A cable for corrosive soil and its matching installation process

A corrosive and cable technology, which is applied in the field of corrosive soil cables and its supporting installation technology, can solve the problems of cable service life, safety hazards, leakage, etc., to increase safety, reduce the possibility of leakage, and facilitate The effect of installing a fixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

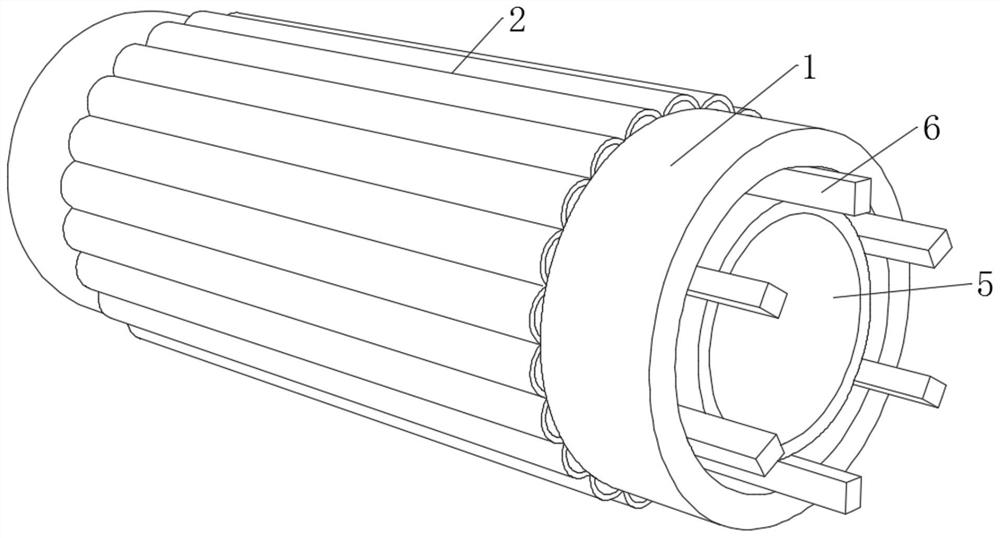

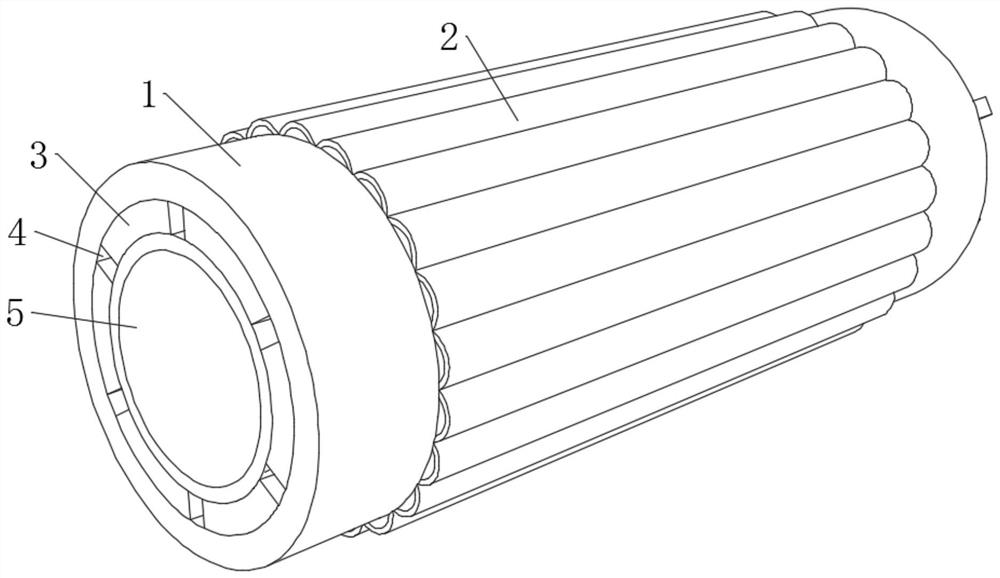

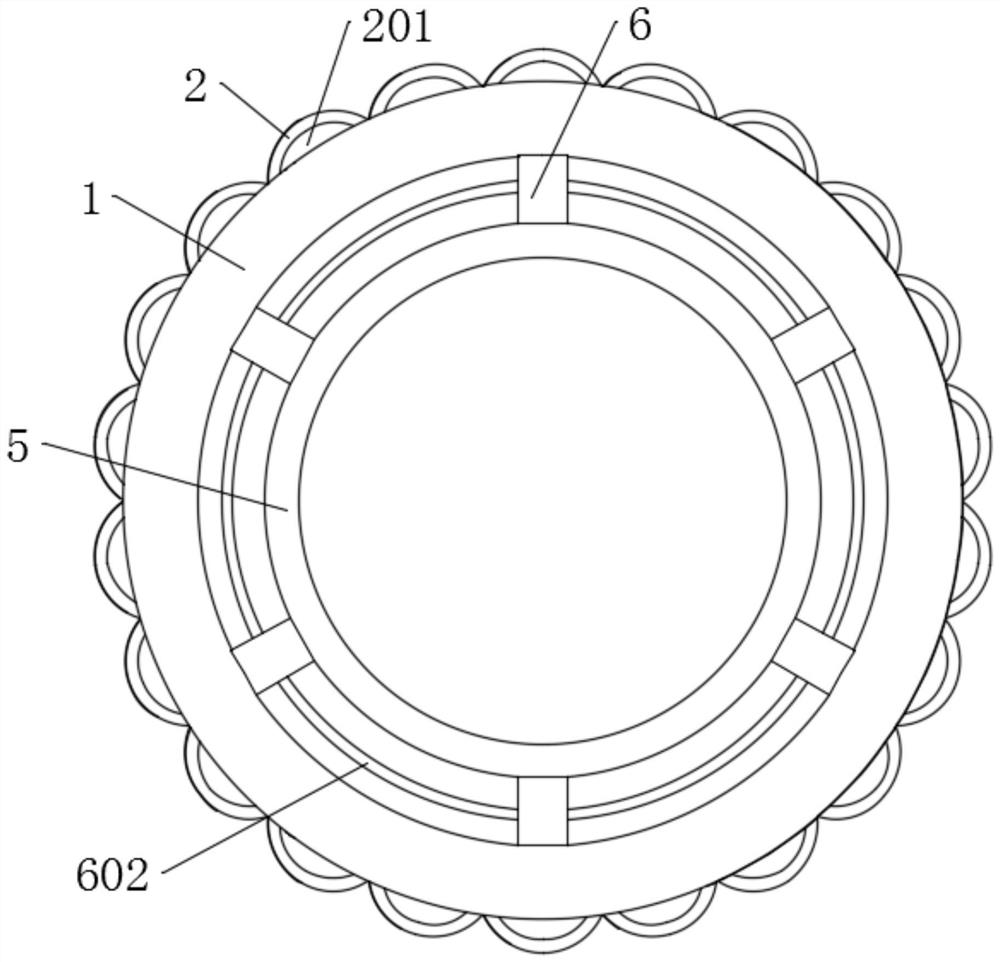

[0050] A cable for corrosive soil and its matching installation process, including an anti-corrosion pipeline 1, the outer end of the anti-corrosion pipeline 1 is fixedly connected with a plurality of auxiliary support blocks 2, and the plurality of auxiliary support blocks 2 are evenly distributed on the anti-corrosion pipeline 1 The outer end of the auxiliary support block 2 is drilled with an arc-shaped through hole 201 near the end of the anti-corrosion pipeline 1, so that the auxiliary support block 2 has a stronger buffer performance. When the anti-corrosion pipeline 1 is buried in the soil, it can reduce The stress effect of the upper soil on the anti-corrosion pipeline 1 reduces the possibility of damage to the anti-corrosion pipeline 1. The material of the auxiliary support block 2 is polyethylene plastic, which has corrosion resistance and electrical insulation, and the anti-corrosion pipeline 1 After being buried in the corrosive soil, the auxiliary support block 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com