Middle pressure foot structure of sewing machine

A sewing machine and medium-pressure technology, which is applied in the direction of sewing machine components, cloth pressing mechanism, sewing equipment, etc., can solve problems such as complex structure, and achieve the effect of compact structure and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

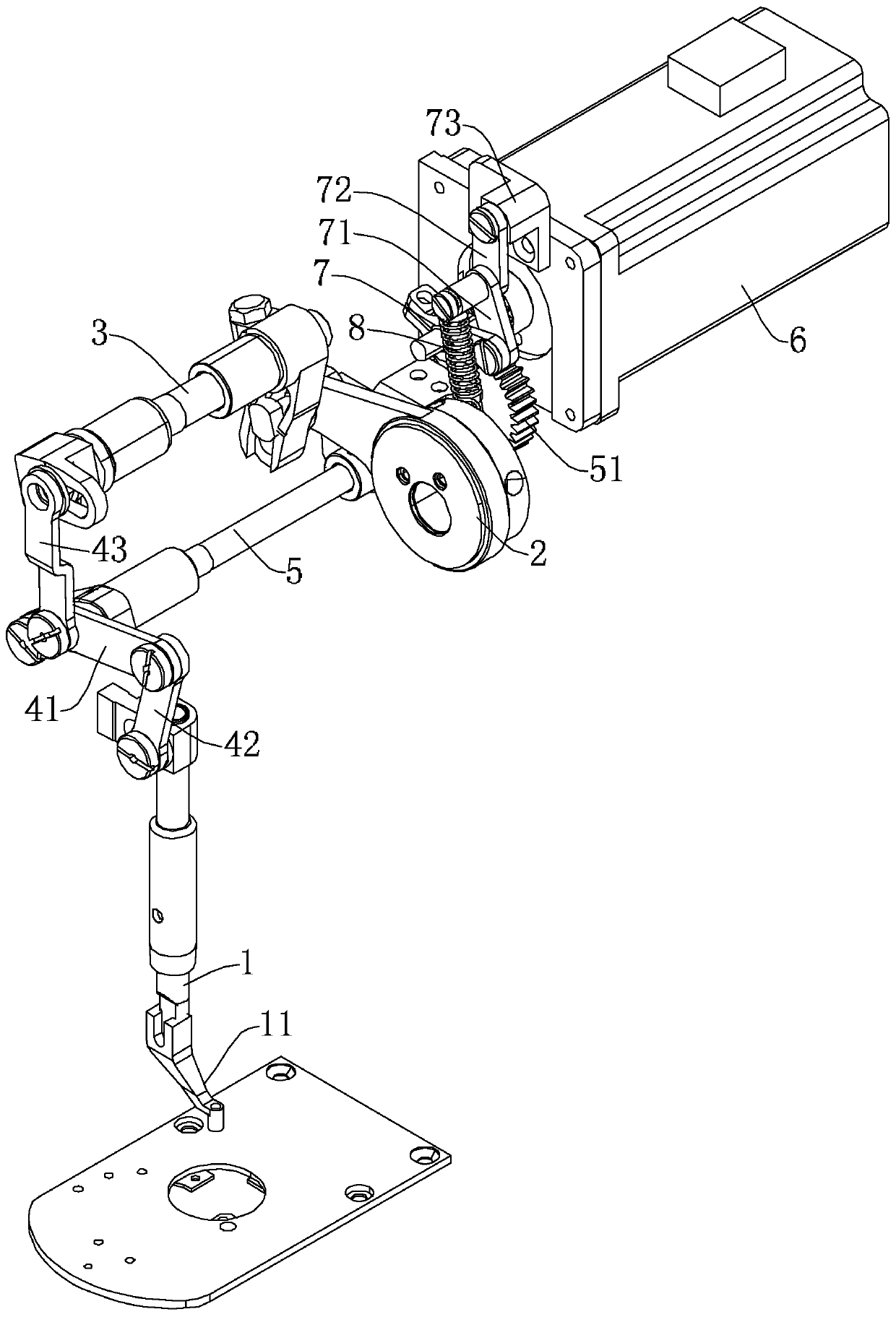

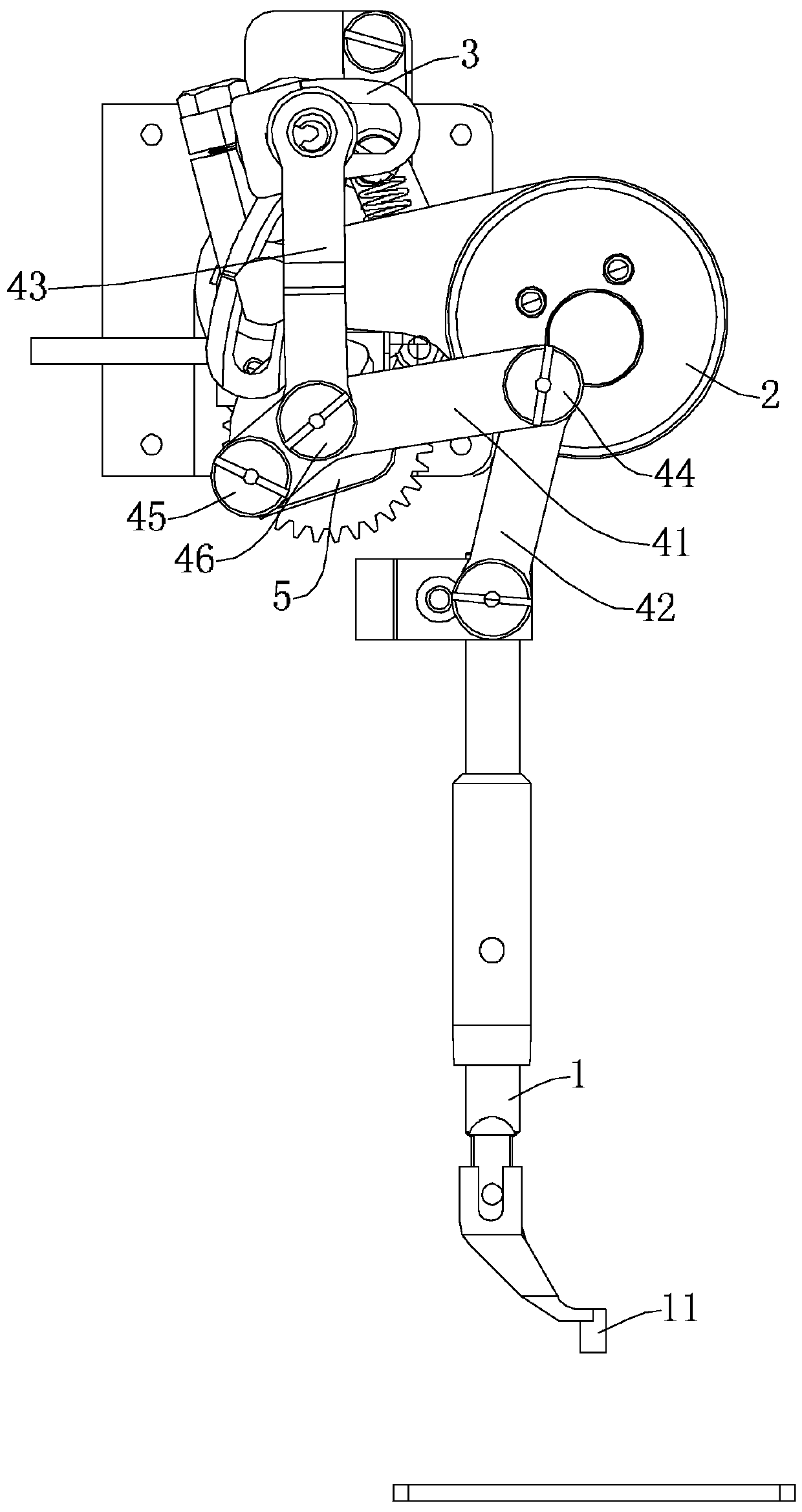

