A detonator automatic production line automatic mold transfer equipment

An automatic production line and automatic technology, applied in the direction of detonators, offensive equipment, etc., can solve the problems of high manual labor intensity, large number of mold liners, hidden safety hazards, etc., and achieve the reduction of manual operation process, improve the efficiency of pipe arrangement, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

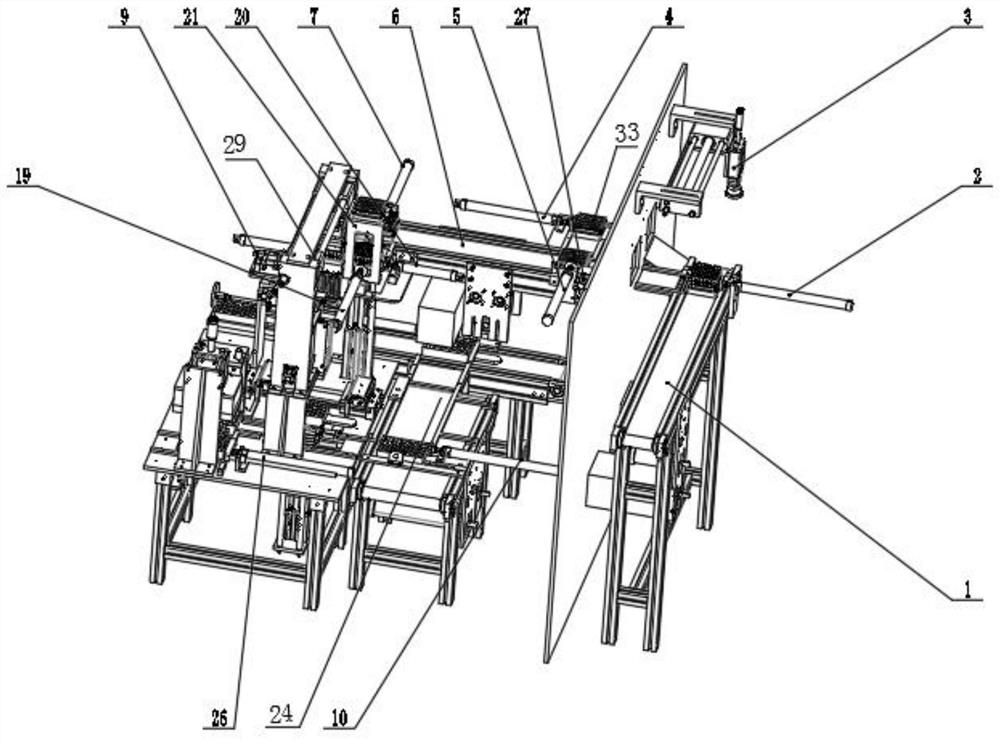

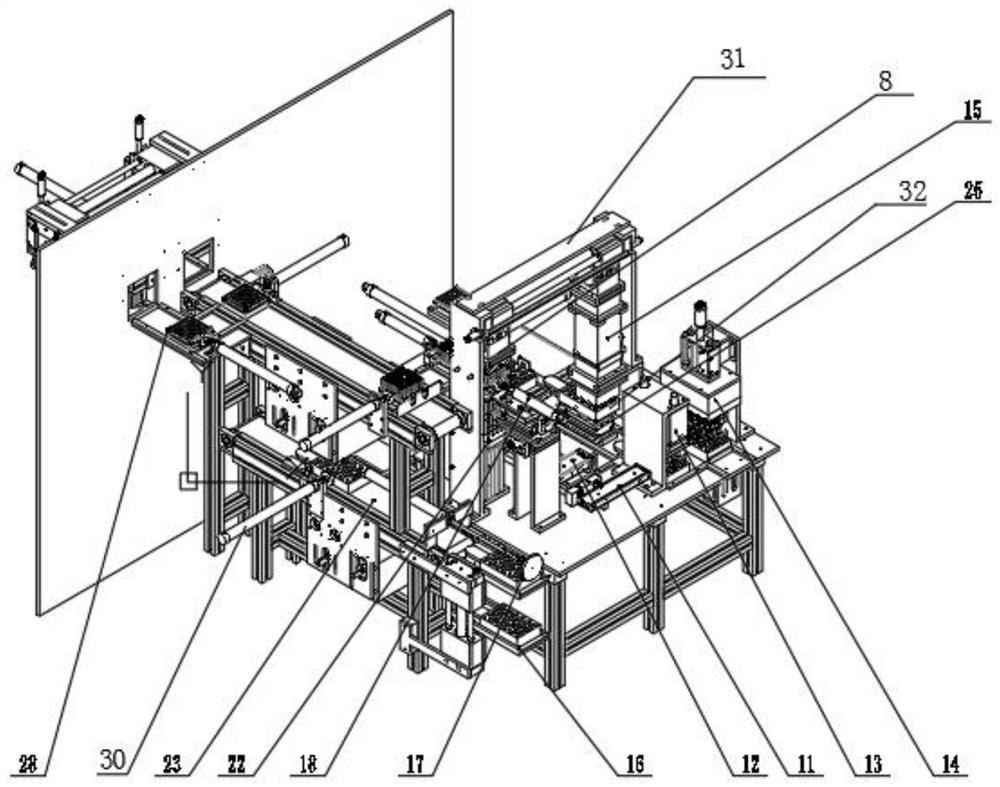

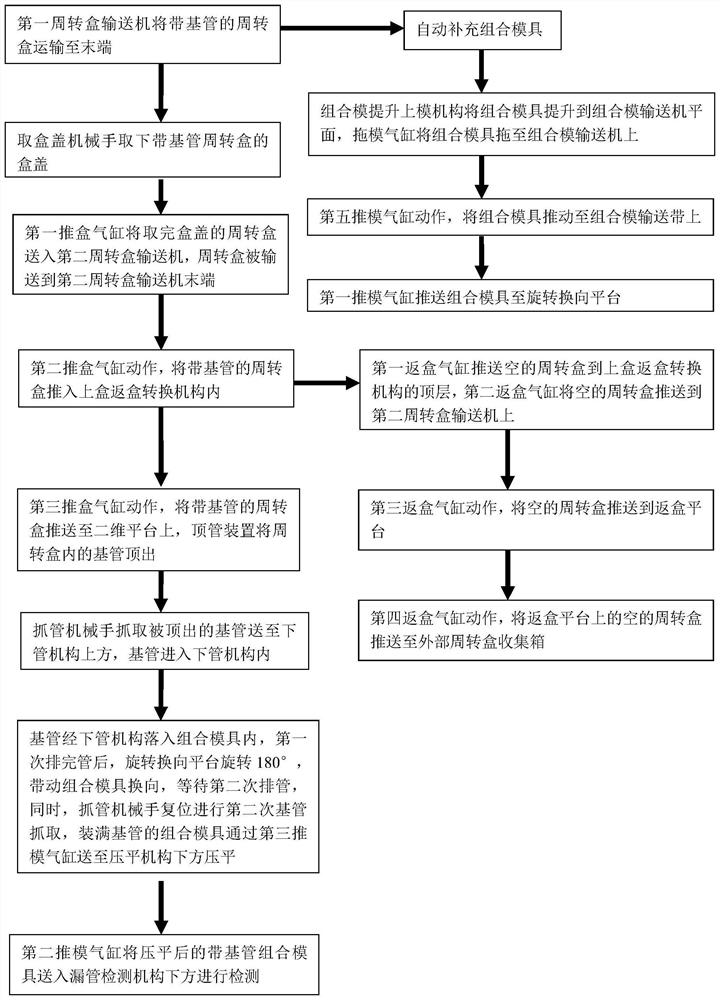

[0049] like figure 1 , figure 2 As shown, the present invention includes a first turnover box conveyor 1, a second turnover box conveyor 6, a two-dimensional platform 9, a support platform 31, a flattening mechanism 13, an upper box return box conversion mechanism 21 and a leaking pipe detection mechanism 14, The end of the first turnover box conveyor 1 is provided with a first box pushing cylinder 2 for pushing the turnover box 33 to the second turnover box conveyor 6, and above the end of the first turnover box conveyor 1 is provided with a box for pushing the turnover box 33 The box cover manipulator 3 that takes off the box cover, the second turnover box conveyor 6 end is provided with the second box pushing cylinder 7 that is used to push the turnover box 33 to the upper box return box conversion mechanism 21, and the upper box return box The conversion mechanism 21 is provided with a third box pushing cylinder 20 for pushing the turnover box 33 with the base pipe to th...

Embodiment 2

[0053] On the basis of the above examples, if figure 1 , figure 2 As shown, the upper box return conversion mechanism 21 is a double-layer structure with a lifting function.

