Small water surface cleaning ship with flow guide device

A technology for a diversion device and a cleaning boat, which is applied to the cleaning of the open water surface, the load handling device, the hull, etc., can solve the problems of complicated collection and unloading process, small harvesting area, and high use cost, and achieves a simple setting method, The effect of increasing the collection width and ensuring the sailing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

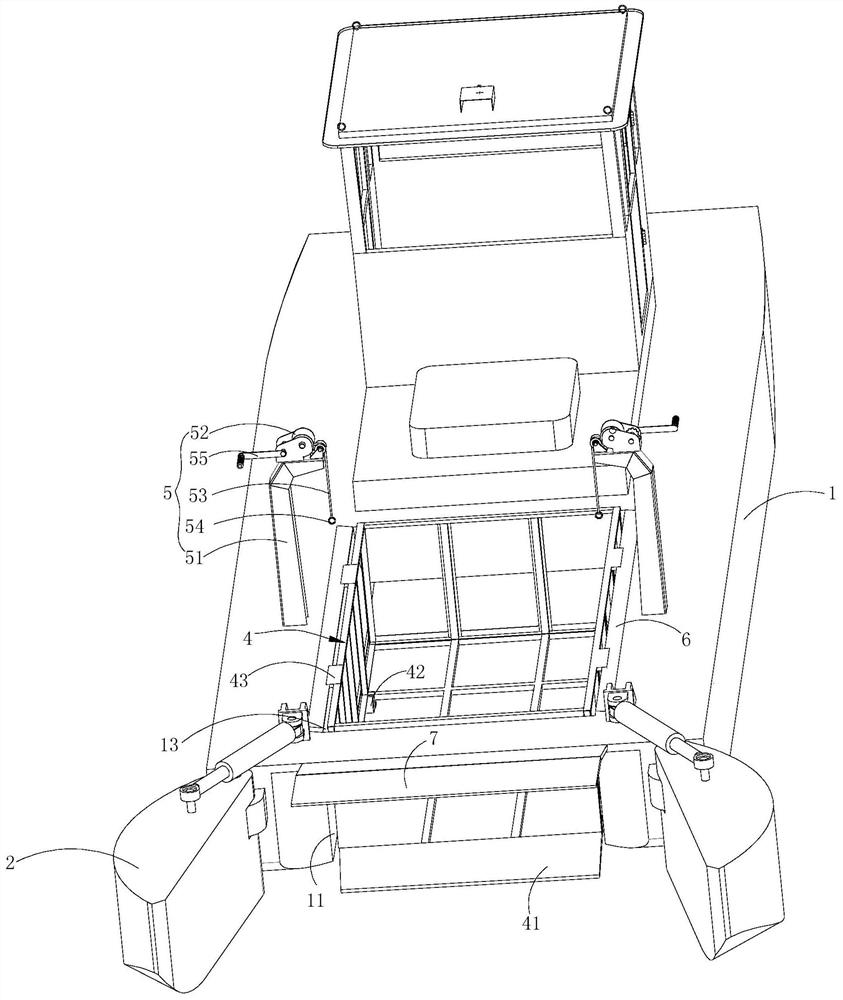

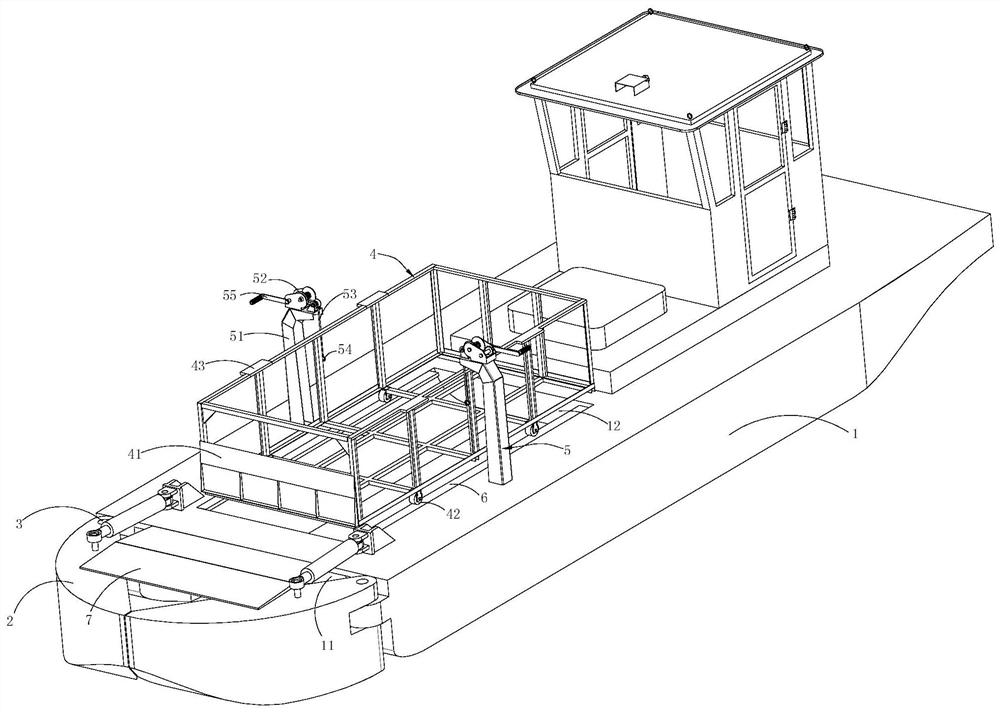

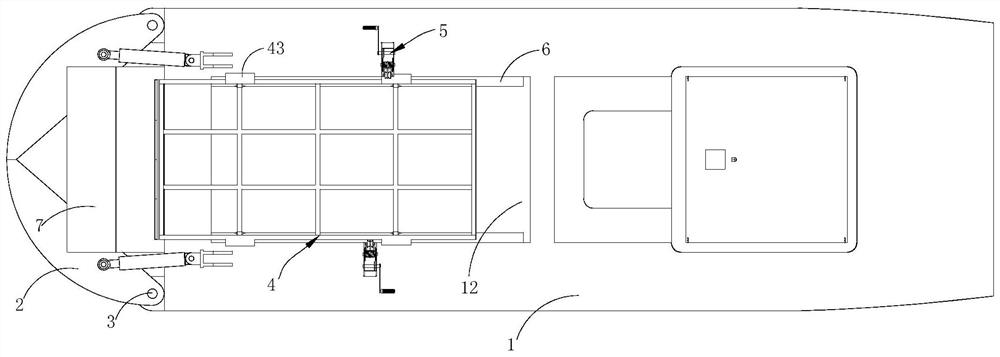

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] A small water surface cleaning boat equipped with diversion devices, see figure 1 , 2 As shown, including the hull 1, the bow of the hull 1 is provided with a gap 11, and the middle part of the hull 1 is provided with a recovery tank 12 communicating with the gap 11, and a flow guiding device is also installed on the hull 1.

[0024] The deflector includes a pair of mirror-symmetric deflectors 2, one end of the deflector 2 is installed on the front end of the hull 1 through a rotating shaft 3 arranged in the vertical direction, and the other end is a free end. The flow plate 2 is respectively arranged on the left and right sides of the gap 11, see figure 1 , 2 As shown, the deflector has two working states of unfolding and closing. When harvesting floating objects, the two deflectors 2 rotate outwards away f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap