Four-way walking trolley

A traveling trolley and traveling wheel technology, applied in transportation, packaging, storage devices, etc., can solve the problems of low shelf access efficiency, insufficient load capacity, poor operation capacity, etc., to improve stability, flexibility, and load capacity. , the effect of saving power plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

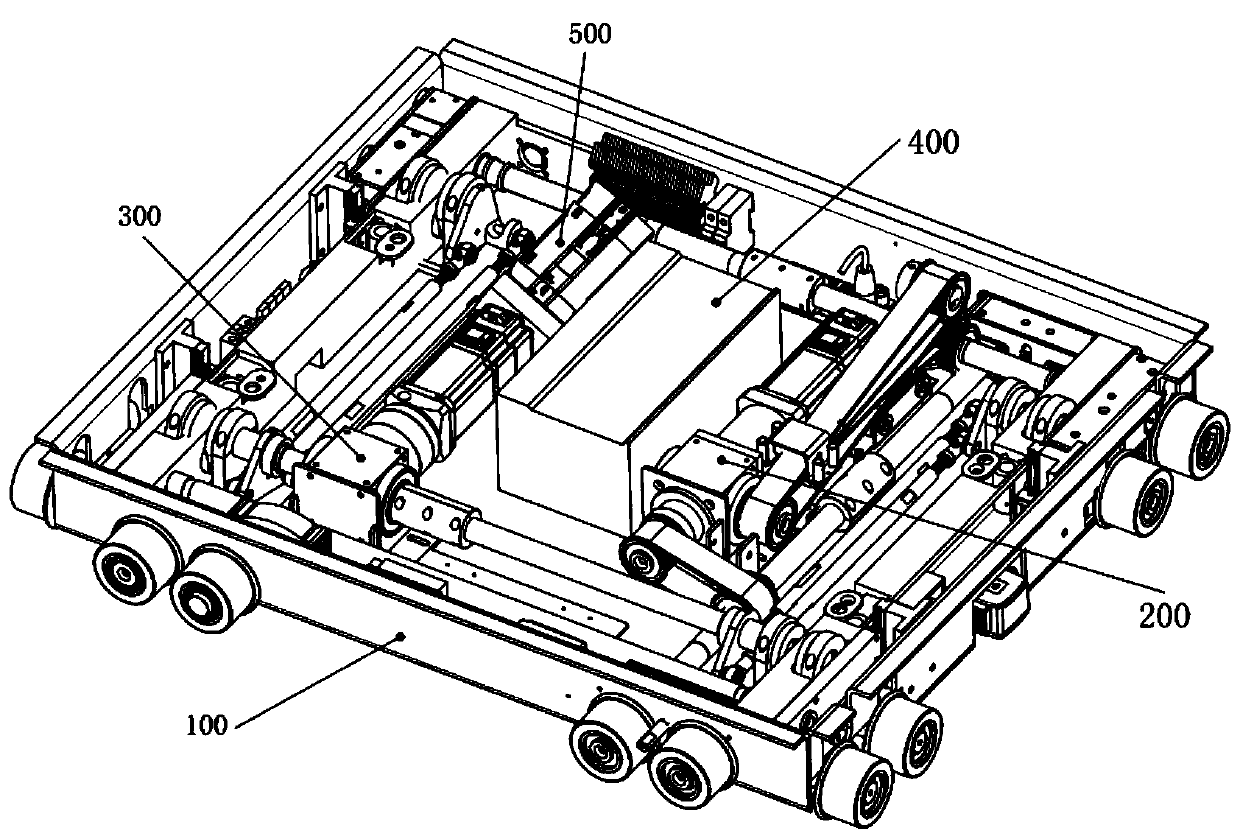

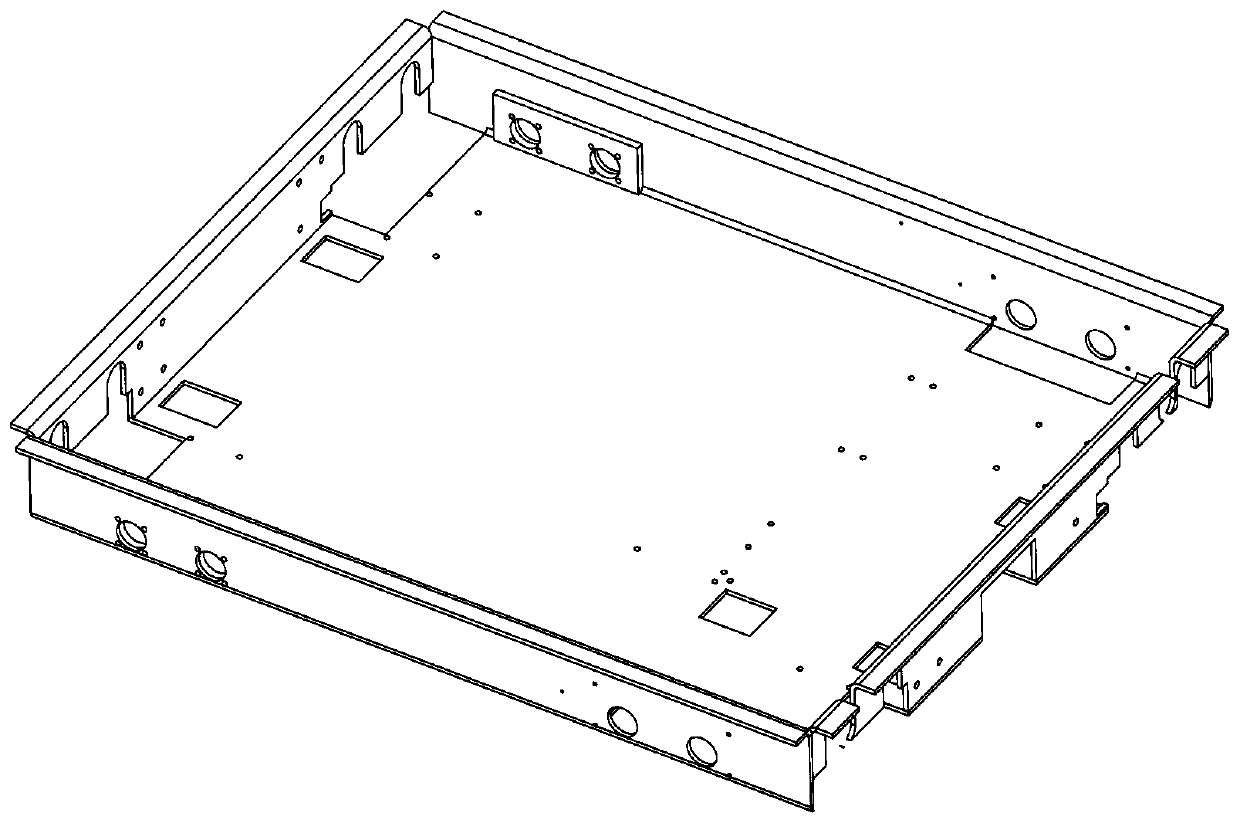

[0044] see figure 1 with figure 2As shown, this embodiment provides a four-way walking trolley, which can travel vertically and horizontally in four directions, and the existing four-way walking trolley is used to replace the existing combined system of child and mother vehicles, which improves the space utilization rate , It also improves the access efficiency of the shelf; it includes the supporting frame 100, the walking drive module 200, the reversing and jacking module 300, the battery pack 400, and the six modules that have been omitted from the shell. Wherein, the walking drive module 200 , the reversing and lifting module 300 , the battery pack 400 and the battery pack 400 on the support frame 100 are all mounted on the support frame 100 . The traveling drive module 200 and the reversing and jacking module 300 in the four-way traveling trolley all adopt a mechanical structure, which solves the leakage problem of the hydraulic device used in the prior art and improves...

