Shear nail anti-pulling test loading device used in cooperation with pressure testing machine

A pressure test and loading device technology, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve problems that cannot be used to study shear nail cone failure, yield failure, etc. And the measurement process is convenient and fast, avoiding collision and jamming, and the effect of stiffness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

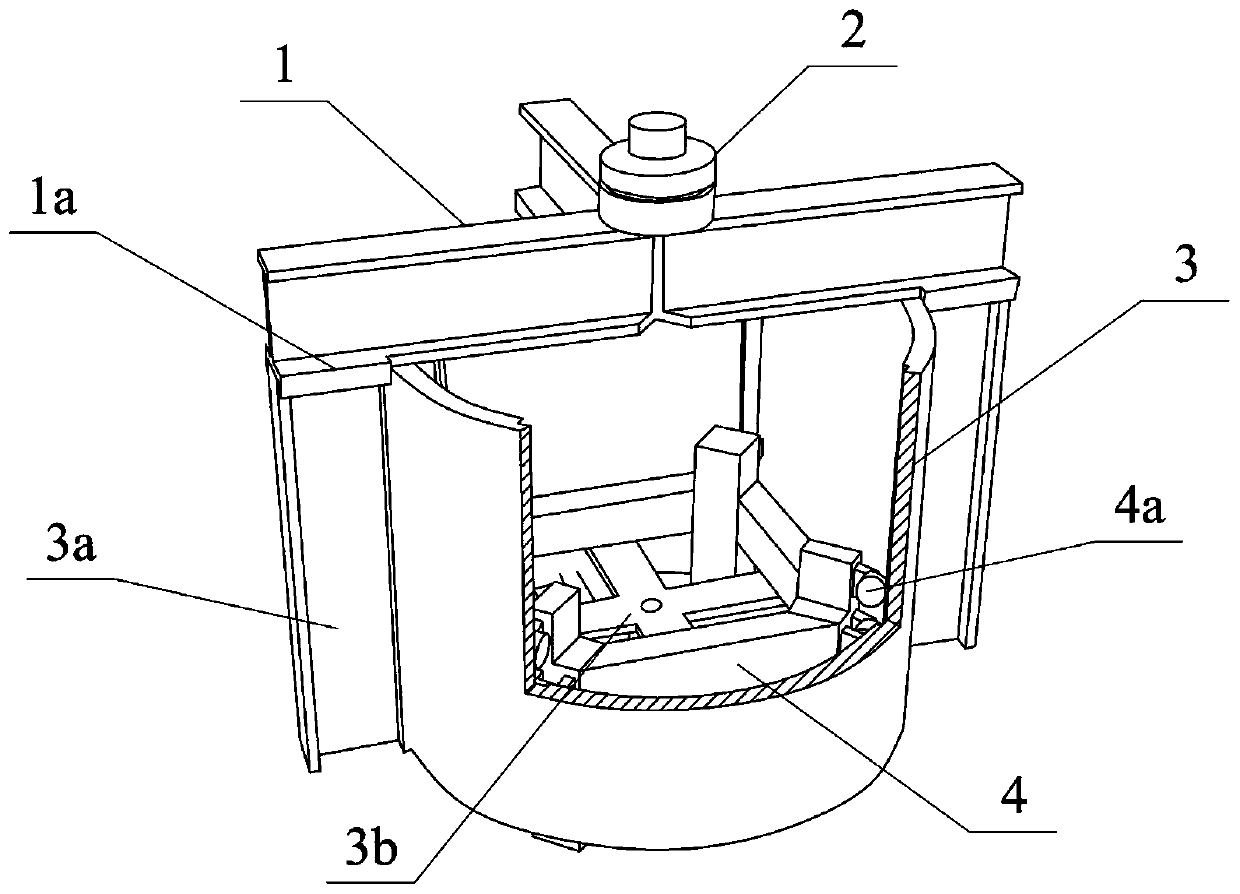

