Cutting device for electronic mainboard production

A technology of cutting device and main board, which is applied to the separation of dispersed particles, the use of liquid separating agent, metal processing, etc. It can solve the problems of high dust concentration in the production workshop, lower cutting precision, easy shaking and displacement, etc., to improve cutting stability, Improve stability and reduce the effect of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

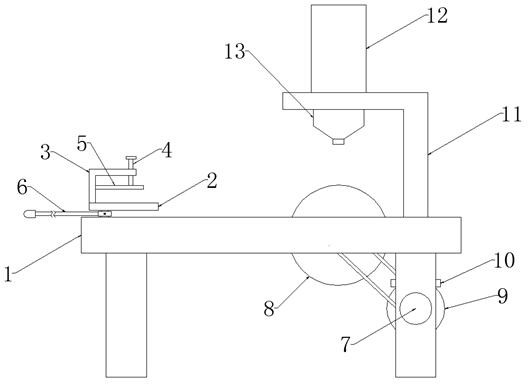

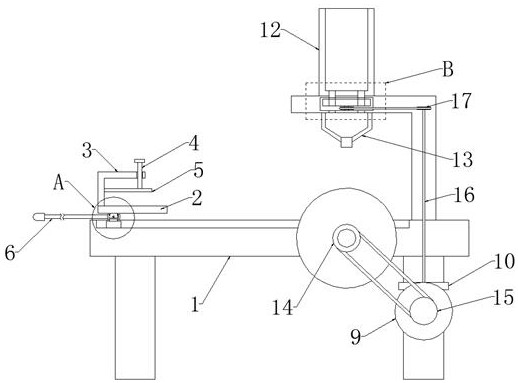

[0025] Embodiment 1: When the device is in use, the electronic main board to be processed is first placed between two clamping plates 2 for clamping, and then the threaded rod 4 is rotated so that the threaded rod 4 pushes the pressing plate 5 to move downward, thereby making The electronic main board to be processed can be limited and fixed in the horizontal and vertical directions to prevent it from shifting during the cutting process.

Embodiment 2

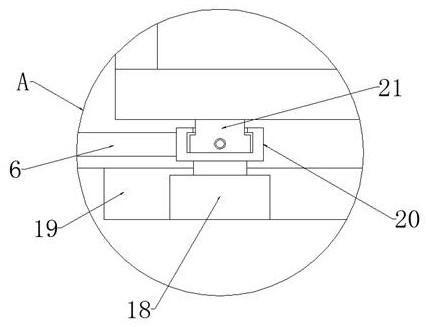

[0026] Embodiment 2: In the above embodiment, after the electronic main board is limited and fixed, the horizontal plate 20 can be moved by holding the push rod 6, so that the horizontal plate 20 drives the movable block 18 to slide inside the movable groove 19, thereby driving the placement of the splint 2 and Place the electronic main board on the splint 2 to move to the cutting disc 8, then start the driving motor 7, so that the driving motor 7 drives the first main pulley 15 and the main gear plate 9 to rotate, and the first main pulley 15 drives the first secondary pulley 14 through the transmission belt Rotate, the first secondary pulley 14 drives the cutting disc 8 to rotate again, so that the cutting disc 8 performs cutting operation on the electronic main board, and the main gear disc 9 drives the secondary gear disc 10 to rotate, and the secondary gear disc 10 drives the connecting rod 16 and the second main pulley 17 rotates, and the second main pulley 17 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com