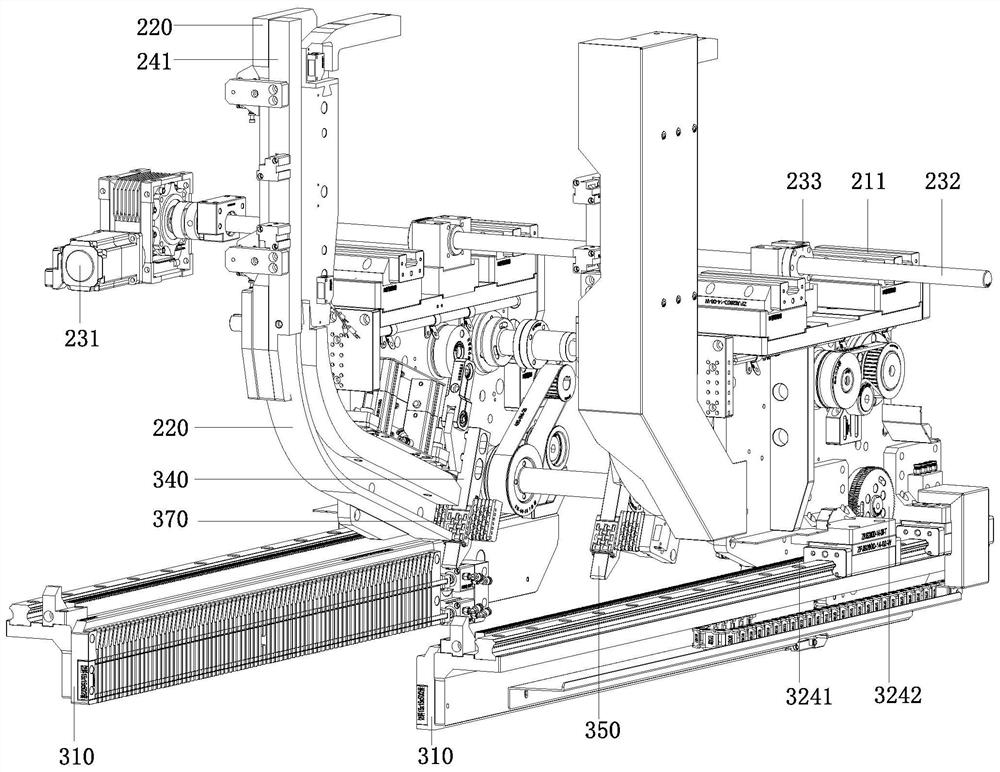

[0039] Please refer to Figure 1-Figure 4 As shown, the present invention discloses an automatic pipe layout machine for assembling a radiator, including a mobile frame 100 , a pipe storage mechanism 200 and a pipe layout mechanism 300 .

[0040] Please refer to figure 1 and figure 2 As shown, the tube storage mechanism 200 includes a pair of tube storage base plates 210 , a pair of tube grooves 220 , a second drive unit 230 and a tube width adjustment unit 240 .

[0041] A pair of tube storage base plates 210 are slidably installed on the mobile rack 100 along the length direction of the heat dissipation pipes through the linear sliding table 211 . The second driving unit 230 drives the pair of tube stocker base plates 210 to move toward each other or in the opposite direction. A pair of pipe grooves 220 are installed on the pipe base plate 210 one by one, so that the pipe layout requirements of heat pipes of different lengths and specifications can be met.

[0042] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com