[0054] The upper box returning conversion mechanism 21 is provided with a second box returning cylinder 19 for pushing empty turnover boxes 33 to the second turnover box conveyor 6 .

[0055] The top of the two-dimensional platform 9 is provided with a first box return cylinder 18 for pushing empty turnover boxes 33 to the upper box return conversion mechanism 21 .

[0056] The second turnover box conveyor 6 is provided with a third return box cylinder 5 and is adjacent to the first box push cylinder 2, and the third box return cylinder 5 is provided with an empty box limit cylinder 27 near the first box push cylinder 2 .

[0057] The second turnover box conveyor 6 is provided with a box returning platform 28 for over-empty turnover boxes 33 .

[0058] The box returning platform 28 is provided with ...

Embodiment 3

[0061] On the basis of the above examples, if Figure 1-2 As shown, the second turnover box conveyor 6 is provided with a combination mold conveyor 23 below, the combination mold conveyor 23 is provided with a fifth pushing mold cylinder 30, and the fifth pushing mold cylinder 30 is oppositely provided with a combination mold conveyor belt 24 , the combined mold conveyor belt 24 ends are provided with the first pushing mold cylinder 10, the combined mold conveyor 23 one end is provided with the dragging mold cylinder 17 and is close to the support platform 31, and the dragging mold cylinder 17 below is provided with the combination mold lifting upper mold mechanism 16.

[0062]Concrete, the mold dragging cylinder 17 is set above the upper mold mechanism 16 of the combination mold lifting, the combination mold 32 is lifted to the plane of the combination mold conveyor 23 through the combination mold lifting upper mold mechanism 16, and the mold pulling cylinder 17 drags the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com