Printing machine roller

A technology for printing machines and cleaning rollers, which is applied to printing machines, rotary printing machines, printing, etc., and can solve the problems of not being able to clean the edges of the machine rollers and the ink in the micropores, and achieve the effect of being easy to disassemble and wash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

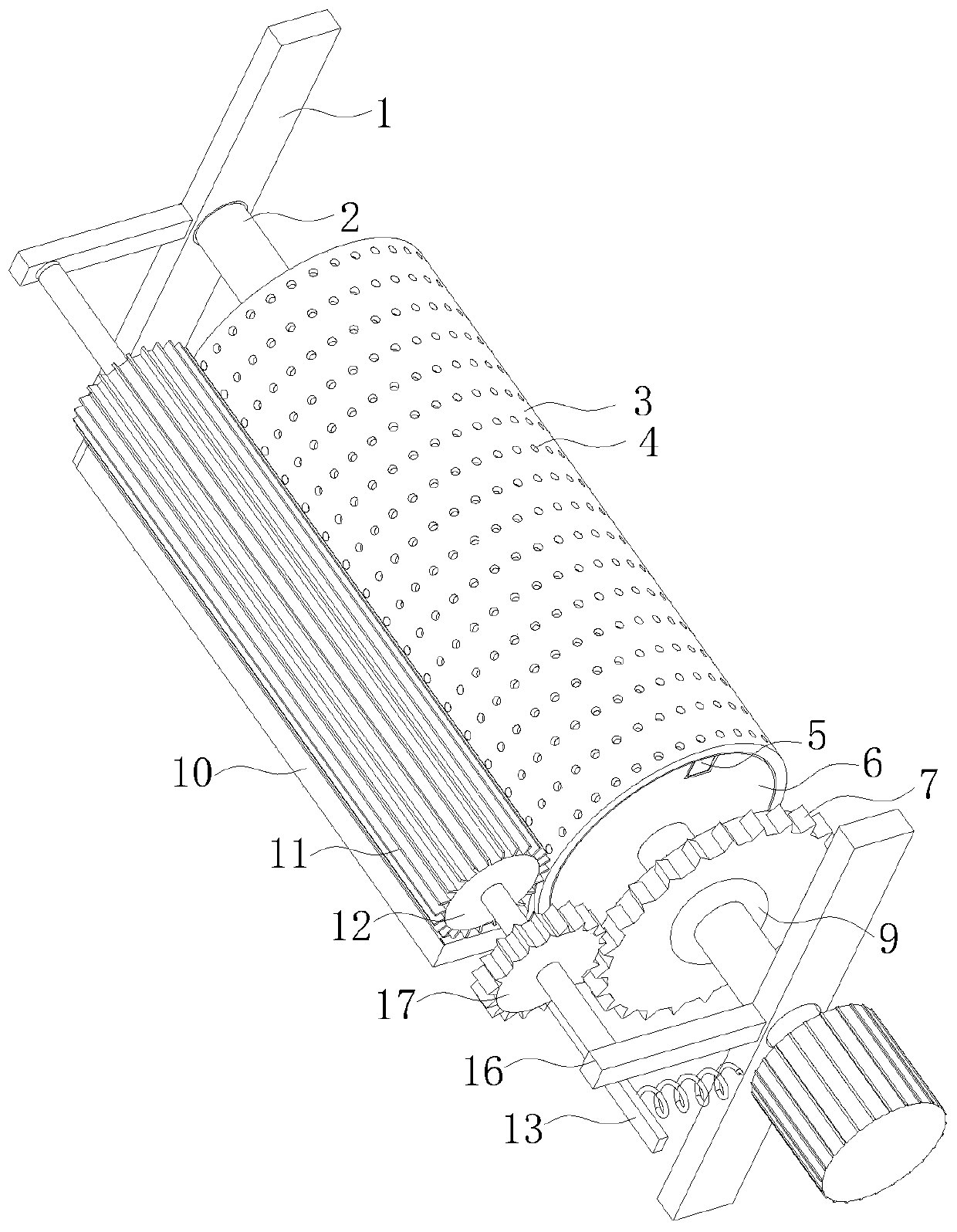

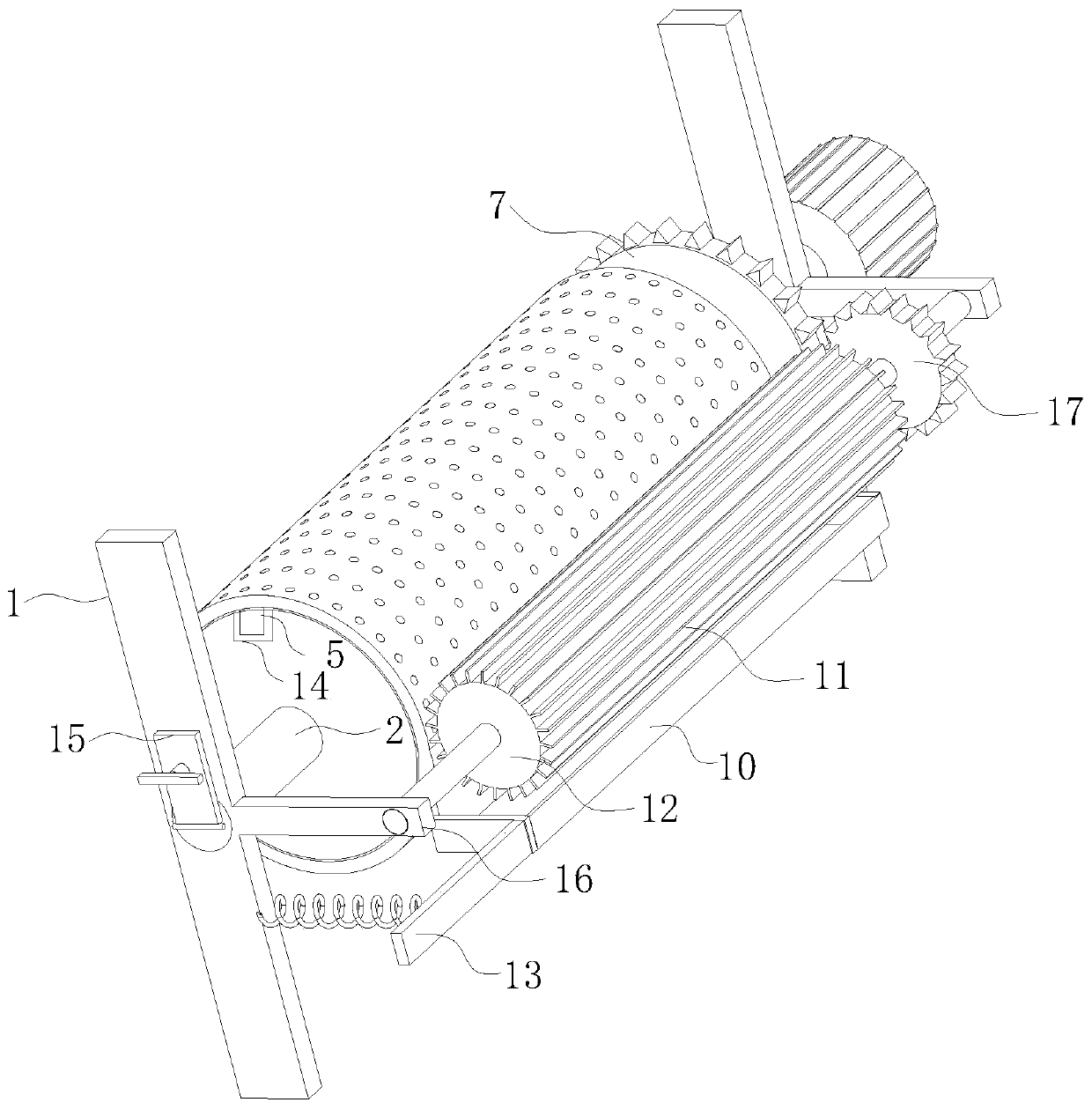

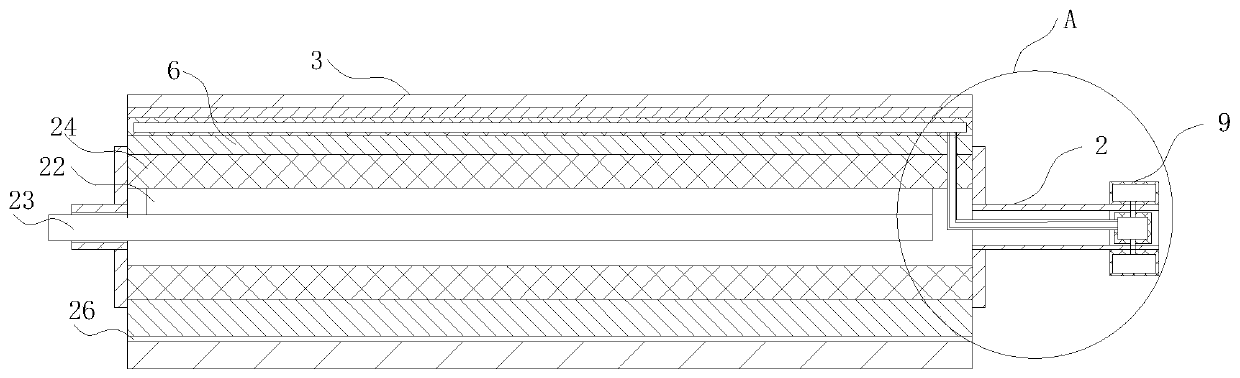

[0029] As an embodiment of the present invention, the rotating shafts at both ends of the cleaning roller 12 are movably connected to the horizontal mounting plate 16; one end of the horizontal mounting plate 16 is fixedly connected to the vertical support frame 1; the cleaning roller 12 An acceleration gear 17 is fixed on the rotating shaft close to the driving motor; the acceleration gear 17 is engaged with the active round gear 7 fixed on the rotating tube 2 for transmission; when working, the driving motor drives the rotating tube 2 to rotate, thereby driving the rotating tube 2 to rotate. The driving circular gear 7 on the tube 2 rotates, and the driving circular gear 7 drives the cleaning roller 12 to rotate through the engagement transmission with the acceleration gear 17, and since the rotating speed of the cleaning roller 12 is greater than the rotating speed of the outer casing 3, it is located at the edge of the cleaning roller 12 The rubber soft plate 11 can quickly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com