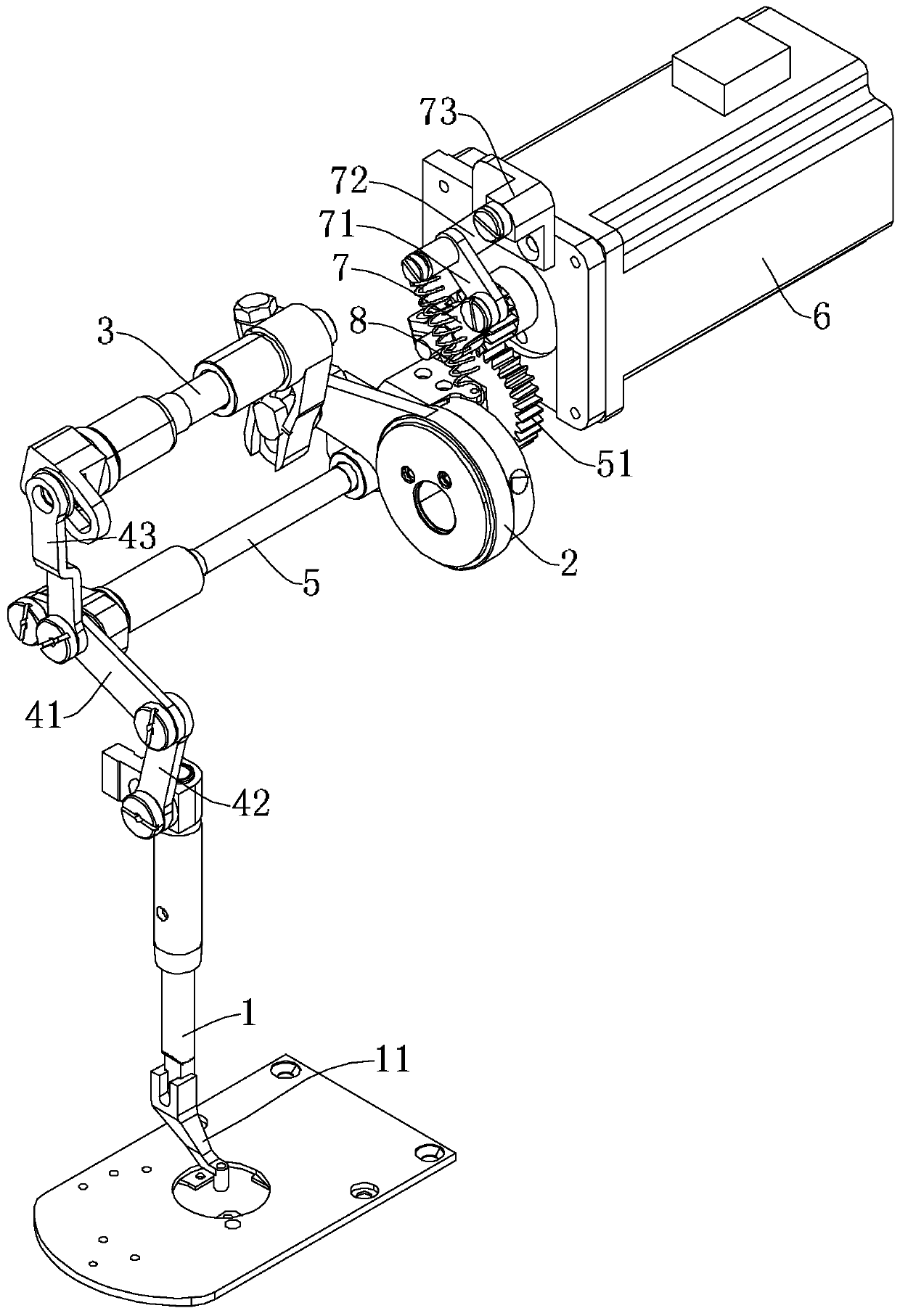

[0020] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

[0021] The reference signs are: presser foot rod 1, intermediate presser foot 11, cam crank 2, eccentric cam 2a, sleeve part 2b, third crank part 2c, drive crank shaft 3, first straight rod part 3a, first Crank portion 3b, second crank portion 3c, first connecting rod 41, second connecting rod 42, third connecting rod 43, first rotating shaft 44, second rotating shaft 45, third rotating shaft 46, lifting control crank shaft 5, the first rotating shaft Two straight rod parts 5a, the fourth crank part 5b, transmission gear 51, induction plate 52, sensor 53, motor 6, power output shaft 61, power gear 62, reset crank 7, tight ring part 7a, the fifth crank part 7b, The fourth connecting rod 71 , the fifth connecting rod 72 , the first fixing seat 73 , t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap