An orthopedic arthroscopic wire passing device

An arthroscopic and orthopedic technology, applied in applications, surgical instruments, etc., can solve the problems of easy falling off, inconvenient use of surgical tools, and various surgical tools, so as to avoid loss, simple and practical disinfection operation, and reduce the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

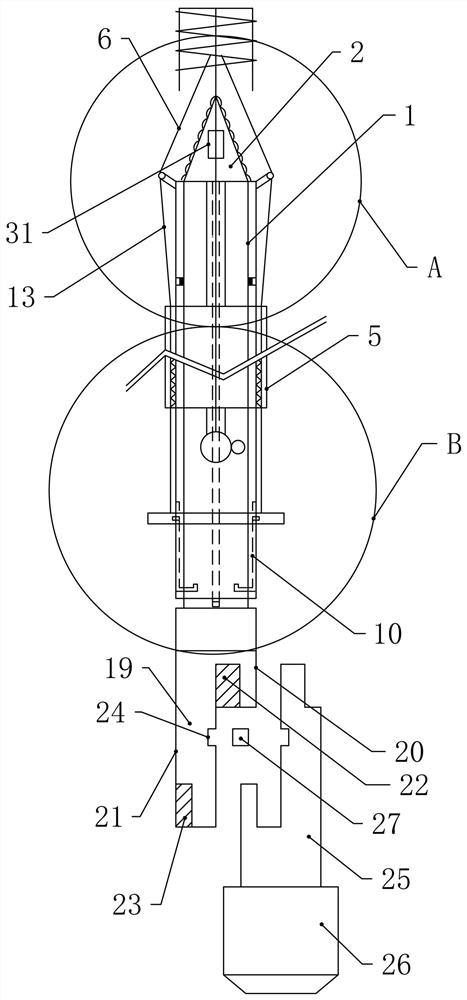

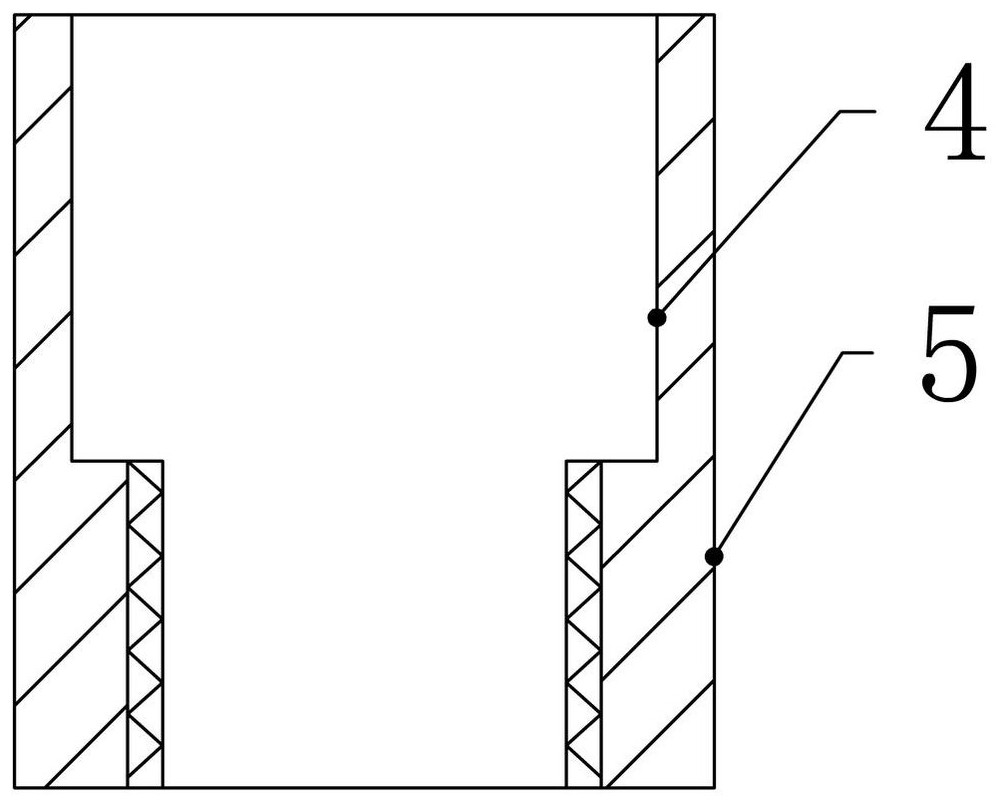

[0065] Embodiment 2, in particular, a ring-shaped slider one 15 is fixed to the inner side wall of the sleeve 4, and the slider one 15 can be rotated in the slide rail. To ensure that the cylinder is rotated in normal rotation, the sleeve is not rotated.

