Safety protection device for preventing pipeline leakage

A technology of safety protection device and pipeline, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problem that the position of the main switch of the pipeline is too concealed, the position of the main switch of the pipeline is difficult to change, and the gas hose pipeline leaks, etc. problems, to achieve the effect of reducing the risk of pipeline leakage, easy operation and popularization, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

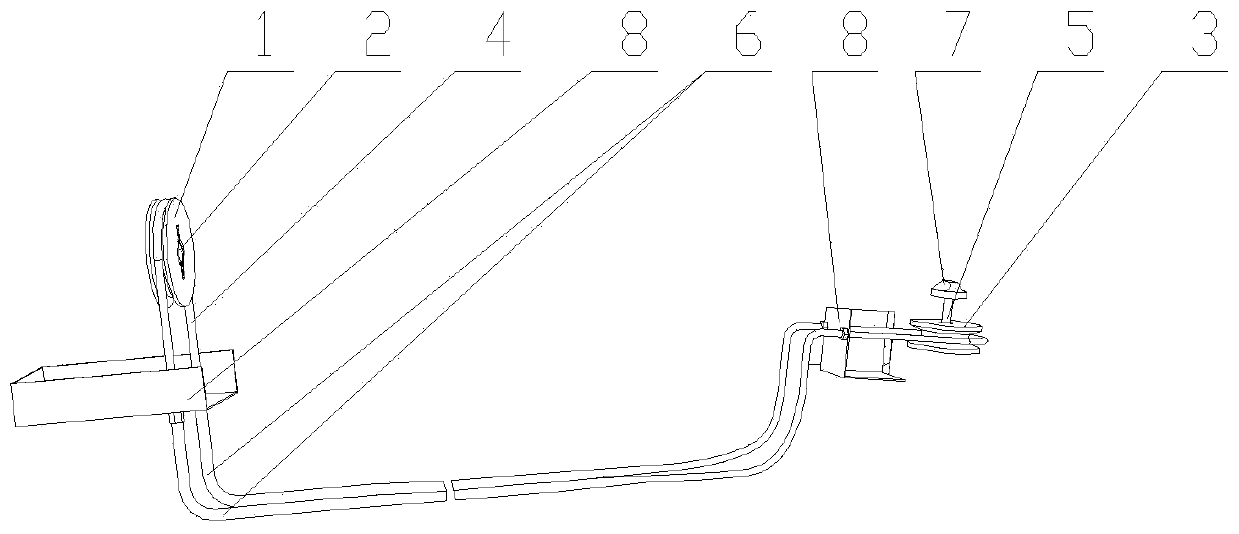

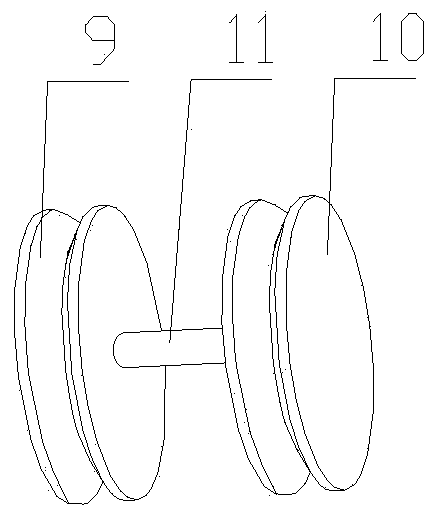

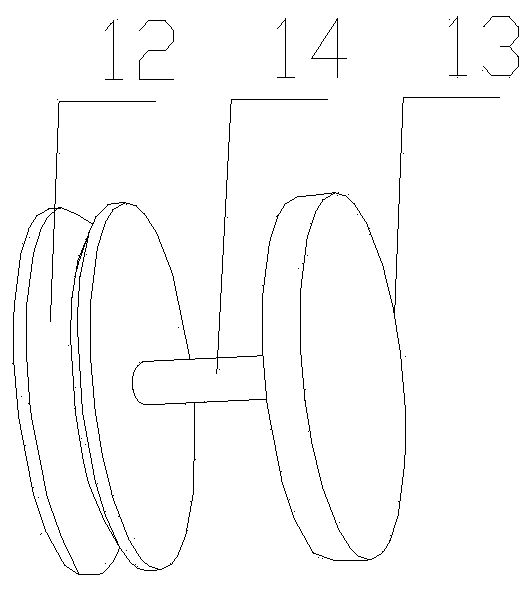

[0020] The main structure of the safety protection device for preventing pipeline leakage involved in this embodiment includes: a first pulley 1, a through hole 2, a second pulley 3, a steel cable 4, a central shaft 5, a steel cable casing 6, a switch knob 7, Fix the shell 8; the diameter of the first pulley 1 is 15-40mm, and the thickness is 5-15mm. A groove around the circumference of the first pulley 1 is arranged on the outer peripheral surface, and the width of the groove is 3-10mm. The size of the first pulley 1 matches the steel cable 4 and can accommodate the steel cable 4. The center of the first pulley 1 is provided with a through hole 2. The shape of the through hole 2 matches the main switch of the pipeline. The through hole 2 is set on the main switch of the pipeline and can Drive the main switch of the pipeline to rotate synchronously, the material of the first pulley 1 is metal or plastic; the size and material of the second pulley 3 are the same as that of the f...

Embodiment 2

[0027] The main structure of the safety protection device for preventing pipeline leakage involved in this embodiment is the same as that of Embodiment 1, the steel cable 4 adopts a brake line, the steel cable sleeve 6 is a bendable metal tube, and the first pulley The through hole 2 of 1 is in-line or butterfly shape, and the corner radius of the cable casing 6 at the corner of the cable 4 line is 120 mm or more.

[0028] Further, the brake line is made of high carbon steel with a specification of 1×12.

[0029] Further, the cable casing 6 is a brake line casing.

[0030] Further, the preload of the cable is 4 lbs.

Embodiment 3

[0032] The main structure of the safety protection device for preventing pipeline leakage involved in this embodiment is the same as that of Embodiment 1. The device is applied to indoor gas pipelines and installed on the main switch of the gas pipeline and the ignition stove to prevent gas leakage. Knob 7 is installed on the ignition stove top or the stove cabinet wall, etc., where it is easy to touch. The through hole 2 of the first pulley 1 is set on the gas pipeline master switch, and the fixed shell 8 is fixed on the cabinet wall, wall or pipeline. The steel cable sleeve 6 is fixed on the fixed shell 8, and the steel cable 4 covered with the steel cable sleeve 6 is wrapped around the first pulley 1 and the second pulley 3; when it is necessary to open the main switch of the pipeline, turn the switch knob 7 counterclockwise , the switch knob 7 drives the second pulley 3 to rotate through the central shaft 5, the second pulley 3 drives the steel cable 4 to rotate synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com