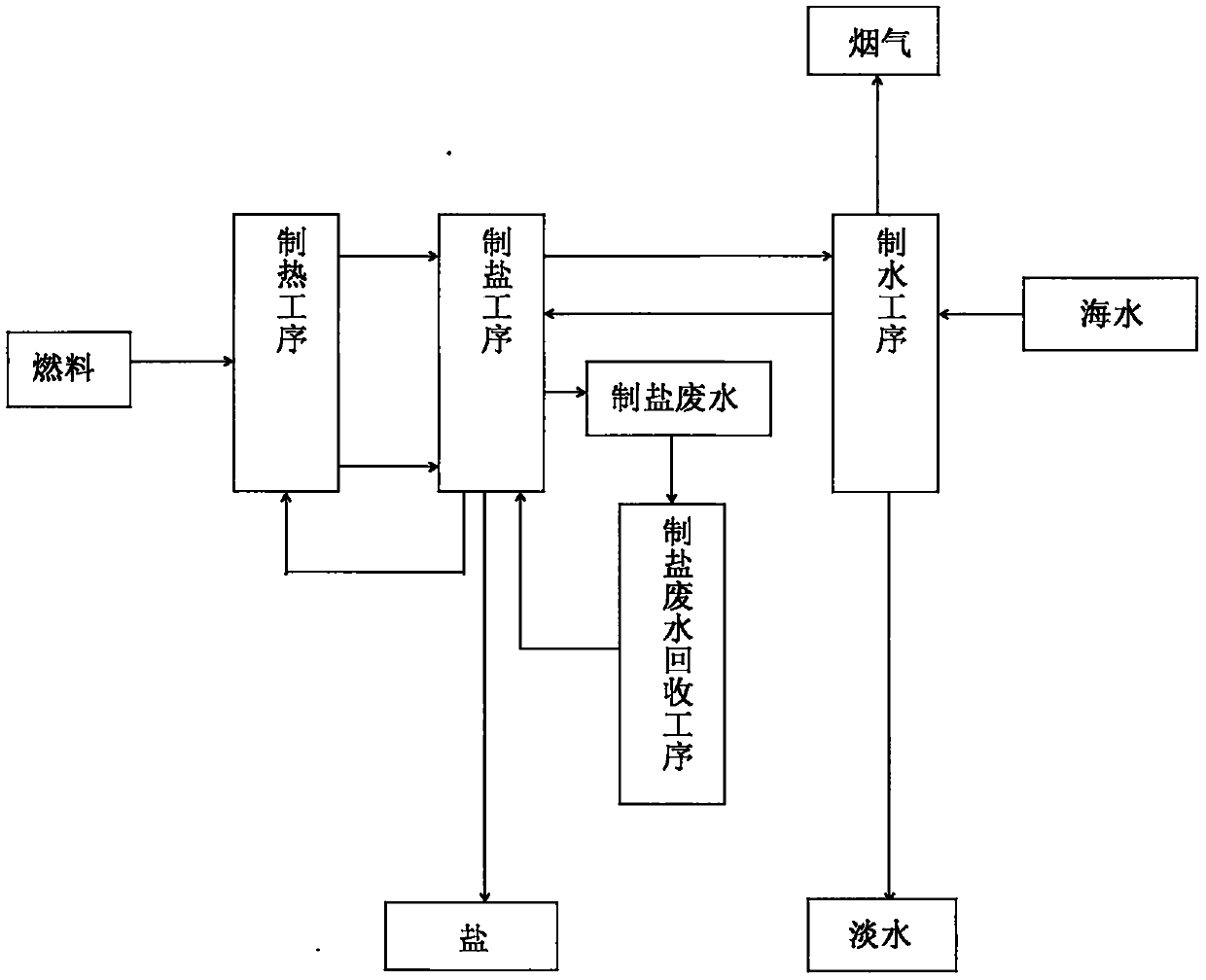

Hot-method seawater desalination technology for solid-liquid separation

A solid-liquid separation and process technology, which is applied in the field of thermal seawater desalination process, can solve problems such as imperfect process, achieve the effects of saving equipment manufacturing costs and operating costs, increasing fresh water production, and improving fresh water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