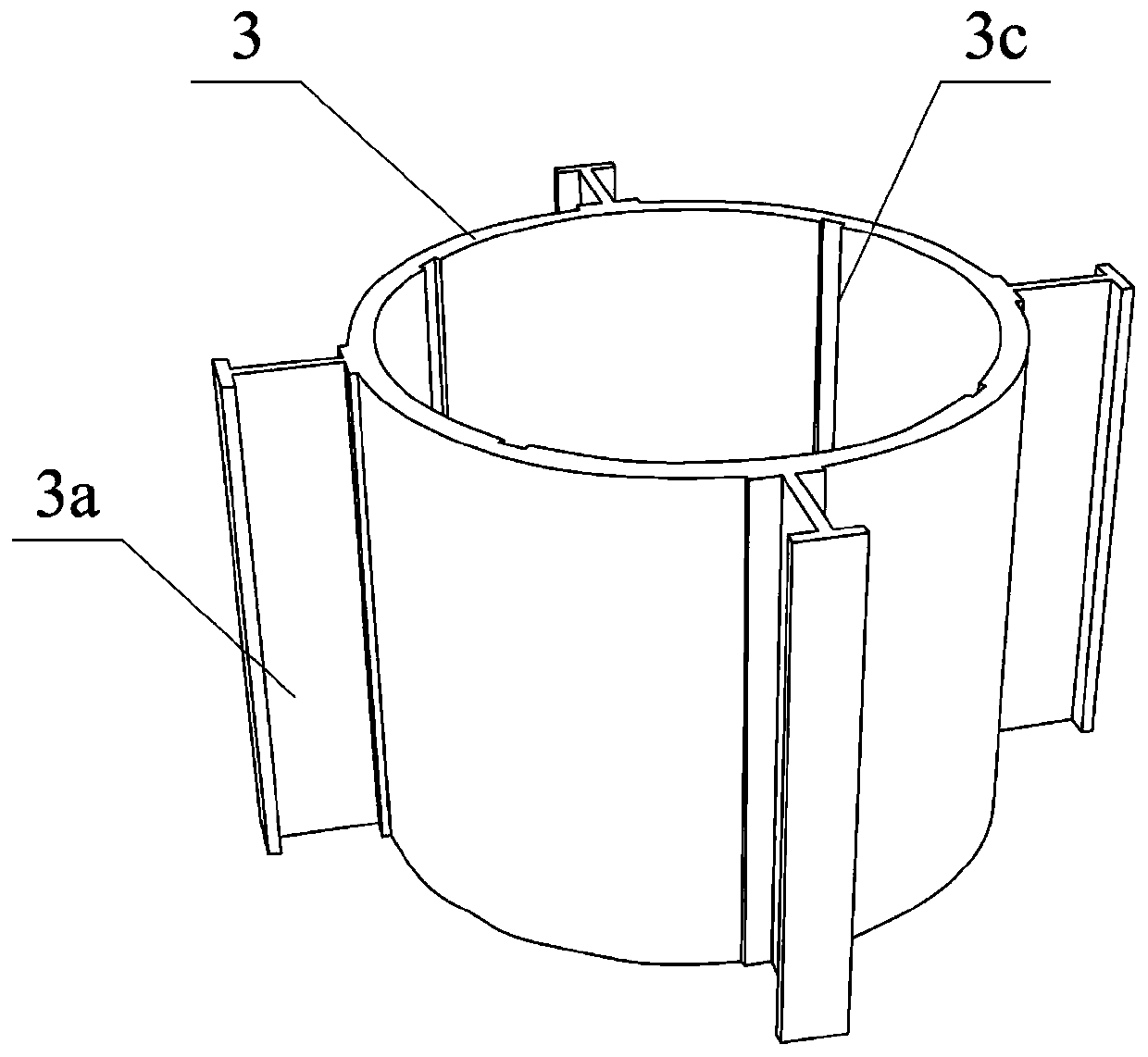

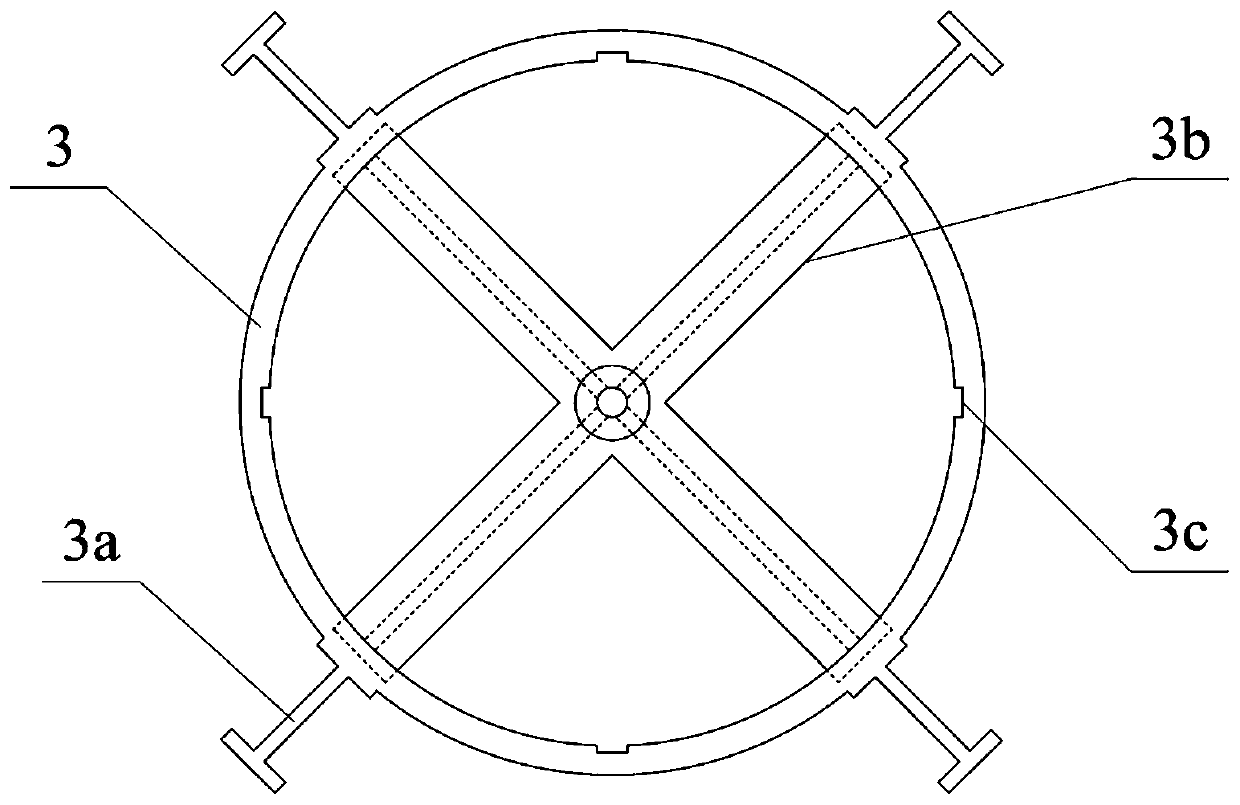

[0034] Such as Figure 1-9 As shown, a shear nail pull-out test loading device used in conjunction with a pressure testing machine includes a device body 3 which is hollow inside and a shelf 4 arranged inside it; the shelf 4 includes n legs, n≥3 , the upper parts of adjacent legs are connected by pillars to form an n-sided structure; the outer sides of the 4 legs of the storage rack are in sliding contact with the inner wall of the device body 3; the lower ends of the 4 legs of the storage rack protrude from the hollow bottom of the device body 3; On the frame 4, one end of the shear nail is buried in the concrete 6, and the other end protrudes from the bottom surface of the device body 3; one end of the shear nail protruding from the bottom surface of the device body 3 is provided with an external thread and a high-strength bolt 5; the loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com