Embodiment 2

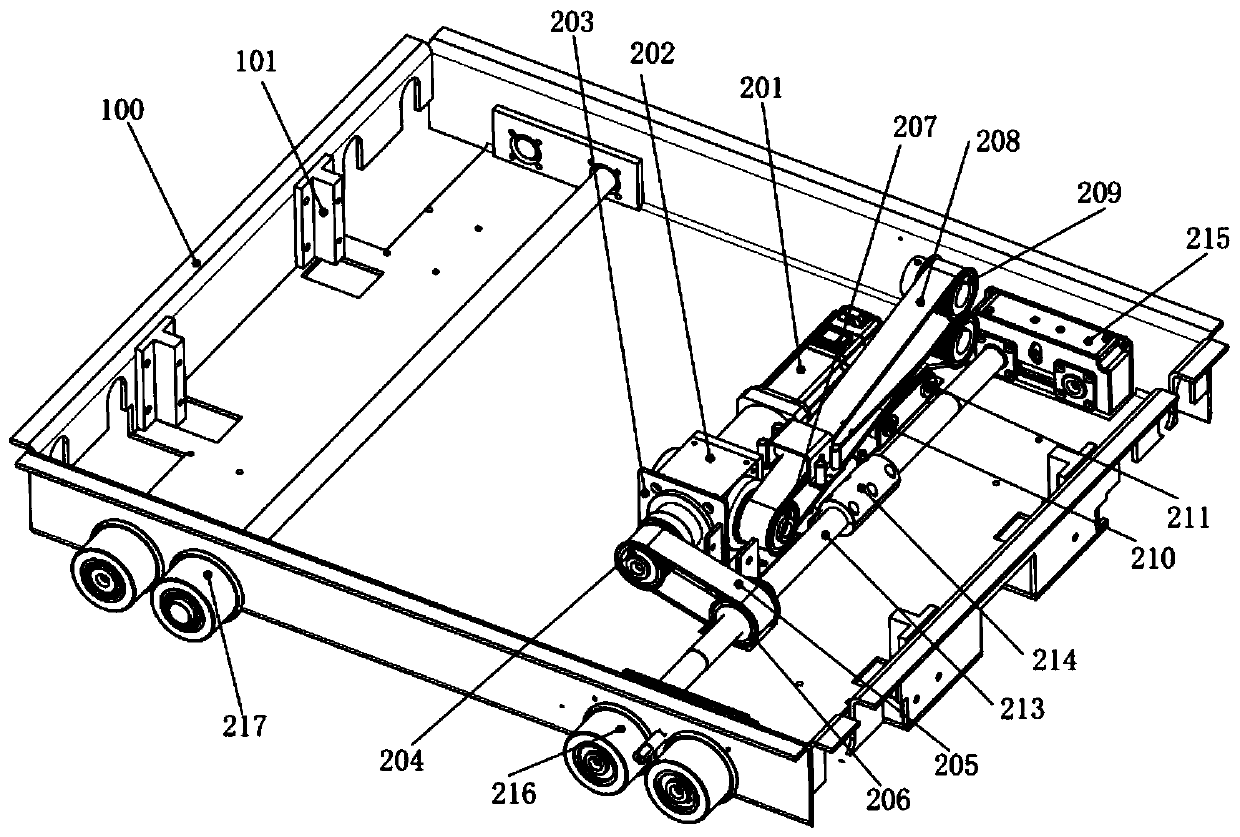

[0050] Based on the four-way walking trolley described in the above-mentioned embodiment 1, this embodiment provides a tensioner wheel structure for the four-way walking trolley. During the process, only one set of tensioner structure is used, which saves space and reduces cost.

[0051] The tensioner structure provided in this embodiment is mainly composed of five synchronous wheels in total, the second synchronous driving wheel 207, the second synchronous passive wheel 209, the first tensioning wheel 210, the second tensioning wheel 211, and the third tensioning wheel 212. Composition, the second synchronous driving wheel 207 is fixed on the drive motor 201, the second synchronous driven wheel 209 is fixed on the transverse drive shaft 213, and the second synchronous driving wheel 207 and the second synchronous driven wheel 209 are connected with the second synchronous belt 208 , the first tensioner 210 , the second tensioner 211 are at a specific position below the second s...

Embodiment 3

[0056] Based on the four-way traveling trolley of the above-mentioned embodiment 1, the present embodiment provides a horizontal traveling wheel assembly and a longitudinal traveling wheel assembly for the four-directional traveling trolley, the transverse traveling wheel assembly and the longitudinal traveling wheel assembly adopt four wheels on one side , and the use of strengthened support frame and jacking frame improves the load capacity.

[0057] see figure 1 with image 3 As shown, the lateral travel wheel assembly includes a first driving wheel 216 and a first driven wheel 217 distributed on the front and rear sides of the support frame 100, and the first driving wheel 216 is laterally driven by the first power distributor 215 The shaft 213 is drivingly connected to the first synchronous driven wheel 206 , and the transverse drive shaft 213 is composed of two parts connected by a transverse coupling 214 .

[0058] In this embodiment, the first driving wheel 216 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com