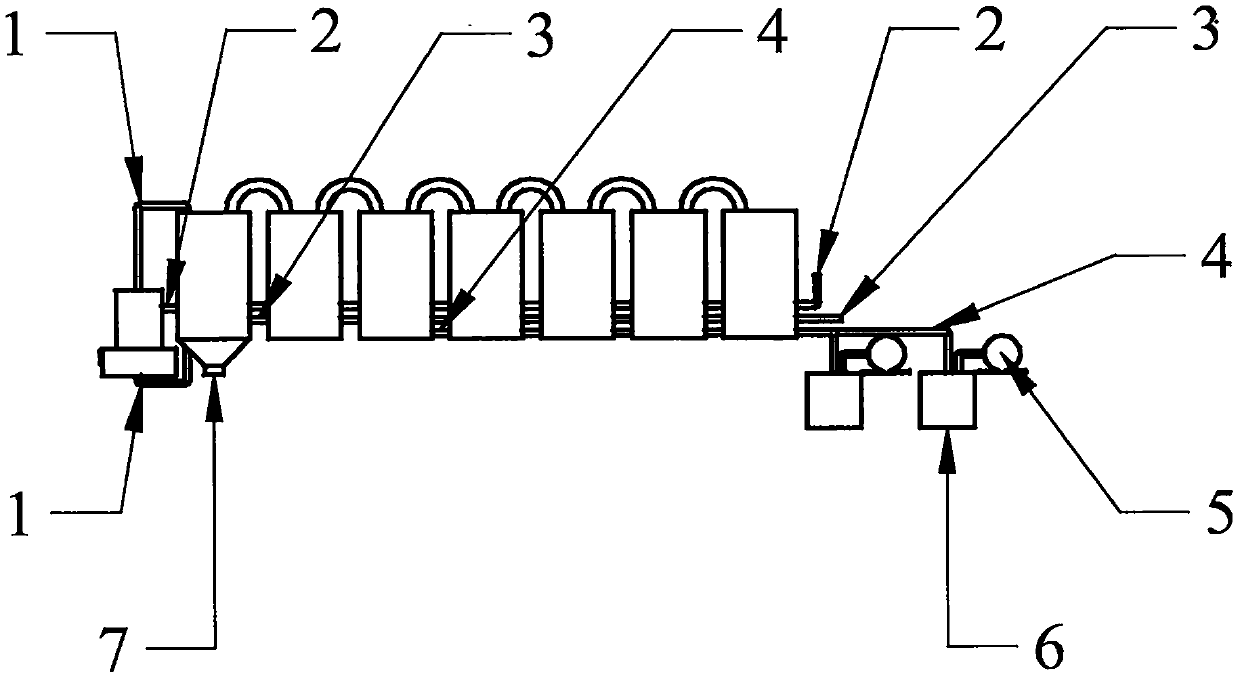

[0013] The embodiment is a set of seawater desalination device which uses oil and gas as fuel and has seven stages of seawater evaporation tanks. Such as figure 2 shown. The boiler in the heating process adopts the fuel-fired gas-fired boiler described in Chinese invention patent 201510379482.0. The salt making process includes 2-stage seawater evaporation tanks of the first stage and the second stage. The water production process includes 5-stage seawater evaporation tanks from the third stage to the seventh stage. The recovery process of salt-making wastewater is that the bottom of the condenser of the second-stage seawater evaporation tank is connected to the second-stage seawater evaporation tank. Salt wastewater recovery channels are simplified. The steam condensed water circulation loop 1 is from the steam outlet of the boiler, and returns to the water inlet of the boiler through the condenser of the first-stage seawater evaporation tank. The inlet of the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com