Embodiment 3

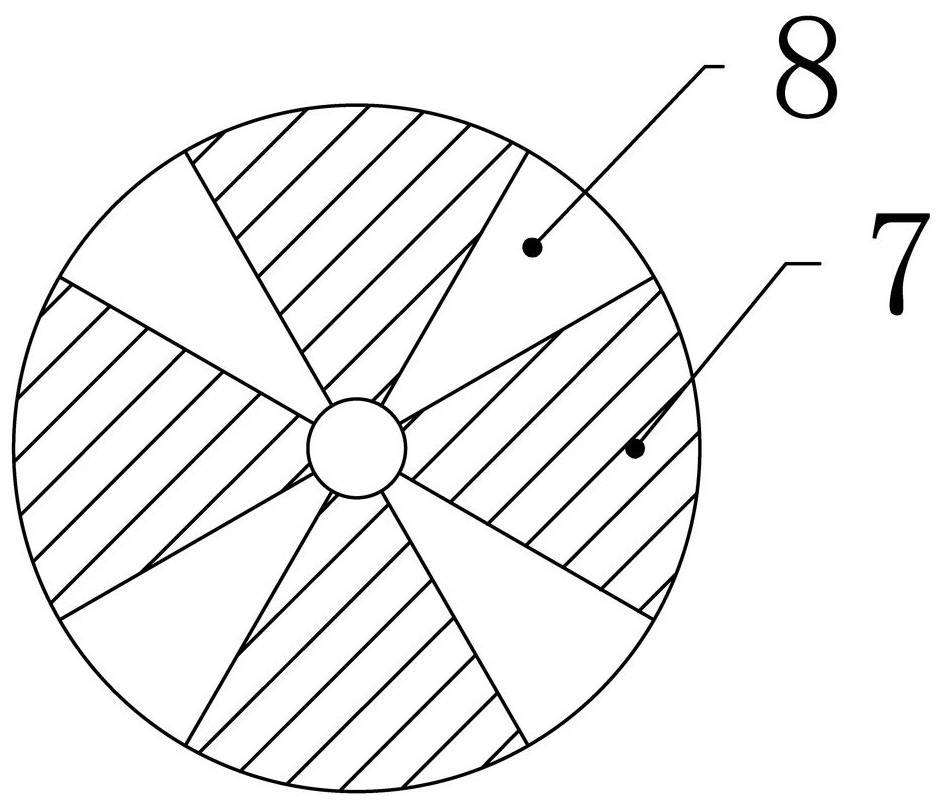

[0066] Example III, in particular, the rotation of the drill plate 7 requires a rotating portion, the rotation portion mounted a bracket 16 that matches the number of drills 7 in the outer wall of the sleeve 4, that is, there are 4, the bracket 16 is An angled tilt setting is attached to the end of the bracket 16, and a shaft piece 7 is fixed to the shaft portion 17, and the shaft shaft one 17 is connected to the shaft 9, and the coaxial 17 is provided with a coaxial spring 18.

[0067] When using, when the drill piece 7 is placed outside the spiral turnt head 2, a spacing 8 is left between each of the two drill pieces 7, and the tip of the drill 7 is circular. The circle is relatively small, does not affect the drilling, and the coil spring 18 at this time makes the drill 7 have a pressing force in the direction of the spiral turnt head 2. When the drill piece 7 is pulled, the reel spring 18 begins to be affected. Force status.

Embodiment 4

[0068] Example 4, in particular, the length of the drill table 7 is greater than the length of the spiral turnt head 2 such that the drill 7 can be wrapped in the spiral turnt head 2 (not completely sealed), and the end of the upper end of the sleeve 2 5 The distance between the end to the upper end of the sleeve 4 is greater than the length of the drill piece 7.

[0069] As such, the spiral turnt head 2 is placed in the drill bit 6, and when the drill block 7 is pulled, the drill table 7 starts flipping, and the diamonds 7 after the flipping drill 7 have not been exposed to the sleeve 2 5, and the subsequent drill pieces 7 enters The inner side wall of the sleeve is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com