Solid-liquid separator for kitchen waste

A technology for solid-liquid separators and kitchen waste, applied in presses, grain processing, manufacturing tools, etc., can solve problems such as being stuck between the auger and the inner wall, blocking the filter screen, and affecting the use effect. Achieve the effect of improving solid-liquid separation performance, improving discharge performance, and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

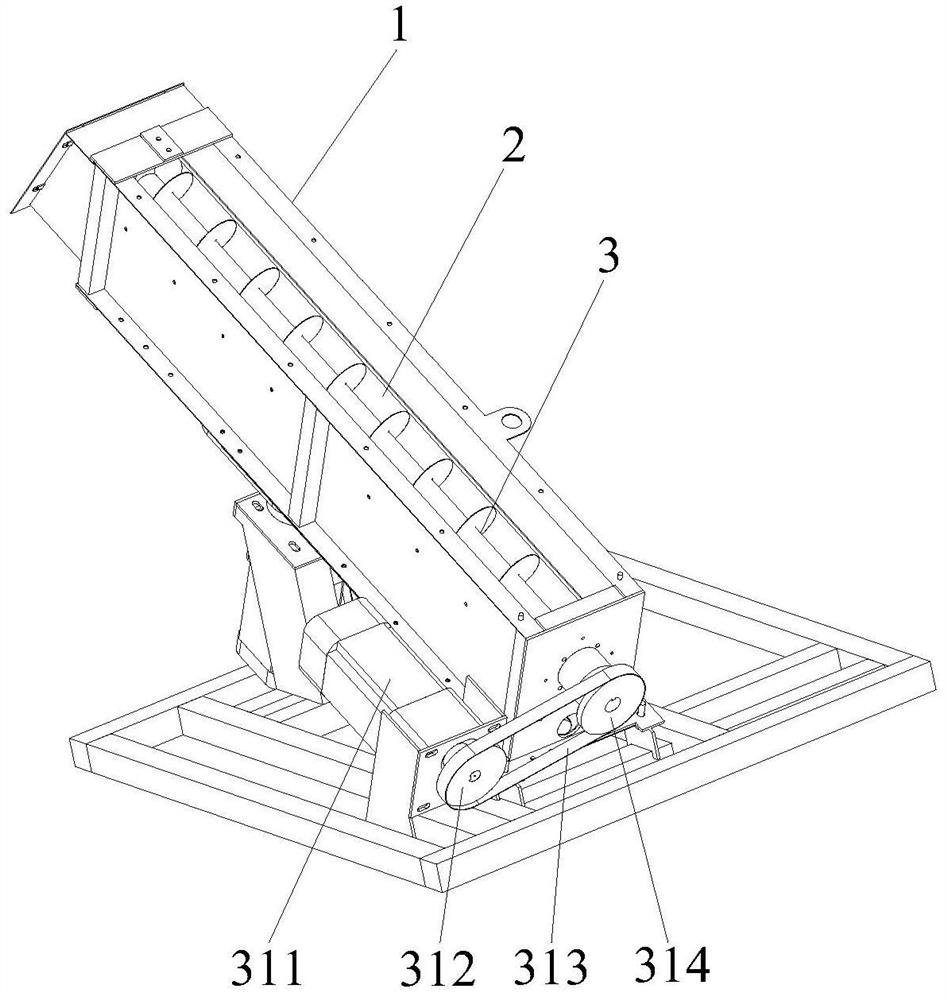

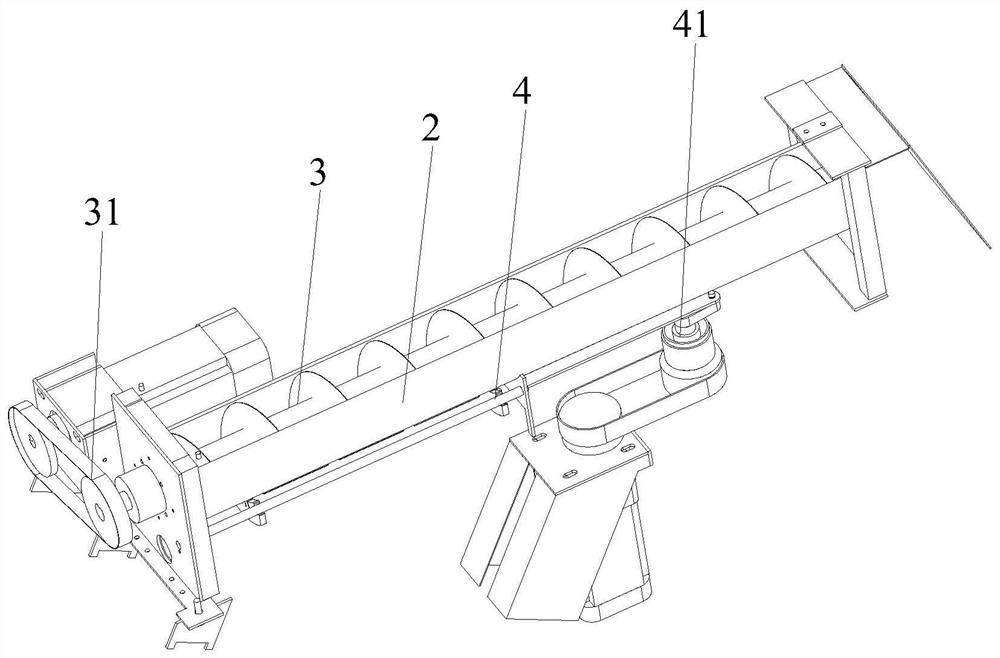

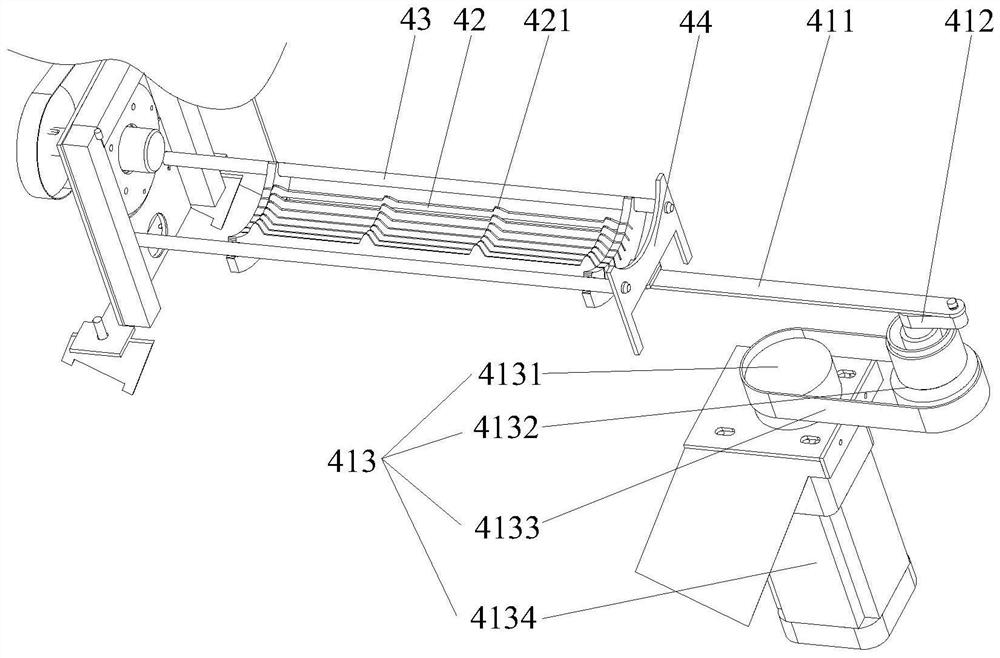

[0035] like Figure 1 to Figure 11 As shown, a kitchen waste solid-liquid separator provided by the present invention includes a body 1, a solid-liquid separation chamber 2 is provided in the body 1, and the solid-liquid separation chamber 2 is equipped with a conveying auger 3, and the kitchen waste After entering the solid-liquid separation chamber 2, the solid material in the kitchen waste is separated from the solid by the conveying auger 3, and transported along the length direction of the solid-liquid separation chamber 2, usually inclined upward, wherein the kitchen waste The liquid part of the remaining garbage is discharged downward due to gravity, and the gap between the conveying auger 3 and the inner wall of the solid-liquid separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com