Automatic assembly line plastic injection molding production line

An automatic assembly line and production line technology, applied in the field of machinery, can solve the problems of low production efficiency, high labor cost, unstable quality, etc., and achieve the effect of improving production efficiency and reducing personnel costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

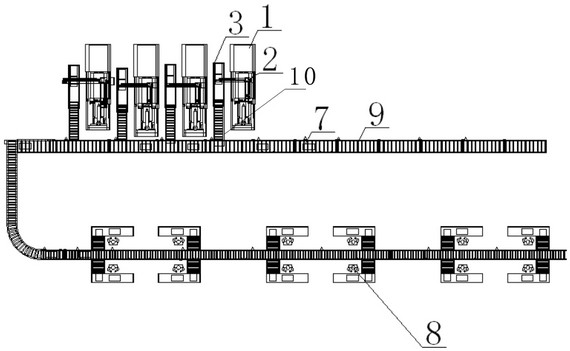

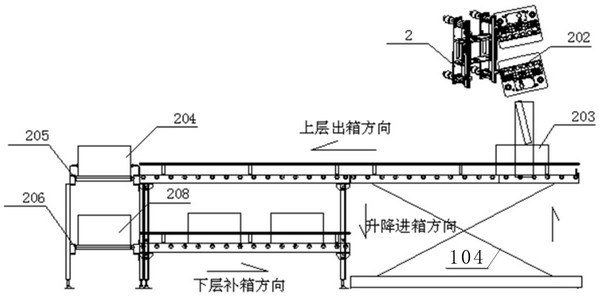

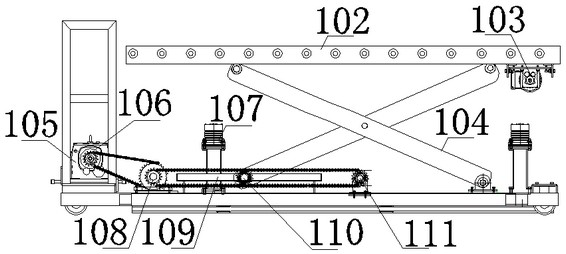

[0019] figure 1 , 2 Among them, the present invention includes a conveying main rail 9, three lifting rails 3, three injection molding machines 1, and three manipulators 2. The conveying main track 9 is a double-layer track, comprising a conveying track upper layer 205 and a conveying track lower layer 206 . The injection molding machine 1, the lifting track 3, and the injection molding machine 1 are all located at the side of the conveying main track 9, and the injection molding machine 1 corresponds to the lifting track 3 one by one. The sides of the upper layer 205 of the conveying track and the lower layer 206 of the conveying track are respectively provided with auxiliary rails 10 for docking with the lifting track 3 , and the axis of the roller table on the auxiliary rail 10 is perpendicular to the axis of the roller table of the upper layer 205 of the conveying track. The conveying main track 9 corresponds to each auxiliary track 10 and or the turning point of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com